In industrial plants, energy metering systems, and water or wastewater applications, inaccurate flow readings are a common complaint.

Very often, the first assumption is that the flow meter itself is faulty or poorly selected.

However, real field experience shows a different truth:

In most cases, inaccurate flow measurement is caused by improper installation and unfavorable process conditions — not by the instrument itself.

It is not unusual to see a flow meter perform accurately during factory testing or calibration, yet display large errors once installed on site. Even the most accurate instrument cannot deliver reliable results if the flow profile is distorted, the pipe is not fully filled, grounding is incorrect, or electrical noise interferes with the signal.

This article summarizes the most critical installation principles, common pitfalls, and practical field checks that can immediately improve flow measurement reliability.

1. Key Concepts Every Flow Measurement Engineer Should Know

Straight Pipe Length

Flow meters require a section of straight, unobstructed pipe upstream and downstream to establish a stable velocity profile.

Disturbances caused by elbows, valves, tees, reducers, pump outlets, or heat exchangers introduce swirl, asymmetry, and secondary flows, which lead to systematic measurement errors and unstable readings.

Pipe Diameter (D)

“D” refers to the internal diameter of the pipe.

For example, 10D upstream means a straight pipe length equal to ten times the pipe’s internal diameter before the flow meter.

Full Pipe Condition

For liquid applications, the measuring section must remain completely filled at all times.

Partially filled pipes, trapped air pockets, or two-phase flow conditions can cause severe errors or total measurement failure for electromagnetic, ultrasonic, and differential pressure flow meters.

Back Pressure

Adequate downstream back pressure helps:

Prevent gas release and flashing

Maintain a full pipe condition

Reduce cavitation and flow instability

Low back pressure, especially near open discharge points or high pipe elevations, often leads to air entrainment and unstable readings.

Grounding and Shielding

Many flow meters operate with very low signal levels.

For example, electromagnetic flow meters typically measure electrode signals in the millivolt range. Improper grounding, shielding, or cable routing allows electromagnetic interference from VFDs, motors, and relays to corrupt the signal, resulting in drift, noise, or zero instability.

2. Installation Location Check — Before Mounting the Meter

Finding a place where a meter can be installed is not the same as finding a place where it will measure accurately.

Before installation, engineers should quickly verify:

Process Conditions

Is the medium liquid, gas, steam, slurry, or multiphase?

Are temperature and pressure conditions stable?

Is there a risk of degassing, flashing, or condensation?

Are there sources of air, bubbles, or solids upstream?

Pipe Layout

Is sufficient straight pipe available?

Will the pipe remain fully filled during all operating modes?

Is the location close to strong electrical interference sources?

Is the meter installed near a pump suction, discharge, or control valve?

In many cases, choosing the correct installation location costs nothing, while correcting a poor location later can be expensive and time-consuming.

3. Managing Flow Disturbances

Any component that changes flow direction or velocity profile introduces disturbance:

Elbows

Control valves

Tees

Reducers / expanders

Pump and compressor outlets

General field recommendations:

Keep major disturbances as far upstream as possible

Avoid sudden throttling immediately downstream

Place control valves downstream of the meter when possible

Typical straight pipe guidelines:

| Flow Meter Type | Upstream | Downstream |

|---|---|---|

| Electromagnetic | ≥ 5D | ≥ 3D |

| Vortex / Ultrasonic | ≥ 10D | ≥ 5D |

| Orifice / Nozzle (DP) | ≥ 20D (typical) | ≥ 5D |

Longer straight runs are recommended when strong disturbances are unavoidable.

4. Common Installation Mistakes

High-Risk Locations

Pipe high points where air accumulates

Free discharge or open outlet lines with insufficient back pressure

Downhill sections where siphoning or negative pressure may occur

Locations immediately after control valves or pumps

Preferred Locations

Vertical pipes with upward flow

Horizontal pipes installed at low points

Bottom sections of U-shaped pipe layouts

Quick Field Checks

Does the pipe ever run partially empty during start/stop?

Is the downstream pressure close to atmospheric?

Are air vents or drains installed where needed?

Typical Remedies

Install a back pressure valve

Add air release valves at high points

Relocate the meter to a vertical upward flow section

5. Electromagnetic Flow Meter Installation Essentials

Electromagnetic flow meters rely on induced voltage generated by conductive liquids moving through a magnetic field.

This makes them highly sensitive to full pipe conditions and electrical integrity.

Best practices:

Ensure the pipe remains completely full

Avoid installation at high points or near open discharge

Position electrodes to minimize sediment buildup and gas exposure

Use proper grounding rings or electrodes for non-metallic pipes

Follow manufacturer grounding and shielding instructions

Route signal cables separately from power and VFD cables

Typical symptoms of installation issues:

Flow reading does not return to zero at no flow

Readings fluctuate with VFD frequency changes

Large transient spikes during equipment start/stop

In such cases, installation conditions should be checked before suspecting instrument failure.

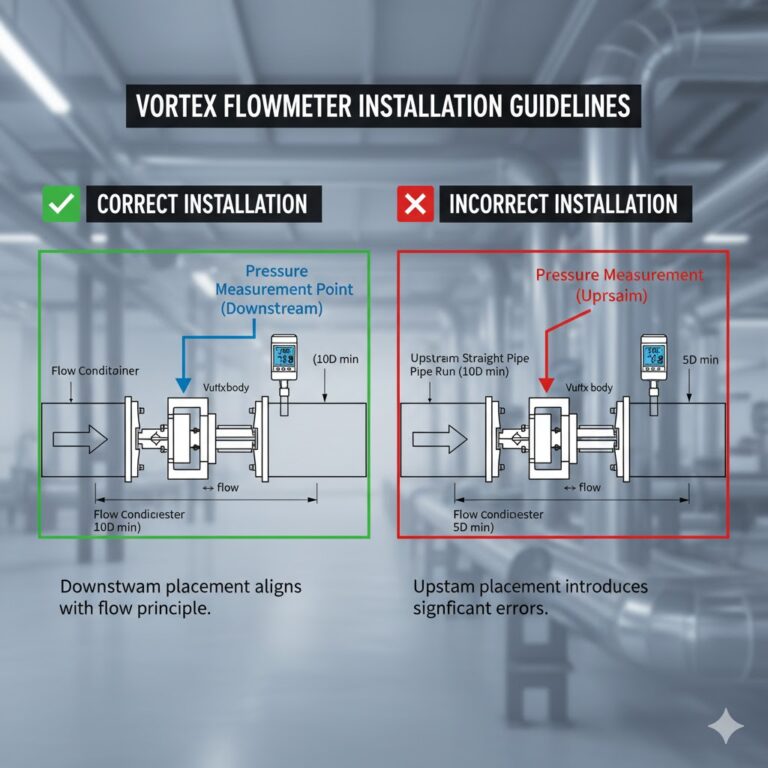

6. Vortex Flow Meter Installation Considerations

Vortex flow meters measure flow based on vortex shedding frequency.

They are particularly sensitive to vibration and unstable flow conditions.

Key points:

Avoid mounting on vibrating pipe sections

Keep distance from compressors, pumps, and unsupported piping

Place control valves downstream

For steam applications, ensure proper insulation and condensate management

Prevent two-phase flow for gas and steam services

When readings fluctuate, mechanical vibration and phase changes should be investigated first.

7. Ultrasonic Flow Meter Installation Tips

Clamp-on ultrasonic flow meters offer non-intrusive installation, but accuracy strongly depends on installation quality.

Critical factors:

Clean, smooth pipe surface

Avoid weld seams, corrosion, and thick coatings

Proper coupling gel application

Accurate input of pipe material, diameter, wall thickness, and lining

Verification of signal strength and quality indicators

Incorrect parameters result in incorrect calculations — even if the instrument itself is functioning perfectly.

8. Commissioning and Acceptance Checks

Before accepting flow measurement results:

Verify flow direction and signal mapping

Perform zero checks under no-flow conditions if possible

Analyze trends instead of single readings

Cross-check mass or volume balance within the system

Confirm logical consistency between multiple measurement points

These steps often reveal installation or configuration issues immediately.

9. Conclusion

Flow measurement accuracy is rarely achieved by purchasing a high-end instrument alone.

Accurate flow measurement is engineered — not bought.

By ensuring proper straight pipe lengths, full pipe conditions, correct grounding, vibration control, and accurate parameter settings, flow meters deliver stable and trustworthy data that supports safe operation, process optimization, and energy management.