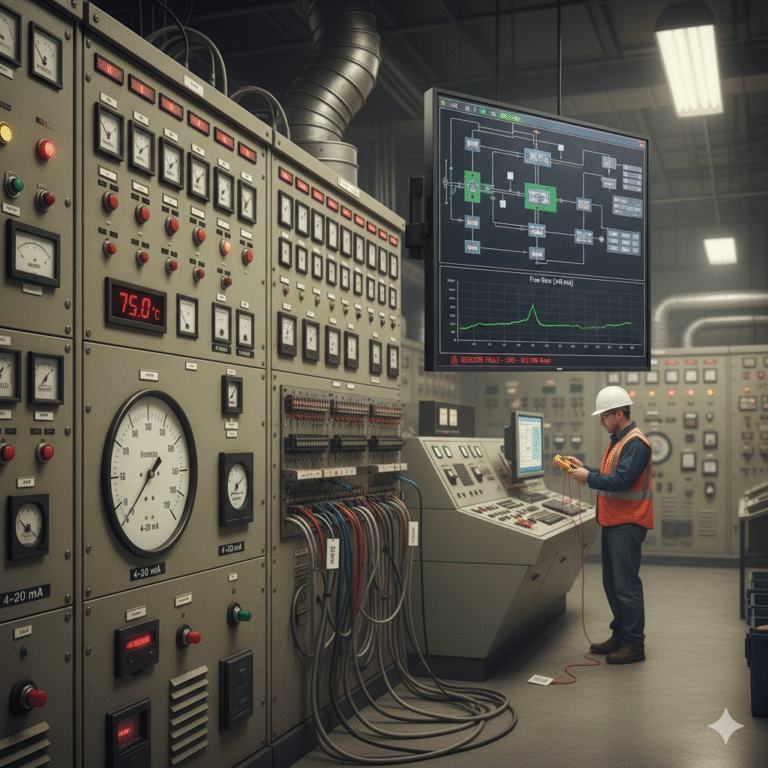

In modern industrial automation, digital communication protocols such as Modbus, Profibus, and HART have become increasingly popular. Yet, despite these advances, the 4–20 mA analog signal remains one of the most reliable and widely used methods for transmitting process variables such as pressure, temperature, flow, and gas concentration.

From gas detection systems (GDS) to level and temperature monitoring, this “classic” current loop continues to serve as the backbone of industrial measurement and control. Its enduring popularity lies in its stability, simplicity, and robustness, especially in environments where reliability is paramount.

1. Excellent Stability and Strong Noise Immunity

One of the most significant advantages of the 4–20 mA analog signal is its exceptional transmission stability and resistance to electrical noise.

Unlike voltage-based signals (e.g., 0–10 V), which are easily affected by voltage drops or electromagnetic interference (EMI/RFI), a current loop carries information as a constant current flowing through a circuit. This means that even if there is some resistance in the transmission line, the current value remains accurate as long as the voltage is sufficient to drive the loop.

As a result, 4–20 mA loops are ideal for long-distance transmission, often spanning several hundred meters without significant signal loss. In industrial environments filled with motors, variable frequency drives, and high-power electrical systems, this robustness against interference makes current loops the preferred choice for stable and precise measurement.

2. Linear and Intuitive Representation of Process Variables

Another key advantage of analog signal transmission is its direct and linear relationship with the measured variable.

In a typical configuration:

4 mA represents the lower measurement limit (e.g., 0% or zero level)

20 mA represents the upper limit (e.g., 100% or full-scale value)

Values between 4 and 20 mA vary proportionally with the process condition, allowing operators and control systems to easily interpret readings.

This linearity simplifies integration with control systems like DCS or PLC, where process data can be displayed directly on panels, trend charts, or HMIs without complex decoding. During troubleshooting, engineers can also interpret current readings intuitively—for example, a reading stuck at 12 mA might indicate a stable mid-range process, while a sudden drop to 3 mA could point to a sensor or wiring fault.

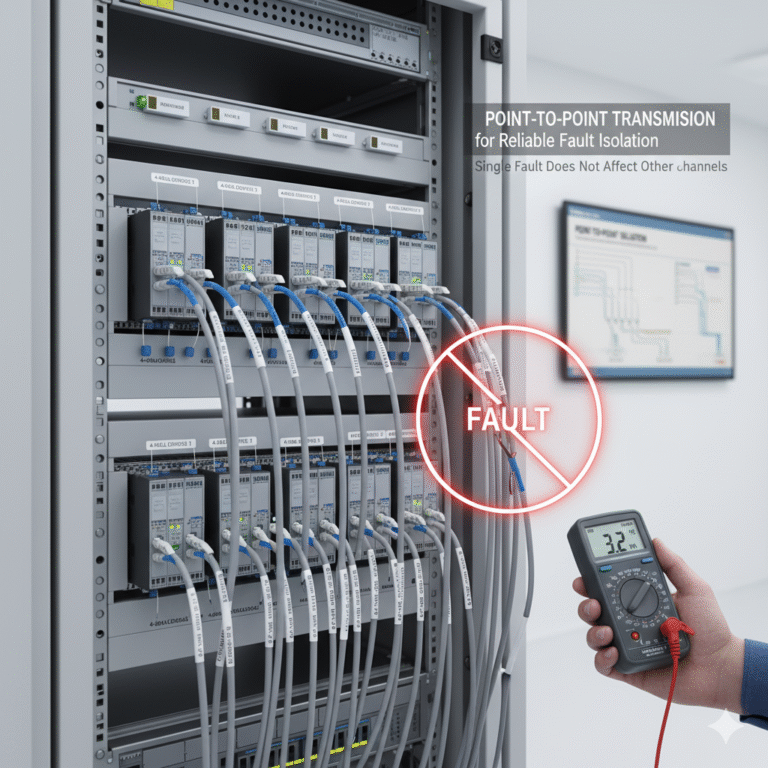

3. Point-to-Point Transmission for Reliable Fault Isolation

Each 4–20 mA signal loop is typically dedicated to a single transmitter, creating a point-to-point connection between the field instrument and the control system.

This independence provides a major safety advantage: if one signal line is damaged or a transmitter fails, it affects only that individual loop. Other channels remain unaffected.

In critical systems such as gas detection systems (GDS) or safety interlocks, this fault isolation is vital to ensure continuous monitoring and system reliability. It also simplifies maintenance — technicians can work on one loop without worrying about disrupting others, significantly improving overall system uptime.

4. Universal Compatibility and Easy Integration

The 4–20 mA current loop has become a universal standard in industrial instrumentation over decades of global use. Almost every type of PLC, DCS, indicator, or recorder can read or output this signal directly.

This universality eliminates the need for protocol converters or communication adapters, greatly simplifying integration between devices from different manufacturers.

For system retrofits or expansions, this is particularly valuable: existing control cabinets and wiring can often be reused, minimizing installation costs and downtime. In many modernization projects, engineers choose to retain 4–20 mA loops even when adding digital components, due to their simplicity and proven reliability.

5. Built-In Fault Detection Capability

The 4–20 mA standard also inherently supports fault detection.

When the signal falls below 4 mA (for instance, 0–3.5 mA), it usually indicates a fault condition—such as a broken wire, power failure, or sensor malfunction. Modern control systems can easily detect these out-of-range values and trigger alarms or maintenance notifications automatically.

This built-in diagnostic feature prevents false readings and helps operators quickly distinguish between “process abnormalities” and “instrumentation failures,” ensuring safety and accuracy.

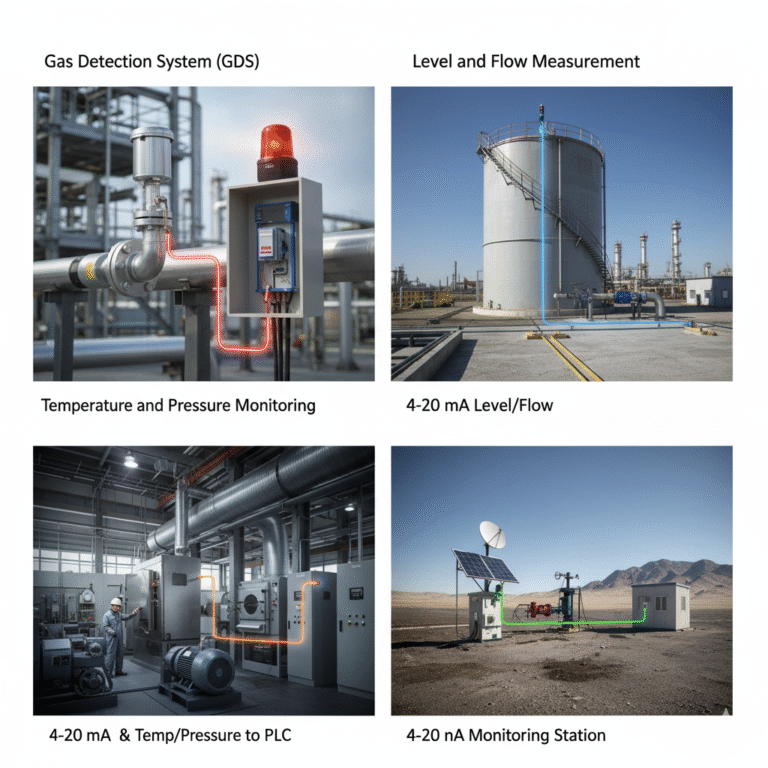

6. Real-World Applications of 4–20 mA Signals

The simplicity and dependability of analog current loops have made them indispensable across numerous industries:

Gas Detection Systems (GDS): Continuous monitoring of toxic or combustible gases where reliability and isolation are crucial.

Level and Flow Measurement: Long-distance signal transmission from tanks, wells, and pipelines in oil, water, and chemical plants.

Temperature and Pressure Monitoring: Integration with PLCs in harsh or noisy environments where digital communication may fail.

Remote or Hazardous Locations: Sites without stable communication networks often rely on current loops for accurate feedback to the control room.

In each of these cases, the 4–20 mA system provides a robust, noise-resistant, and maintenance-friendly solution that continues to outperform newer alternatives under demanding conditions.

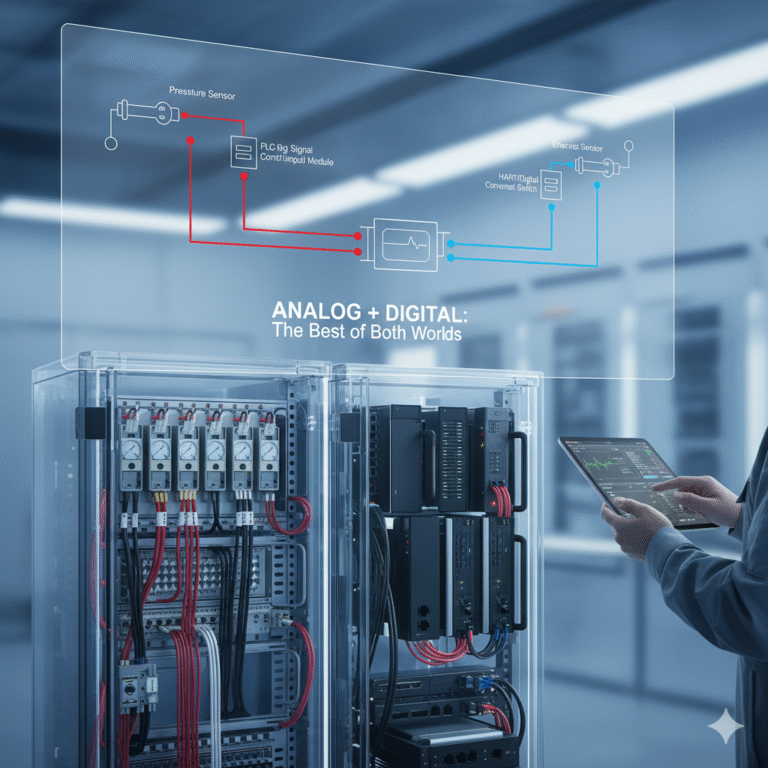

7. Looking Ahead: Analog and Digital Coexistence

While industrial networks are evolving toward digital and smart communication protocols, the 4–20 mA analog signal will not disappear anytime soon.

Its strengths—simplicity, universality, and reliability—make it an irreplaceable foundation for many measurement and control systems. In fact, modern “smart” transmitters often combine 4–20 mA analog output with HART or digital overlays, offering the best of both worlds: analog stability plus digital diagnostics.

In safety-critical or resource-limited environments, the analog loop remains the most dependable choice—a proven technology that continues to evolve while staying true to its fundamental purpose: accurate, reliable, and safe signal transmission.

Conclusion

The enduring success of the 4–20 mA analog signal in industrial automation is no coincidence.

Its resistance to interference, linear behavior, independent transmission, and built-in diagnostics make it the gold standard for reliable process communication.

As industries move toward smarter and more connected systems, analog current loops will continue to coexist with digital technologies—serving as the backbone of process control where reliability simply cannot be compromised.