The evaporation process is an important process of chlor-alkali production, the accurate measurement of the liquid level of each evaporation tank in the process is the key to realizing the caustic soda evaporation process in the alkali automation production.

So that its level measurement has also become a relatively important thing for each enterprise, once a customer asked us which level meter is the most suitable for measuring caustic soda evaporation tank, the answer we gave according to its specific situation is the guide wave radar level meter, today we will understand why the guide wave radar level meter is the most suitable from the theoretical knowledge sector.

There are many types of liquid-level instruments, and each has its own advantages under different working conditions. However, the working conditions of the evaporation process are complex, and the alkaline liquid is characterized by high temperature, high concentration, strong corrosiveness, and easy crystallization.

These characteristics can lead to high instrument failure rates, high maintenance, short service intervals, and maintenance difficulties. Under such conditions, such as electrode level switches and capacitance level meters, it is impossible to monitor the level changes in the tank in real-time, and the electrode surface is prone to salt, and false liquids are often measured, causing the switch valve to fail, which is very detrimental to the production operation.

The guided wave radar level meter is a detection instrument that can meet high temperatures, strong corrosion, and crystallization conditions at the same time. The guided wave radar level meter can measure many different media, including liquids, solids, particles, and powders, independent of changes in dielectric constant, temperature, pressure, density, and other conditions.

The signal is stable and accurate, and the signal transmission in the guided wave probe is unaffected by fluctuations in the level of the tank and obstacles. It is particularly suitable for measuring media containing vapor, mist, and foam, where mist and foam have no effect on the measurement. It also has low energy consumption.

The signal energy output from the guided wave radar level meter to the guided wave probe is very small so a loop power supply is used instead of a separate AC power supply, thus saving installation costs considerably.

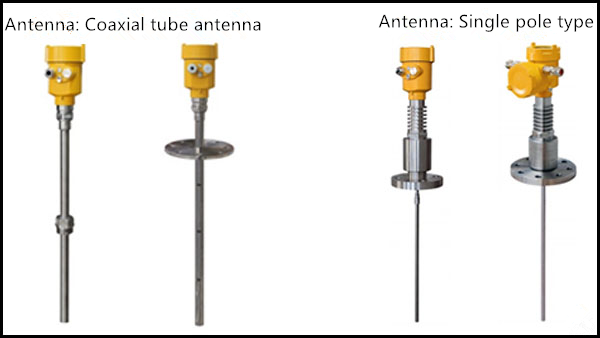

However, there are points that need attention. If the level measurement distance of the evaporation tank is relatively short, the probe of the guided wave radar level meter should be selected as a rod type.

The characteristics of the working conditions in the evaporation tank are increasing temperature and increasing corrosion, so the material of the wave-guide probe cannot only use conventional corrosion-resistant metal materials.

To choose the probe material for 304 stainless steel lined with PTFE, PTFE has good corrosion resistance to all concentrations of alkali, and PTFE is also very resistant to wear and tear and can resist the alkali in the boiling of the waveguide probe wash.

Both corrosion and abrasion resistance can meet the needs of working conditions and improve the life cycle of the level meter. The probes are easy to remove and replace.

Once the probes are damaged, they can be replaced without having to replace the whole instrument, thus greatly reducing the maintenance costs of the instrument.

So in summary, the guided wave radar level meter is well suited to the caustic soda evaporation process level measurement, but special attention needs to be paid to the corrosive nature of the medium and other characteristics in order to achieve the best measurement results.