Asphalt storage tanks present unique challenges for level measurement due to their high temperatures (130-230°C), high viscosity, tendency to adhere to surfaces, and volatile compounds. Therefore, the key principles for selecting a measurement method are “non-contact, high temperature tolerance, and resistance to interference.” Based on adaptability, stability, and maintenance cost, the guided wave radar level transmitter (especially guided wave radar) is the optimal choice. Following this, servo level transmitters are recommended for high-precision applications. Other methods have significant limitations.

1. First Choice: Guided Wave Radar Level Transmitter (Combination of Non-contact and Contact Methods)

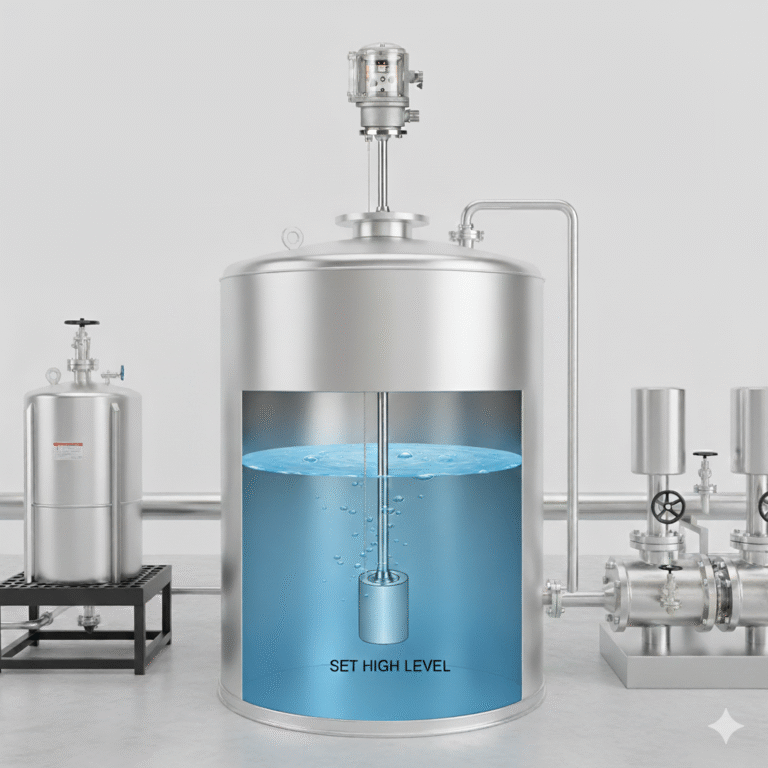

Guided wave radar (GWR) uses a metal waveguide rod (or cable) to transmit signals, making it a perfect fit for the characteristics of asphalt. It is the most widely used solution today.

Key Advantages:

Resistance to Adhesion: The waveguide rod can be inserted directly into the asphalt, allowing signals to transmit even if small amounts of asphalt adhere to the rod. Asphalt’s high dielectric constant does not interfere with signal reflection, making this solution far superior to standard non-contact radar (which is prone to interference from adhesion).

High Temperature Tolerance & Resistance to Volatile Compounds: The system can withstand temperatures above 300°C, and the waveguide structure remains unaffected by the vapors or gases inside the tank, ensuring signal stability.

Measurement Range & Accuracy: The system covers a measurement range from 0.5 to 20 meters with an accuracy of ±5mm, making it suitable for both vertical and horizontal tanks. It is particularly effective in tanks with agitators or coils, as the waveguide rod can avoid obstacles.

Considerations:

Choose a rigid rod type for high viscosity, easily solidifying asphalt or a cable type for deep tanks. Ensure that the waveguide rod is installed vertically and does not come into contact with the tank’s bottom or heating elements.

2. Second Choice: High-Frequency Pulse Radar Level Transmitter (Pure Non-contact Method)

If the tank structure is simple (without complex obstacles) and the asphalt surface is relatively stable, high-frequency pulse radar (26GHz or 78GHz) is an ideal choice.

Key Advantages:

Non-contact Measurement: The probe never contacts the asphalt, completely avoiding adhesion or sticking problems, and requires minimal maintenance (only periodic cleaning of condensation on the probe’s surface).

Strong Interference Resistance: High-frequency signals have shorter wavelengths (e.g., 78GHz wavelength is about 4mm) and are less affected by small obstacles (such as tank supports), making them ideal for large, open storage tanks. These signals can be filtered out using advanced algorithms.

Considerations:

Avoid positioning the probe near the inlet (to prevent asphalt splashing onto the probe) or in areas with high vapor concentrations. If there is a large amount of foam (potentially produced during asphalt mixing), choose a model with foam tracking capabilities.

3. Specific Scenario Solution: Servo Level Transmitter (High-Precision Measurement Requirements)

For trade settlements or precise measurement (accuracy of ±1mm), a servo level transmitter is the only choice, but it comes with higher maintenance costs.

Key Advantages:

Top-Level Accuracy: This system measures the level using buoyancy and servo motors, unaffected by asphalt’s viscosity or temperature, making it ideal for accurate measurement during asphalt loading and unloading operations.

Key Disadvantages:

Contact Measurement: The heavy-duty weight and steel band are prone to asphalt sticking, requiring monthly cleaning to prevent blockages or inaccuracies. This results in much higher maintenance than radar-based solutions.

High Cost: The equipment is 2-3 times more expensive than radar, and in high-temperature environments, the steel band may deteriorate quickly, leading to high replacement costs.

4. Not Recommended: Solutions with Significant Limitations

Ultrasonic Level Transmitters: The high temperature causes significant signal attenuation, and volatile gases and wall adhesion interfere greatly, resulting in high measurement errors (>5%). These are not suitable for asphalt tanks.

Float/ Magnetic Flip-Level Transmitters: The float is prone to sticking to the asphalt, while the magnetic flip-tube can become clogged with scale. In colder temperatures, asphalt can solidify and damage the equipment.

Differential Pressure Level Transmitters: The pressure tubes are prone to being clogged with asphalt, and temperature fluctuations cause density changes, requiring frequent purging and calibration, resulting in higher maintenance than benefit.

Quick Selection Guide:

| Scenario | Recommended Solution | Key Reason |

|---|---|---|

| General Storage Tank, Routine Monitoring | Guided Wave Radar Level Transmitter | Resistance to adhesion, high temperature tolerance, low maintenance |

| Large Storage Tank, Simple Structure | High-Frequency Pulse Radar Level Transmitter | Non-contact, interference resistance, suitable for long distances |

| Trade Settlements, High-Precision Measurement | Servo Level Transmitter | Accuracy of ±1mm, meets measurement needs |

| Low-Cost Temporary Monitoring (Not Recommended) | Magnetostrictive Level Transmitter (with purging) | Only suitable for short-term use, requires frequent maintenance |

Conclusion:

The guided wave radar level transmitter is the “best value for money” option for asphalt storage tanks, balancing stability, adaptability, and ease of maintenance. Unless there is a critical need for high precision (such as trade settlements), it should be the first choice.