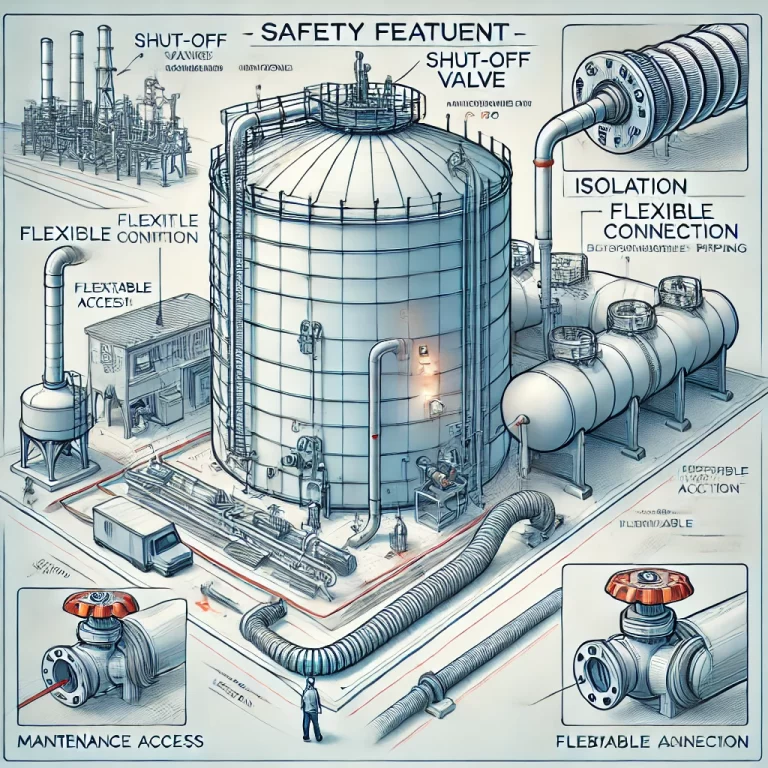

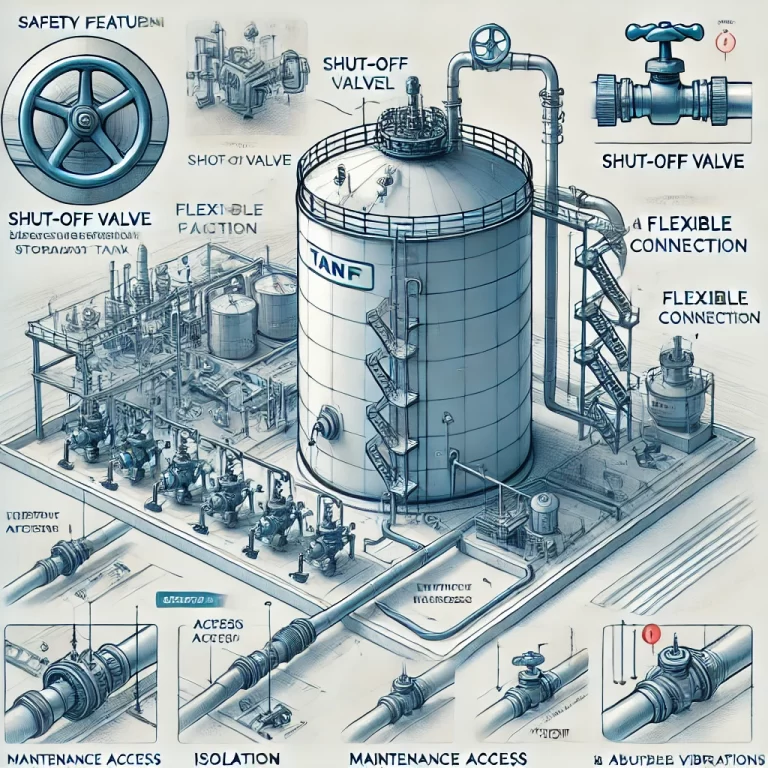

The placement of a shut-off valve in a tank system is a critical design consideration, especially when flexible connections are involved. The general consensus among engineers is that the shut-off valve should be placed before the flexible connection. This article explores the reasoning behind this recommendation in detail and highlights the implications for safety, functionality, and maintenance.

Key Reasons for Positioning the Shut-Off Valve Before the Flexible Connection

1. Effective Isolation of the Tank

The primary function of a shut-off valve is to isolate the tank in case of an emergency or for routine maintenance. By positioning the valve directly at the tank outlet and before the flexible connection, you ensure that any downstream issues, such as leaks or ruptures in the piping or flexible connection, can be quickly mitigated.

If the valve were located after the flexible connection, isolating the tank would not protect the flexible connection itself, leaving it exposed to potential damage or uncontrolled flow.

2. Protection of the Flexible Connection

Flexible connections are installed to absorb movement, such as thermal expansion, contraction, or vibrations. However, they are often the weakest link in the pipeline system. Situating the shut-off valve before the flexible connection helps reduce the risk of damage to the connection during emergencies or high-pressure scenarios.

For instance:

- In case of sudden overpressure or mechanical stress, the shut-off valve can be closed immediately, shielding the flexible connection from further strain.

- Without a valve upstream, a compromised flexible connection could lead to hazardous material leaks, environmental damage, or safety risks to personnel.

3. Enhanced Safety During Maintenance

Routine maintenance often involves work on downstream components such as piping, pumps, or the flexible connection itself. With the valve upstream of the flexible connection, the tank can be fully isolated, ensuring a safer working environment for technicians. This setup reduces the risk of accidental fluid release during maintenance operations.

Practical Design Considerations

While the general guideline is to place the shut-off valve before the flexible connection, certain factors can influence the exact configuration:

- Tank Design and Layout: If space is limited, the valve and flexible connection may need to be closely positioned. In such cases, care must be taken to ensure that the valve remains easily accessible for operation.

- Fluid Type and Pressure: High-pressure or hazardous fluids may necessitate additional safety features, such as double-block-and-bleed systems, to complement the shut-off valve.

- Regulatory Requirements: Local codes and industry standards might dictate the placement of shut-off valves and flexible connections, particularly in sensitive industries like oil and gas or chemicals.

Advantages of Proper Placement

- Improved Safety: Quick isolation of the tank minimizes the risk of accidents.

- Prolonged Equipment Life: Protecting the flexible connection reduces wear and tear, leading to lower maintenance costs.

- Operational Efficiency: Maintenance and emergency response are streamlined when the valve is positioned before the flexible connection.

Conclusion

In most scenarios, it is advisable to install the shut-off valve before the flexible connection in a tank system. This configuration provides better control over the tank’s contents, protects vulnerable components like the flexible connection, and enhances safety during maintenance and emergency situations.

Ultimately, the specific design of any tank system should take into account the operating conditions, fluid properties, and applicable standards. Consulting with experienced engineers and adhering to best practices ensures the system is both safe and efficient.