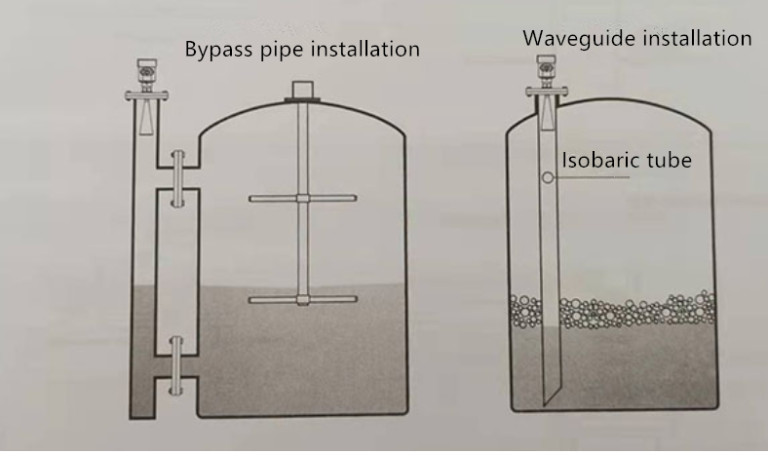

When there are some special conditions in the level vessel, a bypass tube installation is required to ensure the normal operation and accurate measurement of the radar level meter. In this paper, we will discuss the circumstances under which the radar level meter needs to be installed with a bypass tube, and give examples of its actual measurement cases.

A radar level meter, a widely used instrument for level measurement, is usually installed above the vessel and measures the level height by transmitting and receiving microwave signals.

However, in some special cases, direct installation above the vessel may be subject to some limitations, so a bypass tube installation is required.

High or low-temperature media: Some liquid media have extremely high or low temperatures that are outside the normal operating temperature range of radar level meters. In this case, the liquid can be directed to the outside of the pipe through a bypass tube to avoid direct exposure to high or low-temperature media and to protect the normal operation of the radar level meter.

High-pressure media: High pressure exists in some liquid media and direct exposure to high-pressure media may cause damage or even danger to the radar level meter.

By installing a bypass tube, the pressure on the level meter can be reduced to ensure its safe work. Corrosive media: Some liquid media are highly corrosive, and direct exposure to corrosive media may cause damage to the radar level meter.

By installing a bypass tube, the medium can be directed to the outside of the pipe, away from the level meter, thus protecting it from the effects of corrosion.

In a chemical company’s storage tank system, there are high-temperature and corrosive liquid media. Since the radar level meter could not be directly exposed to the high temperature and corrosive media for measurement, they needed to use a bypass tube installation.

They selected a radar-level meter suitable for high temperature and corrosive media and installed a bypass tube in the upper part of the tank.

Through the bypass tube, the liquid is directed outside the pipe and away from the level meter. This allows the radar level meter to perform accurate level measurements in a safe environment.

By monitoring the data provided by the level meter in real-time, the chemical company can keep track of the changes in the liquid level inside the storage tank and make corresponding adjustments and decisions based on the data in order to optimize the production process and ensure safety.

In some special cases, such as the presence of high temperature, low temperature, high pressure, or corrosive media, a bypass tube installation is required to ensure the safe working and accurate measurement of the radar level meter. Through the bypass tube, the medium can be directed to the outside of the pipe, away from the level meter, thus protecting the level meter from the special medium.