1. A Revolution in Industrial Communication

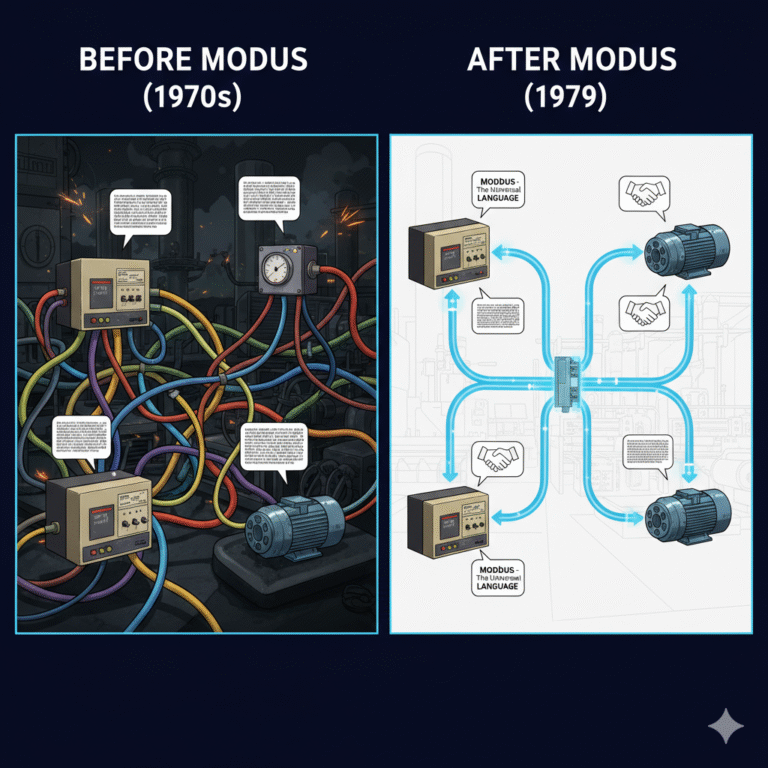

In the realm of industrial automation, communication protocols are as essential as language itself. In 1979, Modicon (now Schneider Electric) introduced the Modbus protocol, designed to solve the problem of “incompatibility” between devices.

At that time, each manufacturer used proprietary protocols, making it difficult for devices from different companies to communicate. The birth of Modbus introduced the first standardized communication method for industrial equipment.

Its three major advantages quickly made it popular:

Open and Free – No licensing or authorization required.

Simple Structure – Easy to implement in both hardware and software.

High Compatibility – Supports multi-brand, multi-generation, and multi-platform devices.

Over forty years later, Modbus has evolved beyond a mere communication protocol, becoming the “bridge language” for industrial systems. From PLCs to smart instruments, from DCS to cloud platforms, Modbus is now ubiquitous in industrial automation.

2. Core Mechanism

Modbus uses a strict Master-Slave or Client-Server model, ensuring predictable and controlled communication, a hallmark of “deterministic communication” in the industrial sector.

Master (Client)

The Master actively initiates communication requests (e.g., “read register,” “write coil”), controlling the communication flow. Common masters include PLCs, SCADA systems, and host computers.Slave (Server)

The Slave responds passively to Master requests without initiating communication. Common Slaves include sensors, actuators, inverters, and instruments. Communication is one master to many slaves—a network can have one Master and up to 247 Slaves (address range 1–247).Broadcast Mechanism

Address 0 is reserved as a “broadcast address.” When the Master sends a command to address 0, all Slaves execute the command but do not respond. This is useful for bulk control operations, such as resetting multiple devices simultaneously.

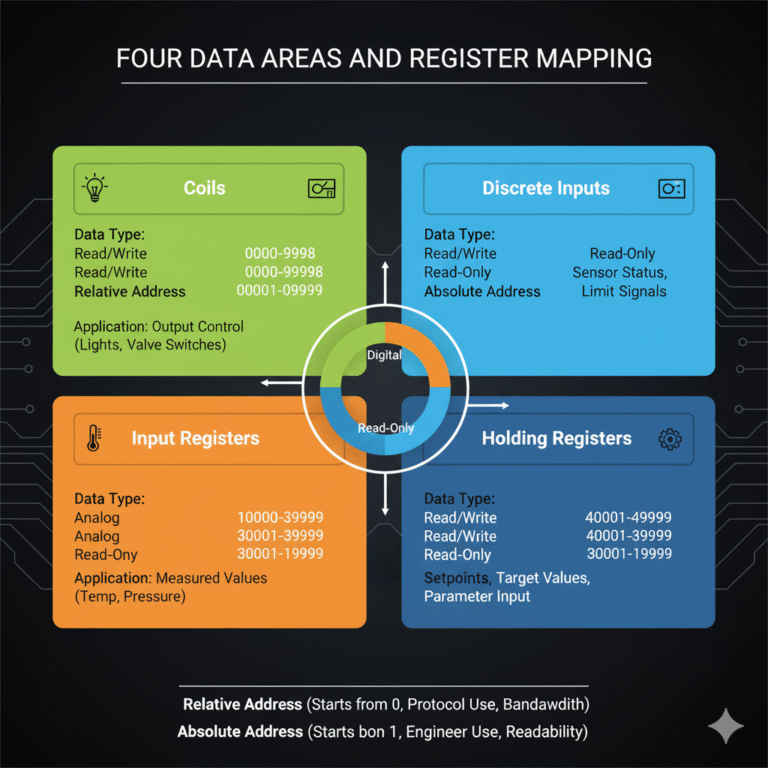

3. Four Data Areas and Register Mapping

Modbus abstracts device data into four types of registers, logically classified into two dimensions: digital/analog and read/write permissions.

| Storage Type | Data Type | Read/Write | Address Range | Application Example |

|---|---|---|---|---|

| Coils | Digital | Read/Write | 00001–09999 | Output control (e.g., lights/valve switches) |

| Discrete Inputs | Digital | Read-Only | 10001–19999 | Sensor status, limit signals |

| Input Registers | Analog | Read-Only | 30001–39999 | Measured values (e.g., temperature, pressure) |

| Holding Registers | Analog | Read/Write | 40001–49999 | Setpoints, target values, parameter input |

Relative Address vs. Absolute Address

Relative Address: Used in the protocol (starting from 0) to reduce bandwidth.

Absolute Address: Used by engineers for configuration (starting from 1), offering easier readability.

This design allows both Master and Slave to map data using a unified structure model, essential for cross-brand interoperability.

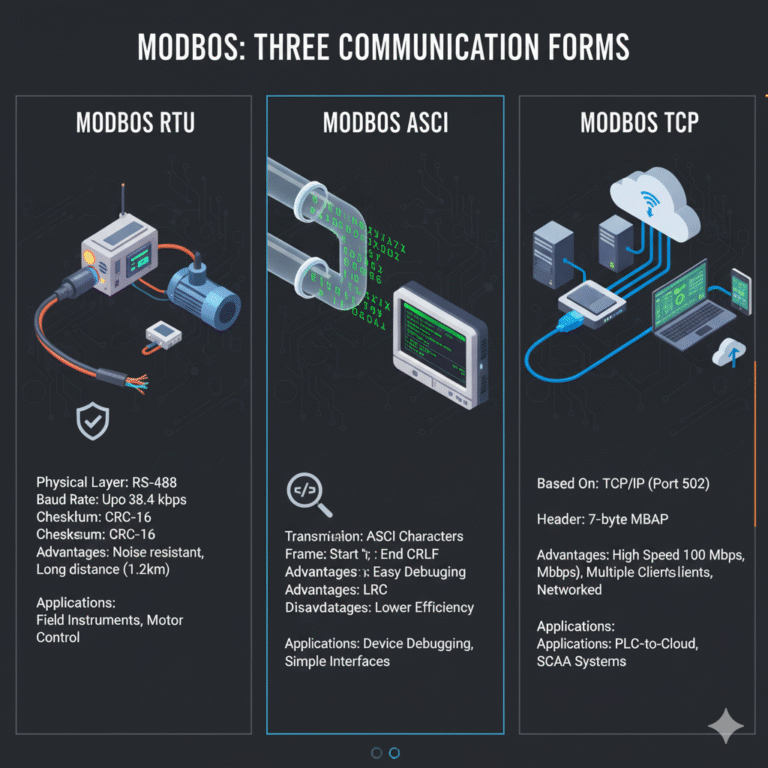

4. Three Communication Forms

Modbus RTU

Physical Layer: RS-485 (half-duplex) or RS-232

Baud Rate: Common rates include 9600, 19200, and 38400 bps (must match between Master and Slave)

Parity: Even, Odd, or None with 1 or 2 stop bits

Checksum: CRC-16 (Cyclic Redundancy Check)

Advantages: High noise resistance, compact frame structure, transmission distance up to 1200 meters, and supports up to 32 devices.

Applications: Production line equipment, inverter control, field instrument communication.Modbus ASCII

Transmission: ASCII characters (0–9, A–F)

Frame Format: Starts with “:”, ends with CRLF (Carriage Return Line Feed)

Checksum: LRC (Longitudinal Redundancy Check)

Advantages: Easy to debug due to character-based transmission, but frame size is twice that of RTU, leading to lower transmission efficiency.

Applications: Low-speed communication, device debugging, and educational experiments.Modbus TCP

Based on TCP/IP stack, using port 502, Modbus TCP adds a 7-byte MBAP header to the Modbus application layer.Advantages: High-speed communication (10/100 Mbps), multiple clients can access concurrently, and it eliminates physical limitations of traditional serial communication.

Applications: Connecting PLCs, SCADA systems, and cloud platforms.

5. Data Reliability

To ensure data integrity during transmission, Modbus employs two different checksum methods: CRC for RTU mode and LRC for ASCII mode. These methods ensure stable and accurate data transmission even in noisy industrial environments.

CRC-16 (Modbus RTU): Uses polynomial division for error detection and can detect single-bit errors and burst errors, ensuring highly reliable communication.

LRC (Modbus ASCII): A simpler error detection method using a cumulative sum of all data bytes and taking its two’s complement.

6. Typical Applications

| Application Area | Typical Devices | Communication Mode | Key Features |

|---|---|---|---|

| Smart Manufacturing | PLCs, Robots, HMIs | Modbus TCP | Remote control & data acquisition |

| Energy Management | Smart meters, Thermostats | RTU/TCP | Energy monitoring & load optimization |

| Building Automation | HVAC, Lighting Systems | RTU | Integration in BMS systems |

| Water Treatment | Flow meters, Pump stations | RTU | High noise resistance |

| Edge Computing | Industrial gateways, Modules | TCP/MQTT | Cloud data & remote monitoring |

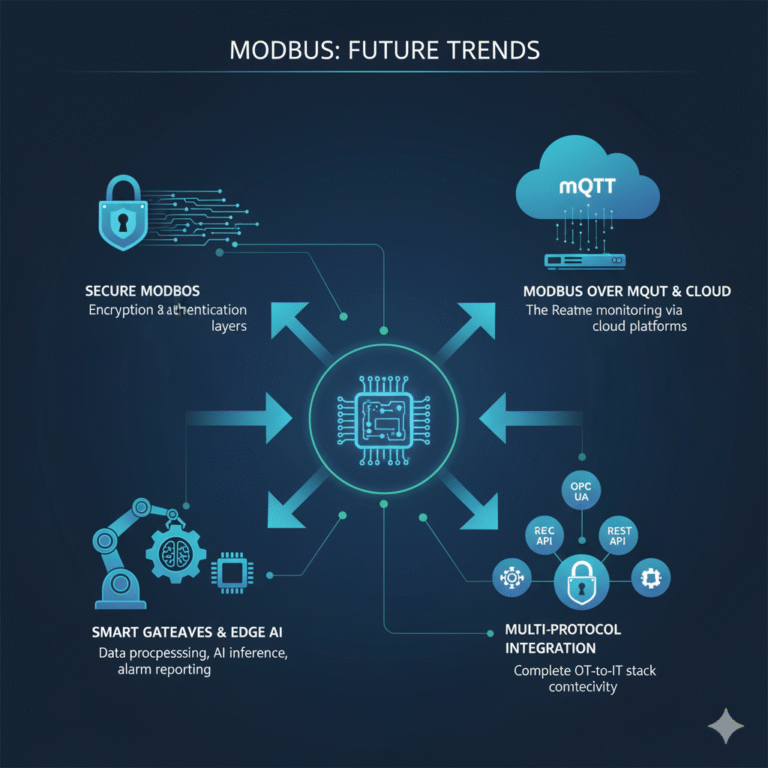

7. Future Trends

Secure Modbus – Introducing encryption layers and authentication to prevent eavesdropping and spoofing, enhancing industrial security.

Modbus over MQTT – Using MQTT gateways to upload Modbus data, enabling cloud-based real-time monitoring.

Smart Gateways & Edge AI – Next-generation gateways not only forward protocols but also preprocess data, perform AI inference, and report alarms at the edge.

Multi-Protocol Integration – Combining Modbus with protocols like OPC UA, REST API, and Profinet for complete OT-to-IT stack connectivity.

8. Conclusion

Without Modbus, the industrial world would be like a planet where every brand speaks a different dialect. Through its simplicity, stability, and compatibility, Modbus has supported the industrial communication system for decades. Now, with upgrades to cloud, security, and intelligence, it continues to be the “universal language” of smart manufacturing and the Industrial Internet.

No matter how industrial protocols evolve, Modbus’s deterministic logic and open philosophy will remain its most valuable legacy.