Hazard and Operability (HAZOP) analysis is one of the most essential tools in process safety management.

However, many companies still struggle to determine when it must be conducted — is it mandatory only during design? Should it be repeated during operation? What if personnel or process conditions change?

This article summarizes key regulatory requirements and practical triggers for HAZOP analysis based on multiple authoritative Chinese safety management guidelines, helping you understand when and how often HAZOP must be performed to stay compliant and safe.

HAZOP in a Nutshell

HAZOP (Hazard and Operability Study) is a systematic technique used to identify potential hazards and operability issues in chemical processes.

It helps engineers anticipate deviations from design intent, evaluate their consequences, and define corrective measures.

In China’s chemical industry, HAZOP is now a mandatory part of safety design, operation, and re-assessment for certain high-risk installations.

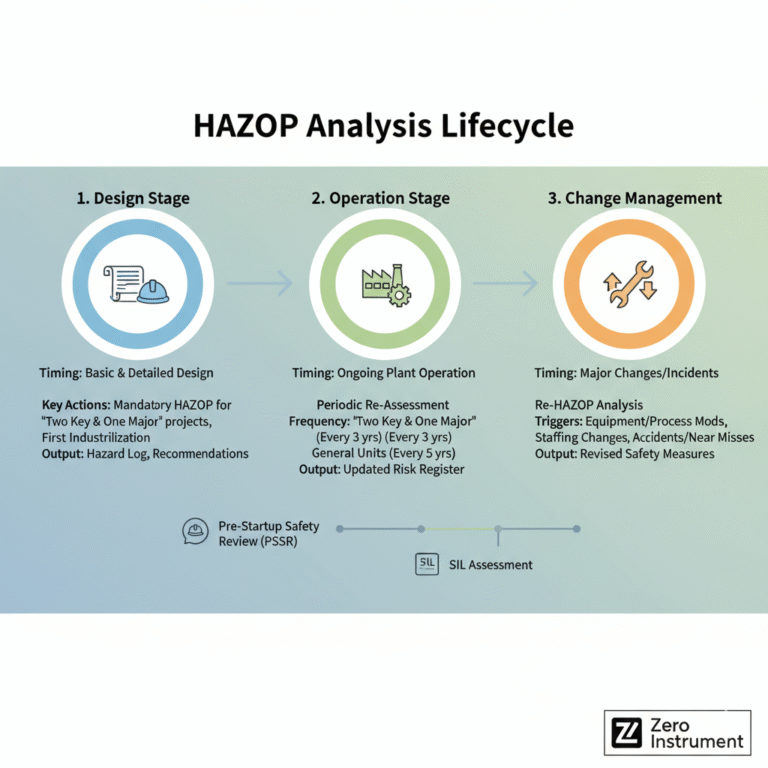

1. During the Design Stage: Mandatory for “Two Key and One Major” Projects

According to several directives — including AQ/T 3034-2022, AQ/T 3033-2022, and Emergency [2022] No. 52 — HAZOP analysis must be conducted during the basic design stage for the following cases:

Projects involving “Two Key and One Major” elements:

Key regulated hazardous chemicals

Key regulated chemical processes

Major hazard installations

First-time industrialization projects (new technologies or first commercial application)

Design packages involving major hazard sources (HAZOP or equivalent risk analysis required)

Key Point:

The design company should organize the HAZOP study, while the project owner must ensure participation of personnel with practical operating experience and review the HAZOP report.

2. During Operation: Regular Re-Assessment Required

As per Document Anjian Zongguan [2013] No. 88, ongoing plants must continue periodic risk analysis after commissioning:

For “Two Key and One Major” installations → HAZOP at least once every 3 years

For other general installations → comprehensive risk analysis (which may include HAZOP, checklists, FMEA, etc.) at least every 5 years

This ensures that operational risks remain within acceptable limits as equipment, raw materials, or control systems evolve.

3. When Major Changes or Incidents Occur

HAZOP analysis should be repeated whenever major organizational or process changes take place, including:

Structural or staffing changes within the company

Modifications to equipment, process parameters, or control systems

Occurrence of a production safety accident or near-miss incident

These events may invalidate previous risk assessments, so regulators require a timely re-identification of hazards using HAZOP or equivalent techniques.

4. Integration with Safety Design and SIL Assessment

Recent guidelines such as Emergency [2022] No. 52 emphasize that HAZOP findings should directly feed into:

Safety facility design reviews

Safety Integrity Level (SIL) assessments

Pre-startup safety reviews (PSSR)

Each improvement suggestion raised during HAZOP must be tracked, assigned to responsible units, and closed before project completion.

5. Summary Table — When to Conduct HAZOP

| Scenario | Regulatory Reference | Stage | Frequency | Requirement |

|---|---|---|---|---|

| “Two Key and One Major” projects | AQ/T 3034-2022, 3033-2022 | Basic design | Once per project | Mandatory |

| First industrialization (new process) | Anjian Zongguan [2013] No. 76 | Basic design | Once per project | Mandatory |

| Major hazard installations | AQ/T 3034-2022 | Design & operation | Every 3 years | Mandatory |

| General production units | Anjian Zongguan [2013] No. 88 | Operation | Every 5 years | Recommended |

| Major organizational or equipment changes | Anjian Zongguan [2013] No. 88 | Any stage | As needed | Mandatory |

| After accidents or near misses | Same as above | Any stage | Immediate re-analysis | Mandatory |

6. Practical Tip: Embed HAZOP into Your Lifecycle Management

To stay compliant and maintain intrinsic safety, enterprises should integrate HAZOP into three critical checkpoints:

Design Verification – Conduct HAZOP during basic and detailed design.

Pre-Startup Review – Confirm all HAZOP recommendations are implemented before commissioning.

Periodic Review and Change Management – Revisit HAZOP when processes or people change.

This lifecycle approach not only ensures legal compliance but also minimizes process-related incidents and enhances overall reliability.

7. Final Thoughts

Many companies treat HAZOP as a one-time design exercise. In fact, it should be seen as a living process — revisited whenever the plant, people, or process change.

By institutionalizing regular HAZOP reviews, chemical enterprises can close regulatory gaps, protect personnel and assets, and build a culture of proactive safety.