In industrial process automation, not every plant requires advanced control strategies. In many cases, well-tuned PID loops and simple control logic implemented in the DCS are sufficient to achieve stable and efficient operation. However, for more complex processes, relying only on PID optimization can be inadequate, and advanced process control (APC) becomes necessary.

1. Cases Where PID Is Sufficient

Stable and simple processes: Clear cause–effect relationships, single variables, and minimal disturbances.

Low modification cost: DCS configuration and parameter tuning are enough to achieve automation.

Limited maintenance resources: Small, batch, or frequently modified units benefit more from simple PID control.

2. Scenarios That Require Advanced Control

2.1 Multivariable and Constraint-Driven Problems

Example: Blending operations

Several component oils must be blended at defined ratios and speeds, while simultaneously ensuring multiple product quality indicators (e.g., over ten regulated variables).

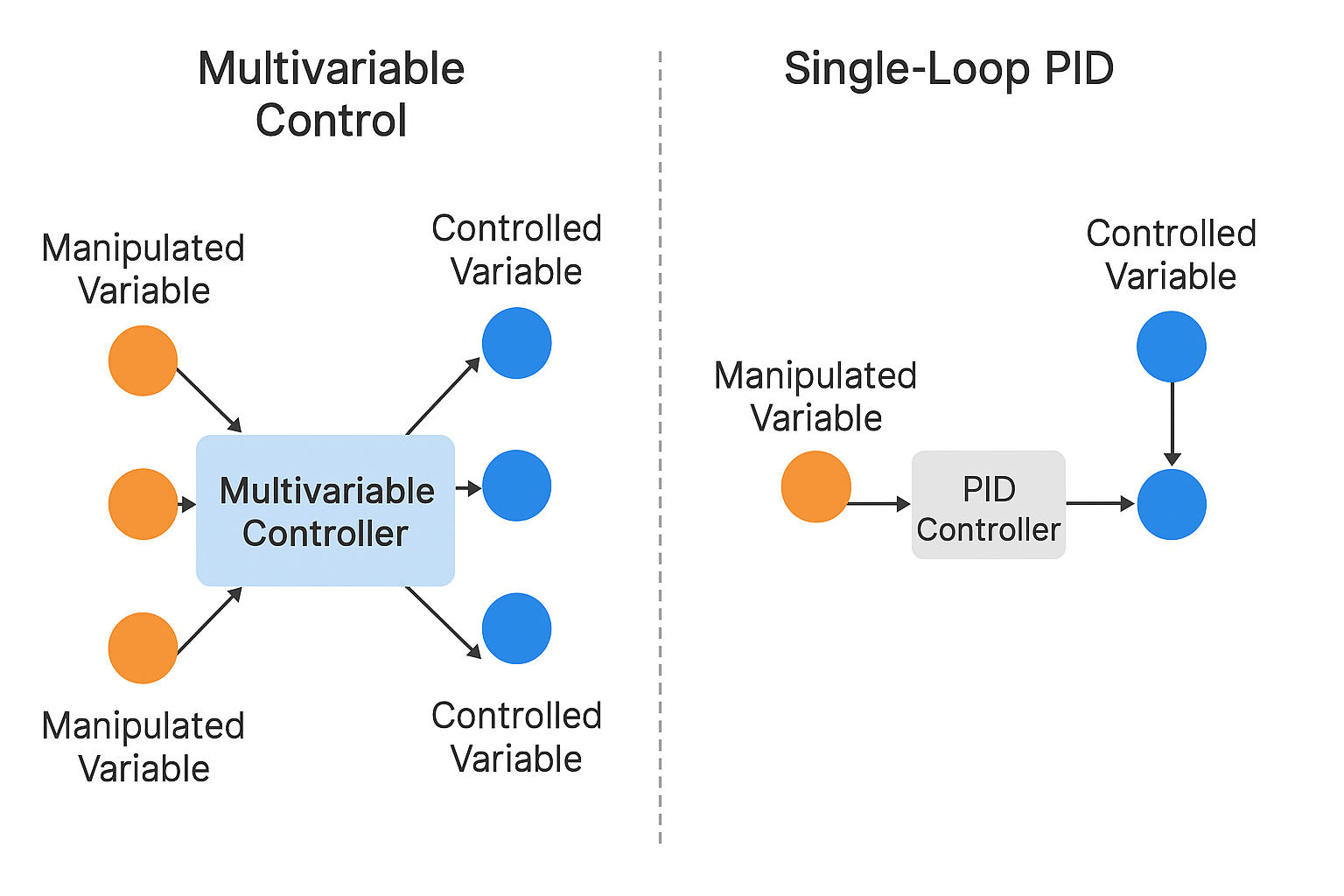

→ PID cannot effectively coordinate so many variables; multivariable control (MPC) is more suitable.

2.2 Complex Interacting Systems

Example: Tank farms with series/parallel liquid level systems

Single-loop level control is possible, but when process conditions are complicated, APC can maximize overall system performance.Example: Furnace branch outlet temperature balance

With PID in DCS, balancing branch temperatures is complex and rigid. APC can directly control branch temperatures as variables, achieving balance even if one branch fails.

2.3 Operating Condition Changes and Control Switching

In some processes, control authority must shift depending on conditions.

Example: Two manipulated variables control load and concentration (2×2 problem). If one variable saturates, control should automatically switch to the other for priority variables.

→ Implementing this with PID is complicated; APC handles it smoothly.

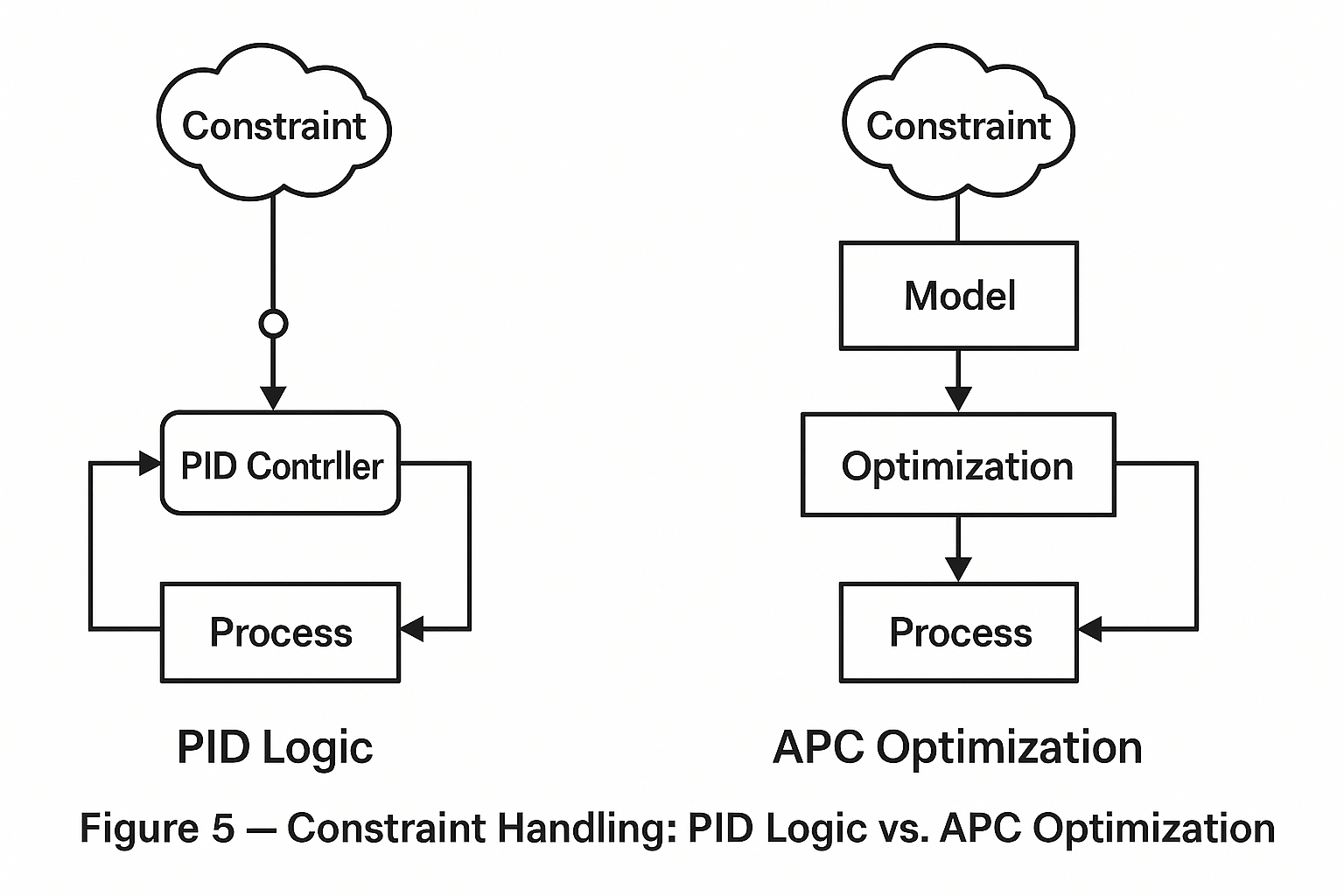

2.4 Optimization with Safety and Economic Constraints

When control must simultaneously ensure safety, stay within variable ranges, and pursue economic optimization, PID schemes become excessively complex.

APC incorporates constraints and optimization objectives natively.

2.5 Processes Difficult to Represent with PID Logic

Flotation circuits: Multiple rougher cell levels must coordinate with pump sump levels, while accounting for froth dynamics.

Solvent circulation systems: Tank buffering requires simultaneous control of multiple levels.

→ PID tuning is cumbersome, APC is more efficient.

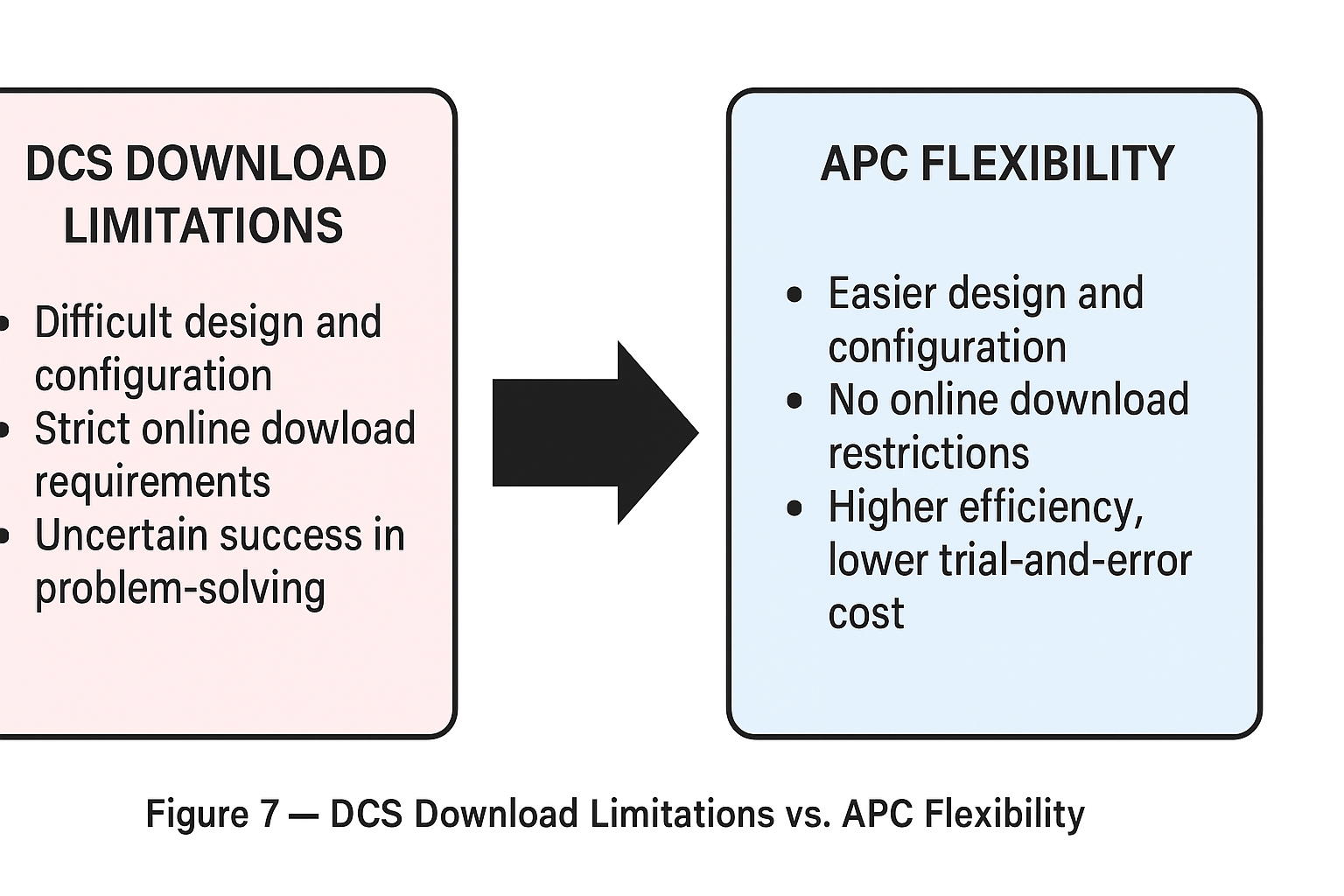

2.6 DCS Configuration Limitations

Some plants do not allow online DCS downloads, or the configuration workflow is too strict.

When the feasibility of a control solution is uncertain, APC can reduce trial-and-error costs by providing a more flexible test environment.

3. Common Misuses of APC

Applying APC where PID is enough: Adds unnecessary cost and complexity.

Using APC but only replicating PID functions: Wastes potential and weakens confidence in APC.

Correct deployment is critical: APC must be applied where its benefits clearly outweigh its cost.

4. Conclusion

PID control: Best for simple, stable, single-variable loops.

APC: Best for complex, multivariable, constraint-driven, or frequently changing processes.

Using APC in the right place maximizes plant efficiency, improves reliability, and supports both safety and profitability.