Stainless steels are indispensable in various industrial applications due to their corrosion resistance, durability, and strength. Among them, 304 and 321 stainless steel are both part of the austenitic family and often used in similar environments—but they are not interchangeable.

This article compares the chemical composition, temperature resistance, mechanical properties, and applications of 304 vs. 321 stainless steel, helping engineers and procurement specialists select the most appropriate material for their specific needs.

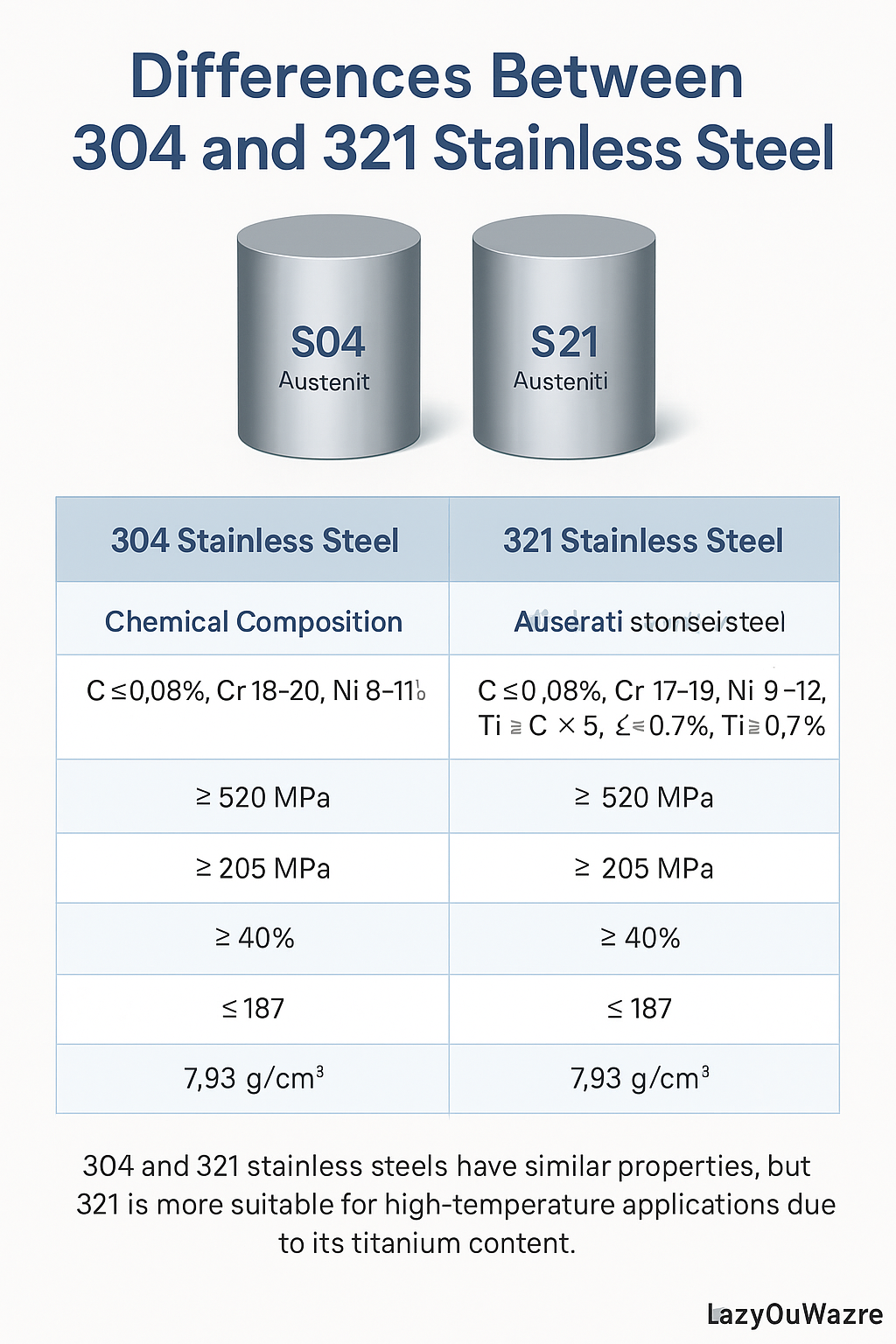

1. Chemical Composition

| Element | 304 SS (%) | 321 SS (%) |

|---|---|---|

| Chromium | 18.0 – 20.0 | 17.0 – 19.0 |

| Nickel | 8.0 – 10.5 | 9.0 – 12.0 |

| Carbon | ≤ 0.08 | ≤ 0.08 |

| Titanium | Not present | ≥ 5 × (C%) to ≤ 0.70% (typically ~0.3%) |

Key Point: 321 stainless steel is essentially 304 with the addition of titanium, which stabilizes it against chromium carbide formation.

2. Temperature Resistance

| Property | 304 Stainless Steel | 321 Stainless Steel |

|---|---|---|

| Maximum Continuous Use Temp | ~870°C | ~925°C |

| Thermal Stability | Moderate | High (improved resistance to intergranular corrosion) |

321 SS is superior in high-temperature environments (above 800°C), where 304 is prone to sensitization—a phenomenon that leads to corrosion at grain boundaries due to chromium carbide precipitation.

3. Mechanical and Corrosion Properties

| Property | 304 SS | 321 SS |

|---|---|---|

| Tensile Strength | ~515 MPa | ~505 MPa |

| Elongation | ≥ 40% | ≥ 40% |

| Corrosion Resistance | Excellent in most environments | Similar to 304, but better at high temps |

Note: In low to moderate temperature environments, both grades show similar corrosion resistance. The advantage of 321 becomes evident when thermal cycling or long-term heat exposure is involved.

4. Applications Comparison

| Application | 304 Stainless Steel | 321 Stainless Steel |

|---|---|---|

| Food Processing Equipment | ✓ | ✓ (less common) |

| Chemical Containers | ✓ | ✓ |

| Heat Exchangers / Boilers | ✗ (limited by temp) | ✓ |

| Jet Engine Parts / Exhausts | ✗ | ✓ (preferred) |

| Welding Environments | ✓ | ✓ (preferred if post-weld heat is high) |

5. Conclusion

While 304 stainless steel remains the industry standard for general-purpose corrosion resistance, 321 stainless steel offers enhanced performance in high-temperature and thermal cycling conditions due to its titanium content.

If your application involves prolonged exposure to elevated temperatures or welding, 321 SS is the better choice to avoid corrosion issues such as sensitization.