1. The working theory is different

Electromagnetic flowmeter working theory

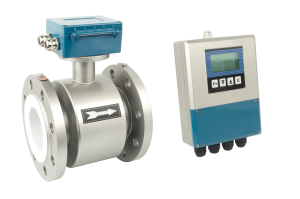

The electromagnetic flowmeter is a flowmeter that performs flow measurements according to Faraday’s law of electromagnetic induction. The advantage of the electromagnetic flowmeter is that the pressure loss is extremely small and the measurable flow range is large.

The ratio of the maximum flow rate to the minimum flow rate is generally above 40:1.

The applicable industrial pipe diameter range is wide, up to 3m. The output signal is linear with the measured flow rate, and the accuracy is high.

It can measure the conductivity ≥5μs/cm Fluid flow of acid, alkali, salt solution, water, sewage, corrosive liquid and mud, mineral pulp, paper pulp, etc. But it cannot measure the flow of gas, steam, and pure water.

When a conductor cuts the lines of force in a magnetic field, an induced electric potential will be generated in the conductor. The magnitude of the induced electric potential is proportional to the effective length of the conductor in the magnetic field and the speed at which the conductor moves in the magnetic field perpendicular to the direction of the magnetic field.

In the same way, when the conductive fluid flows in the vertical direction in the magnetic field and cuts the magnetic induction force lines, it will also generate an induced electric potential on the electrodes on both sides of the pipe.

Mass flow meter working theory

The mass flow meter adopts the heat-sensitive measurement to measure the flow rate by the molecular mass taken away by the split molecules. Because the heat-sensitive measurement is used, the gas temperature and pressure changes will not affect the measurement result. The mass flow meter is a relatively accurate, fast, reliable, efficient, stable, and flexible flow measurement instrument, which will be more widely used in petroleum processing, the chemical industry, and other fields. It is believed that it will show great potential in promoting flow measurement.

The mass flow meter cannot control the flow, it can only detect the mass flow of liquid or gas, and output the flow value through analog voltage, current or serial communication. However, the mass flow controller is an instrument that can detect and control at the same time.

In addition to the measurement part, the mass flow controller itself also has an electromagnetic regulating valve or piezoelectric valve, so the mass flow control itself constitutes a closed-loop system for controlling the mass flow of the fluid. The set value of the mass flow controller can be provided by an analog voltage, analog current, or computer or PLC.

2. The difference in the selection guide of the electromagnetic flowmeter and mass flowmeter

Selection principle of electromagnetic flowmeter

1). Accuracy class and function

Choose the accuracy of the electromagnetic flowmeter according to measurement requirements and use occasions. For example, for trade settlement, product handover, and energy metering, high precision should be selected (for example, 1.0 grade, 0.5 grade or higher)

2). Test medium flow rate, meter range, and diameter

When measuring general media, the full-scale flow of the electromagnetic flowmeter can be measured in a wide range of medium flow velocity 0.5-12m/s. The gauge size (caliber) selected may not be the same as that of the processing pipeline and should be determined according to whether the measuring flow range is within the flow rate range.

That is, when the pipeline flow rate is low and cannot meet the requirements of the flow meter, it is necessary to reduce the meter caliber, thereby increasing the flow rate in the tube and obtaining satisfactory measurement results.

Measure the liquid with good conductivity, the maximum flow velocity does not exceed 5m/s, the economic flow velocity range is 1.5m/s~3m/s

3). Electrode material and ground ring material

The corrosion resistance of the electrode to the measuring medium determines which electrode material to choose, and at the same time, the electrical level must not have surface effects. In other words, the corrosion resistance of the electrode is an important basis for selecting materials.

The material of the grounding ring should be the same as that of the electrode, otherwise, it is easy to produce electrochemical polarization potential. Generally, 316L or Hastelloy is used, but tantalum, platinum, and other precious metals are rarely used from economic considerations.

The metal process pipeline is in direct contact with the medium, and the grounding wire is directly connected to the metal pipeline or flange, so there is no need for a grounding ring

Selection principle of mass flow meter

1). Select the structure of the flowmeter according to the type of fluid being measured

There are many methods for the measuring tube of the Coriolis mass flowmeter, which need to be considered based on the type of medium to be measured.

In principle, pure liquids with low viscosity do not have many requirements for the shape of the measuring tube; when measuring liquids with a few bubbles, slurries containing solid particles, and high-viscosity liquids, the measuring tube should be selected that is not easy to accumulate bubbles or solid particles, and the inner wall The shape that is not easy to adhere to the medium; if used in the food industry, the measuring tube should be easy to clean

2). Security guidelines

When measuring corrosive fluids, attention should be paid to the corrosion resistance of the measuring tube, and the sensor housing should also have certain corrosion resistance.

If the detection tube breaks, there should be safety protection measures before handling it. Different media have different corrosivity, and different materials have different anti-corrosion targets, so pay attention to different treatments. When measuring abrasive media, the wear resistance of the measuring tube should be considered

3). Flow rate scale

Considering the flow scale, two criteria should be followed: one is because the Coriolis mass flowmeter has a greater impact on the accuracy of the lower limit flow measurement due to its zero point stability, Second, the commonly used process flow should fall within the economic flow scale of the flowmeter

4). Accuracy

The accuracy level requirements should be confirmed based on the measurement objectives and intentions. At the same time, attention should be paid to the calculation method of the product accuracy level and the operating conditions or constraints to reach the level. Generally speaking, the Coriolis mass flowmeter uses the percentage of the flow reading with zero-point stability to indicate the accuracy level. Some products use different flow sections corresponding to different error limits to show that some products are at low flow rates. Use the percentage of the full scale to indicate the error level.

5). Pressure loss

In infield measurement, there are always certain requirements for the pressure loss of the flowmeter. When the density, viscosity, and flow rate of the medium are confirmed, the pressure loss of the flowmeter depends on its structure.

For Coriolis mass flowmeters, it depends on the caliber, flow area, and measuring tube shape; when the sensor structure is confirmed, The greater the flow, the greater the pressure loss.

When calculating the pressure loss in the selection, the following points should be fully considered: the flow rate in the processing pipeline and the allowed pressure loss; whether the sensor meets the requirements of measurement accuracy under the allowed pressure loss condition; the change in the viscosity and density of the process fluid The influence of pressure loss; in the application, the liquid should be prevented from vaporizing due to excessive pressure loss.

When other conditions are combined, a flowmeter with less pressure loss should be selected.

6). Consideration of other functional elements

The first is to consider the additional measurement functions of the flowmeter, such as the accuracy of the Coriolis mass flowmeter to measure the temperature and density of the medium; the second is to consider the factors that affect the device such as the volume and weight of the mass flowmeter and the constraints of the dedicated cable.

3. The advantages of the electromagnetic flowmeter and mass flowmeter

The main advantages of electromagnetic flowmeter

- The output of the electromagnetic flowmeter is only proportional to the average flow velocity of the measured medium and has nothing to do with the flow state (laminar or turbulent) under a symmetrical distribution. Therefore, the electromagnetic flowmeter has a very wide range, with a range ratio of up to 20:1, and some even up to 100:1.

- The diameter range of industrial electromagnetic flowmeters is extremely wide, from several millimeters to several meters, and there is real-flow calibration equipment with a diameter of 3m in China, which has laid the foundation for the application and development of electromagnetic flowmeters.

- The sensor structure of the electromagnetic flowmeter is simple, and there are no moving parts in the measuring tube, nor any throttling parts that hinder fluid flow. Therefore, when the fluid passes through the flow meter, it will not cause any additional pressure loss. It is one of the flow meters with the lowest energy consumption in the flow meter.

- The electromagnetic flowmeter has no mechanical inertia and is sensitive. It can measure the instantaneous pulsating flow rate and the flow rate in both positive and negative directions.

- It can measure the flow of dirty media, corrosive media, and suspended liquid-solid two-phase flow. This is because there are no parts obstructing the flow inside the measuring tube of the instrument, and only the inner liner and electrode of the measuring tube are in contact with the measured fluid. The material can be selected according to the nature of the measured fluid. For example, using polytetrafluoroethylene or polytetrafluoroethylene as the inner lining can measure various acids, alkalis, salts, and other corrosive media; using wear-resistant rubber as the inner lining is particularly suitable for measuring wear and tear with solid particles Larger liquid-solid two-phase flow such as mineral pulp and cement slurry, and various suspended liquids such as fibrous liquid and pulp.

- The electromagnetic flowmeter is a volume flow measuring instrument. During the measurement, it is not affected by the temperature, viscosity, density, and conductivity (in a certain range) of the measured medium. Therefore, the electromagnetic flowmeter can be used to measure the flow of other conductive liquids only after being calibrated by water.

Advantages of mass flowmeters

- The mass flow meter directly measures the mass flow of the fluid, and the current signal converted by the transmitter does not need to be squared;

- Long service life and low maintenance rate: The measuring body of the mass flowmeter is a U-shaped tube, and the two open ends of the U-shaped tube are fixed. Fluid flows in and out from this. There are no obstacles in the pipeline, no moving parts, and failure factors. Less, easy to install and maintain;

- Multi-function: The mass flowmeter can simultaneously measure multiple field variables such as flow, density, temperature, etc. The transmitter has two output signals that can be configured separately, which can be used to display the measured values of flow, density, temperature, etc. One mass flow meter can replace multiple measuring instruments;

- High precision: It can reach ±0.1 (zero points stability/actual flow)×100% for liquids, and ±0.5 (zero points stability/actual flow)×100% for gases, which are used in cracking furnace feed control The zero-point stability of the mass flowmeter is 2.18KG/H for CMF200M418NU, 2.18KG/H for CMF200M419NU and 6.80KG/H for CMF300M426NU;

- The damping time of the mass flow meter is adjustable;

- The mass flow meter has a strong loop self-diagnosis function, which is convenient for fault finding.

4. Installation and Maintenance

Mass Flow Meters:

Mass flow meters can be more complex to install due to their reliance on the Coriolis effect, which requires careful alignment and vibration isolation. However, once installed, they require minimal maintenance and provide reliable performance over a long lifespan.

Magnetic Flow Meters:

Magnetic flow meters are generally easier to install, as they do not require moving parts or complex alignment. They can be installed in a wide range of pipe sizes and configurations. Maintenance is relatively simple, but periodic cleaning of the electrodes and calibration are necessary to ensure long-term accuracy.

5. Cost Considerations

Mass Flow Meters:

Due to their advanced technology and high precision, mass flow meters are typically more expensive than magnetic flow meters. The initial investment is higher, but the long-term benefits of accuracy and reduced maintenance can offset the cost in certain applications.

Magnetic Flow Meters:

Magnetic flow meters are generally more cost-effective, especially for applications involving large volumes of conductive liquids. Their lower upfront cost and ease of installation make them an attractive option for many industries.

Conclusion

Both mass flow meters and magnetic flow meters play vital roles in industrial flow measurement, but their differences make them suitable for different applications. Mass flow meters offer unparalleled accuracy and versatility, making them ideal for precise mass flow measurements in various industries. On the other hand, magnetic flow meters provide reliable and cost-effective volumetric measurements for conductive liquids, making them a popular choice in water treatment, chemical processing, and other similar applications.

When selecting a flow meter, it is essential to consider the type of fluid being measured, the required accuracy, installation complexity, and budget. By understanding the differences between these two types of flow meters, you can make an informed decision that ensures optimal performance for your specific needs.