1. Different working principles

The electromagnetic flowmeter is a flowmeter that performs flow measurements according to Faraday’s law of electromagnetic induction. The advantage of the electromagnetic flowmeter is that the pressure loss is extremely small and the measurable flow range is large.

The ratio of the maximum flow rate to the minimum flow rate is generally above 40:1.

The applicable industrial pipe diameter range is wide, up to 3m. The output signal is linear with the measured flow rate, and the accuracy is high.

It can measure the conductivity ≥5μs/cm Fluid flow of acid, alkali, salt solution, water, sewage, corrosive liquid and mud, mineral pulp, paper pulp, etc. But it cannot measure the flow of gas, steam, and pure water.

When a conductor cuts the lines of force in a magnetic field, an induced electric potential will be generated in the conductor. The magnitude of the induced electric potential is proportional to the effective length of the conductor in the magnetic field and the speed at which the conductor moves in the magnetic field perpendicular to the direction of the magnetic field.

In the same way, when the conductive fluid flows in the vertical direction in the magnetic field and cuts the magnetic induction force lines, it will also generate an induced electric potential on the electrodes on both sides of the pipe.

How do you make a band play if it is an elastic one? Easy- just take it in your two hands, stretch it in front of your face about an inch away from your lips, and then blow on it. When the relationship between the tension in the rubber band and the air velocity is just right, the band will hum quite loudly.

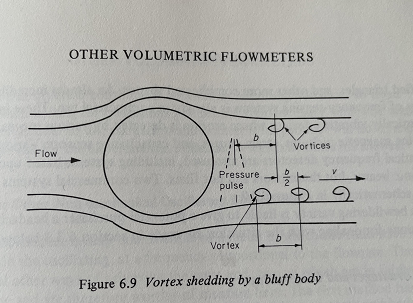

This happens because a succession of fluid vortices is emitted from the trailing edges of a body placed across a flowing stream(Figure 6.9). The only way to prevent this is by streamlining the body; conversely, the vortex effect can be enhanced by using what is known as a “bluff body”-that is, something shaped as awkwardly as possible, such as a prism whose cross-section is a rectangle or a triangle with its apex pointing downstream. As Figure 6.9 indicates, the vortices are emitted alternately from opposite sides of the obstruction with a distance b between adjacent vortices. In an ideal fluid their frequency, v/b, will be proportional to the fluid velocity. Associated with each vortex is what amounts to a pressure pulse, and so when the vortex frequency happens to equal the natural frequency of the obstruction it will resonate. Hence the noise emitted by your elastic band, whispering pines, and the Aeolian harp of the Greeks.

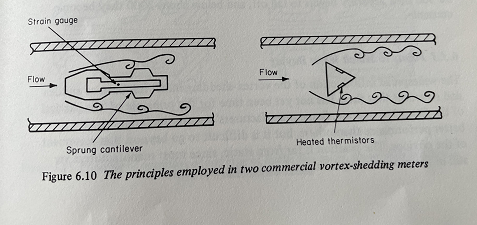

Within the past few years, a considerable number of flowmeters employing this principle have appeared on the market. They all consist of a spool of pipe containing a bluff-shaped rod lying across one diameter, and some means of sensing the frequency of vortex.

From there on, however, each manufacturer is on his own. They all seem to use different cross-sections for the bluff body, including a circle, rectangles, modified triangles, and other more complicated shapes. An almost incredible variety of frequency detectors are also used, including systems based upon ultrasonic beams, hot thermistors, and hot films. Two commercial systems are shown schematically in Figure 6.10.

2. The measurement medium is different:

electromagnetic flowmeter

The electromagnetic flowmeter can only measure the conductive liquid. But the bidirectional measurement meters, stability are very good, simple installation and maintenance-free.

Vortex flowmeter

The vortex flowmeter is widely used to measure superheated steam, saturated steam, compressed air, and general gases and liquids volume flow and mass flow.

3. the medium temperature is different:

Electromagnetic flowmeter

Electromagnetic flowmeter is the measurement of conductive liquid flowmeter, but the high temperature should not be used electromagnetic flowmeter.

Vortex Flowmeter

Relatively high practicality of the vortex, liquid gas can be measured, temperature into the scope is also relatively large, can measure high-temperature liquid and gas.

4. Advantages And Disadvantages is different

Electromagnetic Flow Meter Advantages And Disadvantages

Advantages of Electromagnetic Flow Meter

The following are the pros of the Electromagnetic Flow Meter

- Simple sensory structure: The electromagnetic Flow Meter consumes low amounts of energy. The meter has no moving fragments in the measuring tube. Also, it has no adjusting parts that obstruct the flow of the fluids flowing through it. Furthermore, no pressure is lost when fluid flow through the device.

- Accuracy: The electromagnetic Flow Meter device measures the suspended liquid-solid two-phase flow, sloping medium, and corrosive medium flows—the accuracy of these measurements attribute to the absence of obstructive flow components inside the measuring tubes. The flowing fluids get in contact with only the lining of the measuring tube and the electrode.

- Volumetric nature: The device is a volumetric measuring device. During the measurement process, the device is not affected by the measured medium’s density, viscosity, and temperature within a specific electrical conductivity range. Once calibrated by water, the gadget determines other conductive liquids’ flow rates.

Other advantages include:

- Ability to measure the reverse flow of liquids flowing through it

- Suitable for solid hydraulic transport

- Provides a wide linear range

- The measuring range setting has enhancements

Disadvantages of Electromagnetic Flow Meter

- Not suitable for measuring many fluids: The electromagnetic Flow Meter is designed to measure the liquid flow of a conductive medium. The device cannot be used to measure the flow of non-conductive media such as water and gas.

- Complicated commissioning and installation: The commissioning and installation of the Electromagnetic Flow Meter are more complex than other flow meters. Requirements for its installation are more rigorous. The converter and transmitter of the device must be used together and cannot be used in different instruments. The commissioning and installation must be done in strict accordance with the product’s specifications. During installation, one must ensure that the gadget is free from strong magnetic fields and vibrations. The piping and transmitter are in good contact and well-grounded during installation.

- Affected by dirt: when the electromagnetic glow meter is used to measure viscous liquids with dirt, the sticky sediments and substances stick to the inner linings or the tube’s electrode, causing a change in the output potential of the transmitter leading to an error in measurement.

- Changes in inner diameter size: The wear or scaling of the water supply pipe alters the size of the inner thickness, which affects the original flow value, and causes measurement errors. For instance, if the 100mm diameter meter’s inner diameter is altered by 1mm, it results in a 2% additional error.

- Not suitable for measuring fluids with high temperatures: The lining of the electromagnetic flow of the meter is affected by high temperatures that can result in changes in the diameter and flow of the fluids leading to an alternation in measurements.

- Not suitable for measuring liquids with low velocity.

Vortex flowmeter Advantages and disadvantages

Vortex meters are aimed at much the same section of the markets as orifice plates. The vortex has in general about the same moderate accuracy as the orifice plate(under favorable circumstances it can be more accurate), a similar head loss, and much the same sensitivity to upstream flow disturbances. As with the orifice plate, it is not necessary for every individual meter to be calibrated, since its flow characteristics can be predicted with reasonable accuracy. Like the orifice plate, it has no rotating mechanisms to wear or break down, and it can be designed to operate with both gases and liquids, either clean or dirty.

There the resemblance ceases. The vortex meter scores over the orifice plate by having a linear output, rather better repeatability, a much wider rangeability(10:1 is easily obtained and under favorable conditions, this can be greatly exceeded), and a direct digital output. Moreover, if the cost of the associated differential-pressure transducer is added to that of an orifice plate, the vortex can actually be cheaper than the orifice plate in sizes below about 200mm diameter. As the size increases, however, the vortex becomes progressively less competitive in price. Also, because the K-factor of vortex meters is inversely proportional to D3, the pulse generation rate of large meters is so low that it is difficult to calibrate them accurately.

For vortex meters to give their optimum performance the flow must well into the turbulent range. At pipe Reynolds numbers below about 20 or 30 000 their accuracy begins to fall off, and below about 3000 they become unusable.