In modern industrial environments, instrumentation devices are frequently exposed to complex electromagnetic conditions. Radiated electromagnetic immunity, a key component of electromagnetic compatibility (EMC), refers to a device’s ability to operate correctly in the presence of external electromagnetic radiation. Ensuring strong immunity is essential for the stable and reliable performance of instruments under such conditions.

1. Understanding Electromagnetic Compatibility (EMC)

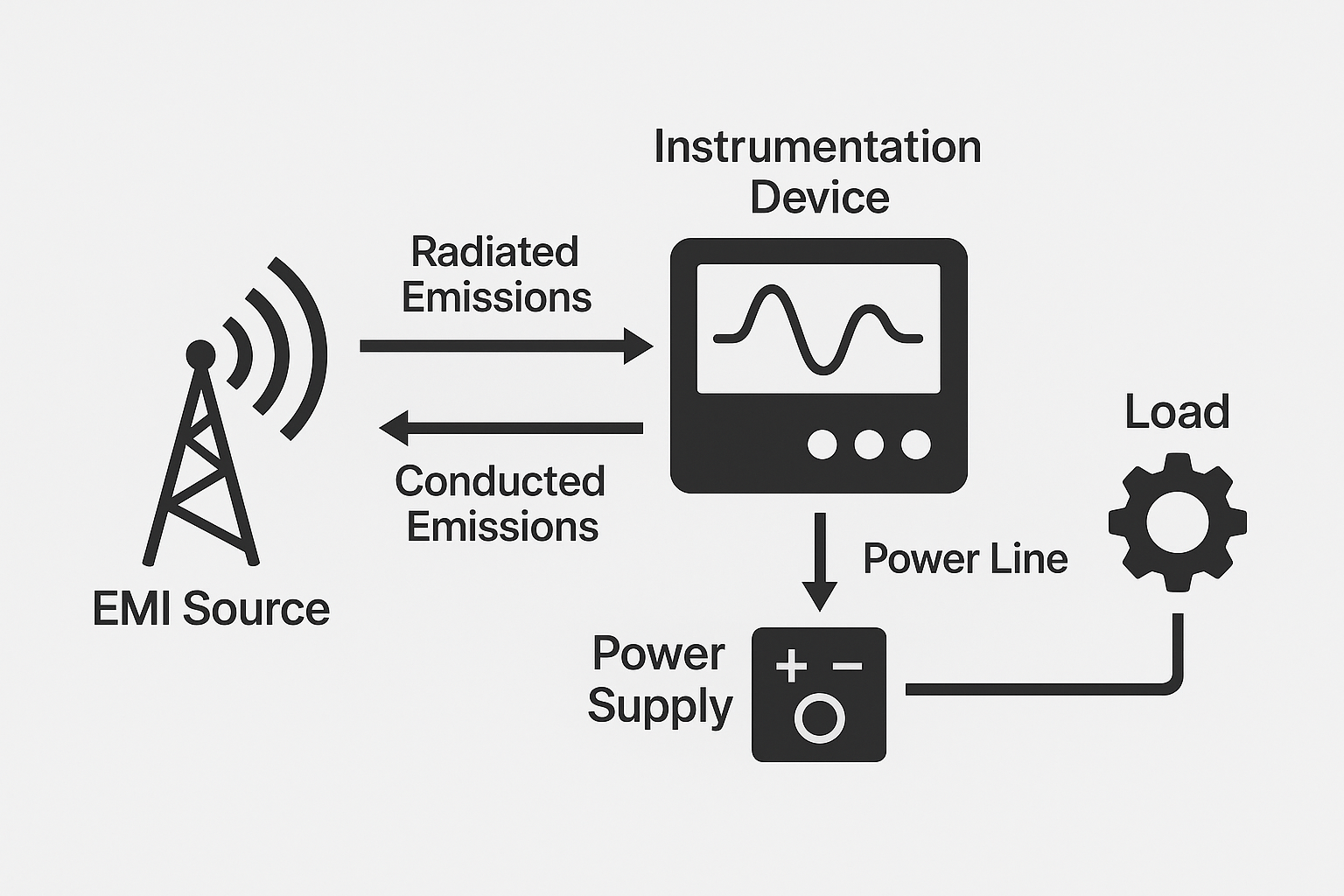

EMC describes a device’s capability to function properly within its electromagnetic environment, without causing or suffering from unacceptable electromagnetic interference. It consists of two main aspects:

Electromagnetic Interference (EMI):

The unwanted emission of electromagnetic energy from a device that may disrupt the function of nearby equipment.Electromagnetic Susceptibility (EMS):

The sensitivity of a device to external electromagnetic interference. A highly susceptible device may malfunction or degrade when exposed to interference.

2. Radiated Electromagnetic Immunity in Instruments

Radiated immunity is the instrument’s ability to resist external electromagnetic fields—such as radio waves, radar signals, or other radiated sources—and continue to operate as intended. It requires thoughtful design considerations to reduce electromagnetic susceptibility and improve operational stability.

Key Design Requirements:

Radiated Emission Limits:

The instrument must not emit excessive electromagnetic radiation that could interfere with other devices. Shielding and filtering techniques help maintain emissions within acceptable levels.Radiated Immunity Capability:

The instrument should withstand environmental electromagnetic fields without performance degradation. This is achieved through:Enhanced shielding design

Optimized PCB layout

Selection of low-susceptibility components

Proper grounding and filtering solutions

3. EMC Testing and Compliance

Evaluating an instrument’s radiated immunity is a crucial part of EMC validation. Testing involves exposing the device to simulated radiated environments and assessing its response under different frequencies and field strengths.

Common EMC Tests Include:

Radiated Emission Test:

Measures the electromagnetic radiation emitted by the device to ensure compliance with regulatory standards.Radiated Immunity Test (EMS):

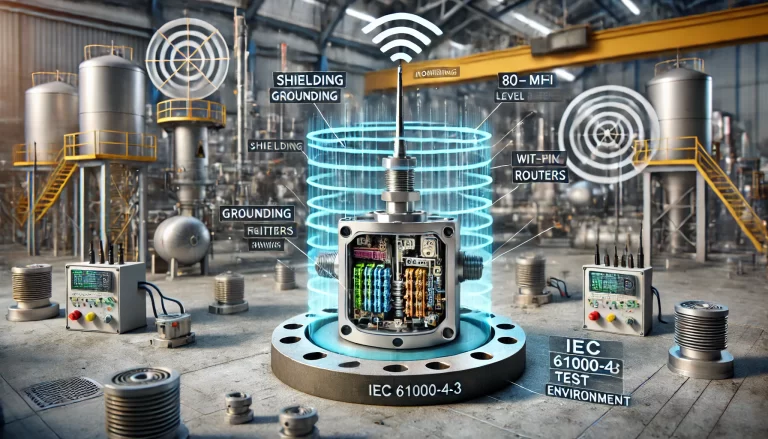

Simulates radiated interference (e.g., using an antenna emitting at 80–1000 MHz) to verify the device’s resilience under real-world conditions.

✅ Example:

Instruments tested under IEC 61000-4-3 and CISPR 11 standards can obtain CE marking, as in the case of vibrating rod level switches manufactured by Zero Instrument.

4. Importance of Improving Radiated Immunity

Enhancing radiated immunity is not just a technical requirement—it brings significant operational and commercial value:

✅ Operational Reliability:

Ensures accurate performance in high-interference environments such as factories, hospitals, and aviation systems.✅ User Safety:

Prevents critical equipment failures due to EMI, especially in applications like medical devices or safety interlocks.✅ Regulatory Compliance:

Helps meet EMC directives and certifications required for international markets (e.g., CE in the EU).✅ Market Competitiveness:

Products with robust EMC performance often stand out in the market as premium, reliable solutions.

5. How to Enhance Radiated Immunity in Instrumentation Devices

To improve radiated immunity, designers and manufacturers should consider:

🛡 Improved Shielding:

Use of shielding materials and enclosures to block incoming radiation.🔁 Optimized Circuit Layout:

Minimize loop areas and reduce coupling paths to lower susceptibility.🔌 Component Selection:

Choose components rated for low electromagnetic sensitivity.⚙️ Filtering & Isolation:

Integrate EMI filters, opto-isolators, and surge protection devices.🧪 EMC Pre-compliance Testing:

Conduct early-stage testing to identify vulnerabilities and meet IEC, EN, or GBT standards.

Conclusion

Radiated electromagnetic immunity is a vital aspect of instrument design, especially for industries demanding high reliability and precision. Through sound engineering practices and rigorous EMC testing, manufacturers can ensure compliance, improve product reputation, and build safer, more dependable industrial solutions.