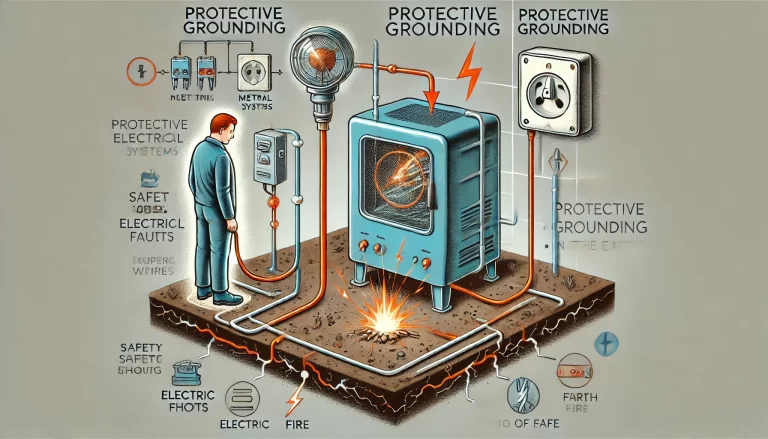

Protective grounding, also known as earthing, is a safety measure in electrical systems where the non-current-carrying metal parts of equipment (like the metal casing) are connected to the earth. This is done to protect both people and equipment in the event of an electrical fault.

The key purpose of protective grounding is to prevent high voltage from accumulating on the surface of equipment, reducing the risk of electric shock or damage.

Why is Protective Grounding Set Up?

Prevent Electric Shock: In the event of a fault, such as insulation failure inside the equipment, the outer casing may become energized. Without proper grounding, a person who touches the energized casing could receive a dangerous electric shock. Protective grounding ensures that the fault current safely flows to the earth, thus protecting the person from electric shock.

Improve System Safety: Protective grounding limits the voltage rise on the equipment’s surface in case of a fault, keeping it at a safe level. This adds an extra layer of safety for both the operators and the equipment itself.

Reduce the Risk of Fire Hazards: Electrical faults such as short circuits or current leakage can cause overheating or electrical arcs, which may lead to fires. Proper grounding channels the excess current safely into the ground, minimizing this risk.

Compliance with Electrical Codes and Standards: In most regions, protective grounding is required by law and is a standard practice in electrical engineering. It adheres to safety regulations, ensuring that installations meet local and international safety codes.

By setting up protective grounding, electrical systems become safer and more reliable, significantly reducing the risk of electric shock, equipment damage, and fire hazards.