Measurement testing, also known as metrology, is the science of measurement, which involves the process of determining the physical properties or parameters of an object or substance through a series of precise tests. In physics, this often refers to the use of specialized instruments to measure objects according to specific, standardized procedures. It includes activities like the calibration and verification of measurement instruments, ensuring they conform to national or international standards. This broad field encompasses a wide range of testing institutions, each providing measurements with varying degrees of accuracy depending on the application.

Metrology forms the backbone of modern society, functioning like an invisible ruler that measures the progress of human civilization. From everyday items like electronic scales and thermometers to complex industrial instruments and the high-precision measurements used in space exploration, measurement testing is embedded in the daily operations of our world.

1. Measurement Testing: The Guardian of Quality and Safety

In industrial manufacturing, measurement testing acts as a guardian of product quality. Take the automobile industry as an example. A modern car is made up of thousands of parts, each of which must meet specific dimensional and material performance standards. Precise measurement systems on production lines, such as those used by Volkswagen in Germany, can control deviations down to microns, ensuring that each vehicle meets rigorous quality standards before leaving the factory.

Similarly, in food safety, measurement testing is crucial for ensuring the safety of products consumed by the public. Additives, pesticide residues, and heavy metal content in food must be carefully tested using advanced measurement instruments. In China, food safety testing agencies utilize high-performance liquid chromatography (HPLC) systems capable of detecting harmful substances at the parts-per-billion level, providing a strong defense against unsafe food reaching consumers.

2. Measurement Testing: The Driver of Technological Innovation

The progress of measurement testing technology directly accelerates innovation across various scientific and industrial fields. In the semiconductor industry, for example, the production of microchips has entered the era of nanotechnology. Achieving 7nm and 5nm manufacturing processes requires extraordinary precision in measurement. ASML, a Dutch company, manufactures extreme ultraviolet (EUV) lithography machines, which measure at the atomic level. These advancements are pivotal in the global semiconductor revolution, enabling the production of faster, more powerful chips for electronics and computing.

In the aerospace industry, measurement testing plays an even more critical role. Components for spacecraft and satellites must be fabricated with extremely tight tolerances, as even the smallest error could result in mission failure. NASA employs advanced laser tracking measurement systems to ensure high-precision measurements of large components, ensuring the safety and reliability of their spacecraft.

3. Measurement Testing: The Catalyst for Industry Upgrades

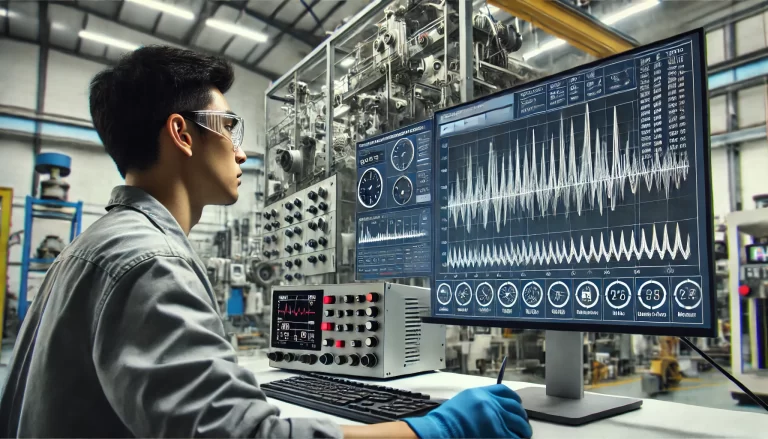

With the advent of Industry 4.0, measurement testing is rapidly evolving towards intelligent and networked systems. In smart factories, online measurement testing systems monitor production parameters in real-time, enabling automated quality control. Siemens, for example, has integrated measurement testing technologies into its digital factories, connecting them via the Internet of Things (IoT). This connectivity allows for seamless data flow and full traceability of the manufacturing process, ensuring high levels of precision and quality in production.

Furthermore, in emerging fields such as 5G telecommunications and artificial intelligence, the role of measurement testing is indispensable. For instance, 5G base stations require precise phase measurements for antenna arrays, while AI algorithms demand highly accurate data labeling during training. Huawei has adopted automated testing systems for its 5G base station production lines, significantly enhancing testing efficiency by up to 300%.

4. The Future of Measurement Testing

As we move towards an increasingly digital and interconnected world, the role of measurement testing will only grow in importance. With advancements in artificial intelligence, big data, and quantum computing, the need for highly accurate and reliable measurement systems will be crucial in exploring new frontiers in science and technology. Whether in the development of self-driving cars, medical technologies, or sustainable energy systems, measurement testing will remain a foundational pillar supporting the progress of industries and societies alike.

Conclusion

Measurement testing is the cornerstone of modern industrial civilization, ensuring the accuracy, safety, and reliability of products and systems across all sectors. As technology advances, the capabilities of measurement systems will continue to break new boundaries, offering unprecedented levels of precision. In the coming smart era, metrology will play an even more critical role in shaping the future of human society, driving us toward new scientific discoveries and more efficient, sustainable industries.