Many people think “aging” happens only after several years of use. In reality, the aging of polymer materials begins the moment they are formed.

Engineers often encounter:

Yellowing or discoloration

Loss of mechanical strength

Surface roughening or cracking

Electrical performance drifting

Mold or surface contamination

These are not simply “process issues.” They are manifestations of the material seeking a more stable state over time.

1. Aging Starts at Birth

Polymers are non-equilibrium systems.

Within their structure, strong and weak bonds coexist; some chain segments are mobile, while others are constrained. Under the influence of heat, oxygen, UV light, moisture, and mechanical stress, molecular chains undergo:

Rearrangement

Scission (chain breaking)

Oxidation

Cross-linking

In other words:

Aging is the natural process of a material gradually moving toward a more stable energy state.

What we observe externally (yellowing, embrittlement, micro-cracks) is simply the visible outcome of internal chemical changes.

Aging is unavoidable. What we can do is delay it and control it.

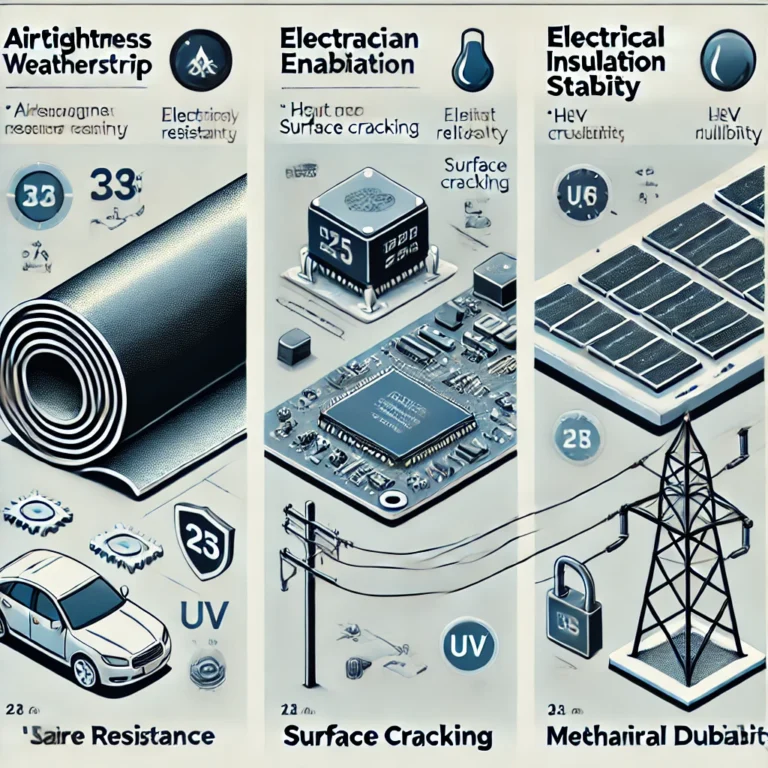

2. Define Aging Criteria Based on Real Use Conditions

Different applications have different failure thresholds:

| Application | Key Aging Indicators |

|---|---|

| Automotive weatherstrips | Airtightness, elongation, surface cracking |

| Semiconductor encapsulation | Electrical insulation stability, reliability under heat |

| Outdoor power cables | UV resistance, long-term mechanical durability |

Do not copy others’ aging criteria directly.

Your aging evaluation should be based on:

Material characteristics

Customer performance requirements

Actual operating environment

3. Why Aging Validation Is Essential

Some newcomers ask: “The material works fine now. Why test aging?”

Because aging validation is risk control.

Scientific Perspective

Polymers are inherently unstable against environmental energy input. Accelerated aging tests allow us to observe years of degradation within weeks or months.

Engineering Perspective (Three Objectives)

Predict Service Life

Build performance–time decay curves and estimate usable lifetime.Select Formulation and Process

Stabilizers, antioxidants, and fillers may perform similarly at room temperature but differ significantly under aging stress.Ensure Environmental Adaptation

Different climates (UV, humidity, temperature) can lead to drastically different aging behaviors.

Aging validation is not about proving the material will fail, but about understanding how, when, and why it may fail.

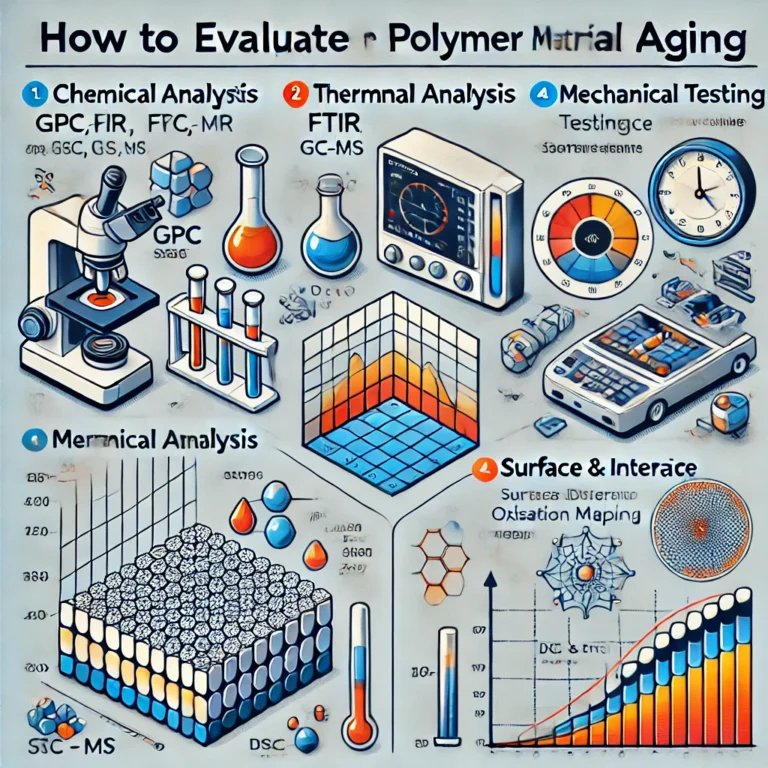

4. How to Evaluate Aging

A reliable evaluation combines chemical, thermal, mechanical, and surface/interface monitoring:

Chemical Analysis

GPC: Molecular weight change (chain scission vs. cross-linking)

FTIR: Oxidation / hydrolysis signals (carbonyl, hydroxyl groups)

GC-MS: Detection of degradation byproducts or volatile components

Thermal Analysis

DSC: Glass transition temperature (Tg), crystallinity shift

Mechanical Testing

Tensile strength, elongation, modulus

Fatigue and creep for long-term load conditions

Surface & Interface

Color difference ΔE

Micro-cracks (SEM / optical surface imaging)

Surface oxidation (XPS / FTIR mapping)

Electrical / Optical (when applicable)

Volume resistivity, breakdown strength

Transmittance and haze (films)

Single data points are not reliable. Trends over time tell the true story.

5. Accelerated Aging Must Match Real Mechanisms

We accelerate aging because no one can wait 3–10 years.

Common methods include:

Thermal aging (Arrhenius acceleration)

UV weathering

Damp–heat cycling

Mechanical stress cycling

However:

If the acceleration mechanism differs from the real service mechanism, the result will be misleading.

Correct approach:

Use accelerated tests to screen and compare

Calibrate lifetime predictions using limited real-environment exposure data

6. Engineering Strategies to Extend Service Life

Chemical Stabilization

Antioxidants, UV absorbers, light stabilizers, hydrolysis inhibitors.Barrier / Protection

Coatings, carbon black for UV shielding, moisture barriers.Structural Design

Add mechanical safety margin, avoid sharp stress concentration areas.Process Control

Reduce residual stress, ensure proper drying, curing, and molding stability.Maintenance & Monitoring

Periodic inspection or sensing-based condition monitoring for critical components.

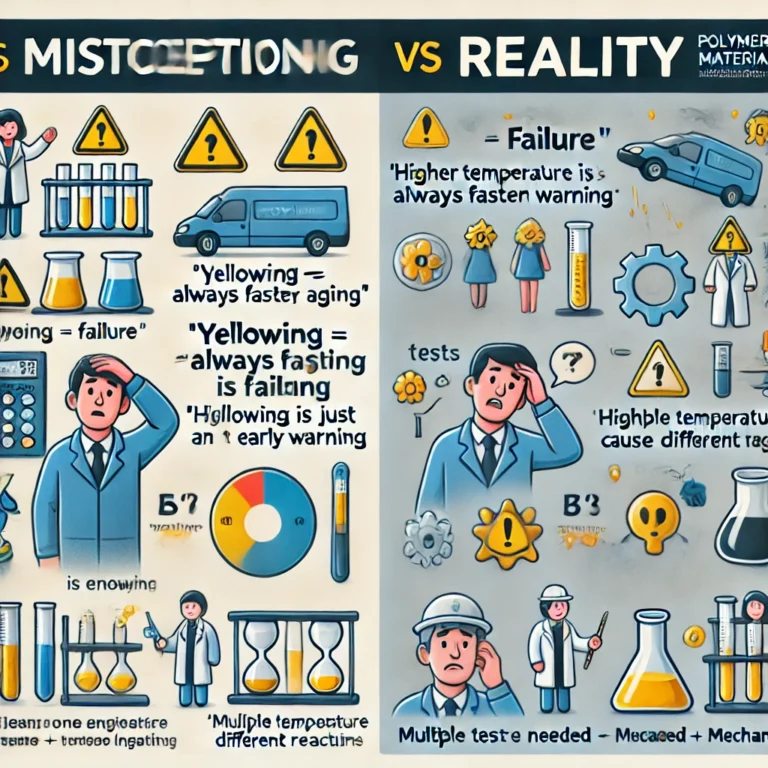

7. Common Pitfalls to Avoid

| Misconception | Reality |

|---|---|

| Surface yellowing = material failure | Not always. Treat as an early warning, not final failure. |

| Higher temperature = faster aging (always) | Wrong. May induce a different reaction pathway. |

| Testing only one indicator is enough | No. Chemical + thermal + mechanical must be combined. |

8. A Proactive Approach to Reliability

Aging is not a flaw. It is an inherent property of polymer systems.

The key capability of an engineer is to make aging:

Measurable, predictable, and manageable.

When you can clearly state:

Under what conditions (X)

Which property (Y)

Will reach its limit at what time (Z)

You move from reactive troubleshooting to predictable reliability engineering.