Introduction

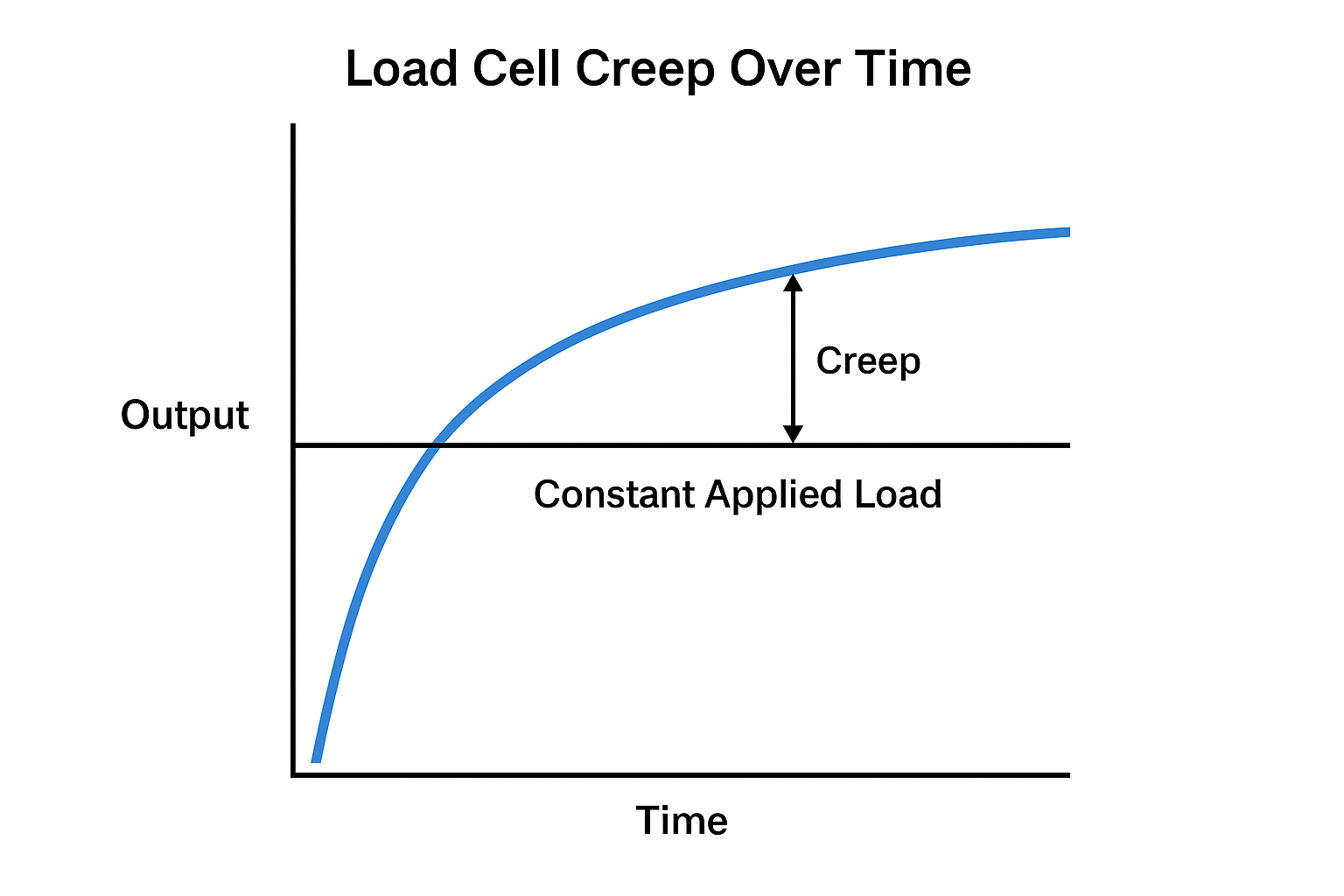

You may have noticed that when a constant load is placed on a weighing system, the reading slowly drifts over time—even though nothing changes physically.

This is not a failure or signal instability.

It’s called load cell creep—a natural behavior of strain-based transducers.

In this article, we explain what creep is, what causes it, how to minimize its impact, and why it matters in high-precision applications.

1. What Is Creep in Load Cells?

Creep refers to the slow, time-dependent change in a load cell’s output when a constant force is applied.

❝ Even though the applied weight doesn’t change, the output reading “creeps” up or down slightly over time. ❞

Typically measured over 20 or 30 minutes, this drift is a result of internal mechanical and material relaxation in the load cell structure.

2. What Causes Load Cell Creep?

Several factors contribute to creep:

⚙️ Elastic deformation of the strain body (metal structure relaxes under stress)

🌡️ Thermal effects: Temperature affects resistance and structure simultaneously

🧵 Strain gauge adhesive relaxation

⚡ Bridge imbalance in the Wheatstone circuit

🧊 Material hysteresis (non-linear mechanical return after loading)

3. Is Creep the Same as Drift?

No.

| Term | Description |

|---|---|

| Creep | Time-based change under constant load |

| Drift | Long-term change due to aging, temperature, etc. |

| Zero Drift | Output shift when no load is applied |

4. How Is Creep Specified in Datasheets?

Creep is usually listed like this:

Creep (30 min): ±0.03% F.S.

→ After 30 minutes at full load, output may change by ±0.03% of full scale.

Some datasheets also list:

Return to zero (creep recovery)

Creep after X minutes at Y% rated load

5. When Does Creep Matter Most?

Creep has minimal impact in dynamic or short-duration loads.

But in the following scenarios, it’s critical:

| Application | Why Creep Matters |

|---|---|

| Gravimetric dosing systems | Affects dosing accuracy over hold periods |

| Tanks/silos with slow fill | Reading shifts during batch |

| Legal-for-trade scales | Compliance requires tight creep tolerance |

| Scientific testing machines | Long-duration tests demand stable output |

6. How to Minimize Creep

✅ Choose Low-Creep Load Cells

Look for creep ≤ ±0.02% F.S. over 30 min

Some stainless steel sensors have better stability than aluminum

✅ Use Temperature-Compensated Sensors

Creep is often worse with thermal changes

✅ Apply Load Smoothly and Gradually

Sudden shock loading can worsen mechanical relaxation

✅ Wait for Stabilization Before Taking Readings

Some systems include a “settling delay” timer

✅ Consider Creep Correction Algorithms

High-end controllers or software can linearize and correct for creep over time

7. Creep vs Hysteresis vs Nonlinearity

| Effect | Description |

|---|---|

| Creep | Slow change in output under constant load |

| Hysteresis | Different output for loading vs unloading |

| Nonlinearity | Output curve deviates from a straight line |

All are critical in precision load cell performance, but creep is the most time-sensitive of the three.

Conclusion

Load cell creep is not a defect—it’s a material reality.

By understanding its behavior and planning for it in both hardware and software design, you can ensure consistent, reliable readings even in long-duration or compliance-sensitive applications.

Creep may be slow—but if you ignore it, the consequences might not be.