Abstract

In modern industrial production, automation instruments are key tools for process monitoring, control, and safety assurance. To ensure accurate identification, rational arrangement, and efficient management of numerous instruments, the industry widely adopts instrument tag numbers as a standardized method of identification.

This article explains the significance of tag numbers, common compilation rules, international standards, and practical application cases.

1. Importance of Instrument Tag Numbers

1.1 Unique Identification

Each instrument requires a unique “ID card”—its tag number. With tag numbers, operators and maintenance staff can quickly locate instruments within large-scale installations, minimizing errors.

1.2 Fault Location and Maintenance

During operation, if an anomaly occurs, maintenance teams can rely on tag numbers to rapidly identify and repair or replace the faulty instrument, reducing downtime and improving plant safety.

2. Information Transfer and Management

2.1 Engineering Design Phase

Tag numbers form the basis for P&ID (Piping and Instrumentation Diagrams).

They define each instrument’s function, location, measurement parameters, and relationships with other equipment.

2.2 Production and Operation Phase

Operators use tag numbers in DCS/PLC interfaces to monitor process parameters and make precise adjustments.

2.3 Maintenance and Historical Records

Tag numbers serve as key indexes in asset management systems, linking to equipment files, maintenance logs, and replacement records.

3. Standardization and Norms

3.1 Industry Standards

ISA 5.1 “Instrumentation Symbols and Identification”

China’s Chemical Process Control Design Code

These ensure cross-vendor compatibility, unified design practices, and better project execution.

3.2 Data Integration and Smart Manufacturing

In the context of Industry 4.0, standardized tag numbers enable data integration across systems (DCS, MES, ERP), supporting digital twins and advanced analytics.

4. Common Tag Number Compilation Rules

4.1 Basic Structure

Letter Codes (measured variable or function):

Temperature (T), Pressure (P), Flow (F), Level (L), Analysis (A)

Function Codes (instrument role):

Indicator (I), Recorder (R), Controller (C), Alarm (A)

Table 1 — Common Instrument Letter Codes and Functions

| Measured Variable / Function | Letter Code | Description |

|---|---|---|

| Temperature | T | For sensors, transmitters, and controllers measuring temperature |

| Pressure | P | For pressure-related instruments (gauge, transmitter, controller) |

| Flow | F | For flowmeters, flow indicators, and flow controllers |

| Level | L | For level transmitters, indicators, and controllers |

| Analysis (Chemical/Composition) | A | For analyzers such as pH, oxygen, or gas analyzers |

| Indicator | I | Device showing real-time measurement (local or panel display) |

| Recorder | R | Device recording measured values (chart, digital, or electronic) |

| Controller | C | Device controlling a variable automatically |

| Alarm | A | Device giving audible/visual alerts when exceeding limits |

| Transmitter | T (suffix) | Device transmitting a signal to a control system |

| Switch | S | Device switching ON/OFF state based on measurement |

| Relay / Interlock | L | Device linked to safety or process interlock logic |

4.2 Numbering Methods

Process Sequence Numbering: TI101, TI102 …

Equipment-Based Numbering: T-RF101 (temperature on reactor RF101)

Area-Based Numbering: A-101 (instrument no.101 in Area A)

4.3 Special Cases

Multivariable instruments: TPI601 (Temperature/Pressure Indicator)

Interlock instruments: PIL701 (Pressure Interlock Instrument)

5. Examples of Common Tags

Temperature Instruments: TI101 (Indicator), TR102 (Recorder), TC103 (Controller)

Pressure Instruments: PI201, PR202, PC203

Flow Instruments: FI301, FR302, FC303

Level Instruments: LI401, LR402, LC403

Analysis Instruments: AI501 (pH), AO502 (Oxygen content)

Multivariable: TPI601, FLI602

Interlock: PIL701, TIL702

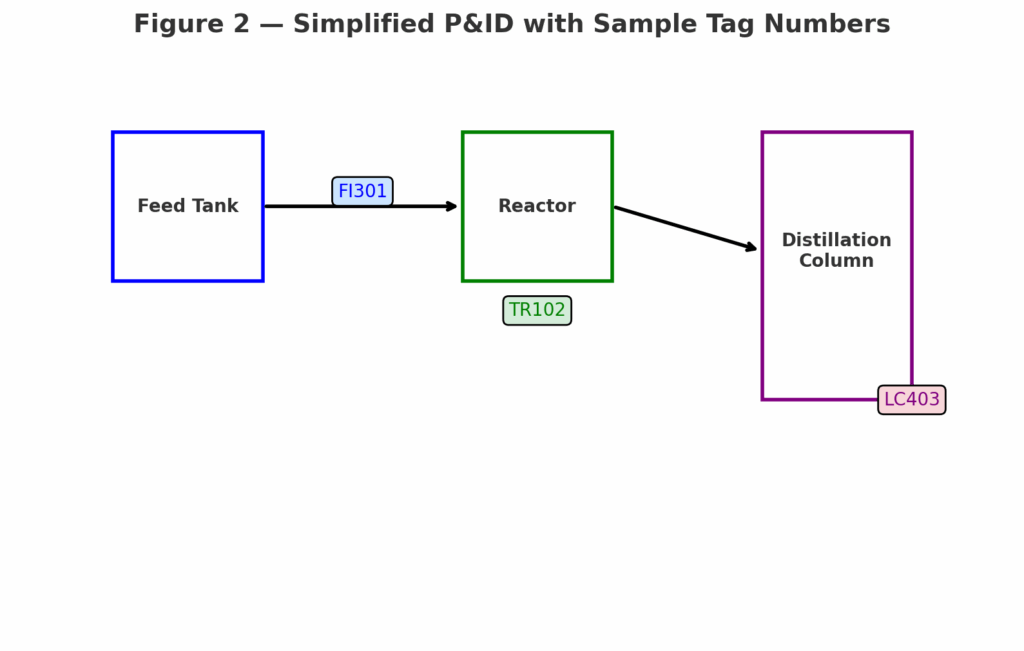

6. Practical Application Case

In a distillation unit of a chemical plant:

FI301 monitors feed flow.

TR102 records reactor temperature.

LC403 controls bottom level in the separation tower.

Operators can quickly trace alarms and take corrective actions through tag numbers.

7. Conclusion

Instrument tag numbers are more than a coding system—they are the management link that integrates identification, information transfer, lifecycle management, and data integration.

In the era of smart factories, well-structured and standardized tag numbers are essential to achieving safety, efficiency, and digital transformation.