An instrument air manifold is a pipeline component used to distribute instrument air to various devices. It takes clean air from a source (such as a compressor or air dryer) and distributes it across multiple branches to instruments that require compressed air.

It can be understood as the “distribution hub” for instrument air, similar to an electrical distribution box but for clean, stable compressed air.

Main Applications

The primary functions of an instrument air manifold include:

Air Distribution to Multiple Instruments or Devices:

Pneumatic valve actuators

Pneumatic control valves

Pneumatic instruments (transmitters, positioners)

Pneumatic instrument cabinets, analyzer shelters, filter regulators, etc.

Centralized Connection for Easy Management:

Typically installed in instrument galleries, equipment platforms, or near control rooms for easier maintenance and switching.

Branch Control and Isolation:

Each branch is equipped with:

Shut-off or Needle Valves: To open/close each branch.

Pressure Gauges: To monitor branch pressure.

Regulators/Filters (optional): To fine-tune the pressure for each branch. Some branches also feature quick-connects for maintenance and purging.

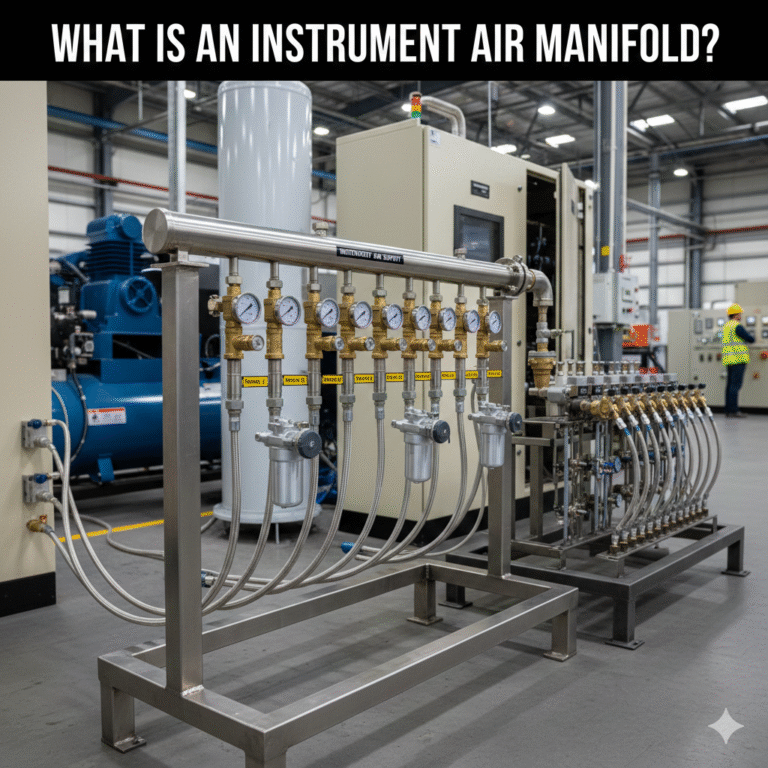

Components of an Instrument Air Manifold

A typical instrument air manifold consists of:

| Component | Function |

|---|---|

| Header | Connects to the main instrument air pipeline and serves as the source for air distribution. |

| Branch Connections | Distribute air to individual instruments, often with 4, 6, 8, or 12 branches. |

| Shut-off/Needle Valves | Control the flow or shut-off of each branch. |

| Pressure Gauges | Indicate the pressure on each branch. |

| Filter/Regulator (FR) | Ensure clean, stable air pressure (optional, depending on requirements). |

| Relief Valve or Plug | Used for venting or sealing unused ports. |

The manifold is often made from galvanized carbon steel, stainless steel, or copper alloy, selected based on gas quality and the specific application environment.

Why Do Factories Need Instrument Air Manifolds?

Instrument air must be:

Clean

Dry

Stable in pressure

Continuously supplied

However, with many air consumption points on-site, it’s impractical to run a direct line from the main pipeline to every point. Therefore, a centralized, controlled distribution point is needed.

Key Benefits of an Instrument Air Manifold:

Improved Reliability: Independent branches prevent interference between instruments.

Easier Maintenance: Allows isolation of individual branches for maintenance without affecting others.

Precise Pressure Management: Different instruments can be supplied with different air pressures.

Organized Layout: Helps keep the site neat and standardized.

Typical Workflow (Simplified)

Compressor → Dryer → Filter to produce instrument air.

Instrument air enters the manifold header.

The manifold distributes the air to various pneumatic devices.

Each branch can be individually controlled, regulated, and monitored.

In summary:

One main air line → enters manifold → splits into multiple stable, controllable branches → delivered to various instruments.

Common Installation Locations

Instrument air manifolds are typically installed in:

Support frames of instrument galleries

Equipment platforms in the plant area

Instrumentation areas in process units

Outside analyzer shelters or PLC cabinets

Air compressor station exit areas (primary distribution)

They are usually placed near air consumption points but should avoid areas with high temperatures, corrosive environments, or intense vibrations.

Difference Between “Instrument Air Manifold” and “Manifold Box”

Instrument Air Manifold: Refers to the pipe and valve components that distribute air.

Manifold Box (PFM): A casing that houses the manifold, typically used for outdoor installations to protect against rain and dust.

The manifold serves as the “heart,” while the box serves as the “shell.”

Visual Analogy

If you compare an instrument air system to a building’s water supply system:

Compressor → Water plant

Main instrument air line → Main water line

Instrument air manifold → Floor-level water distribution box

Branches → Individual household water pipes

It ensures each “air consumer” (instrument) has its own controllable inlet.

In Summary

An instrument air manifold is a crucial distribution component in industrial settings. It divides a single main air line into multiple branches that are independently controlled and regulated, serving as an essential node in a pneumatic instrument system.