1. Definition of Surge

A surge (also called a transient overvoltage/overcurrent) refers to a short-duration pulse that appears on power or signal lines.

Time scale: From nanoseconds to milliseconds.

Amplitude: Peak values often exceed more than twice the steady-state voltage/current.

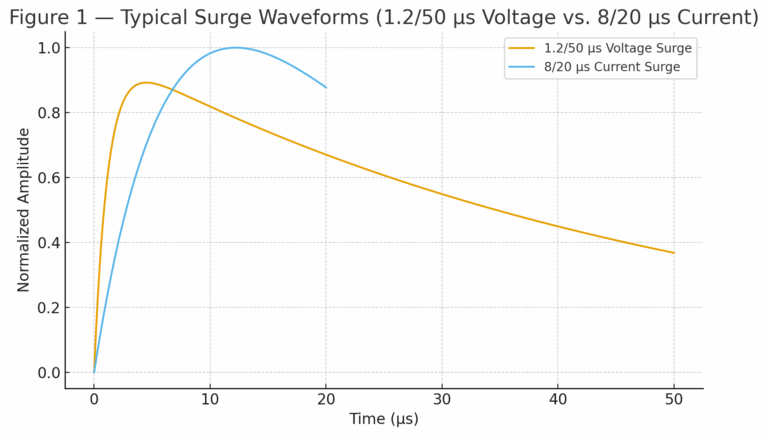

Waveform: Typical waveforms include 1.2/50 μs voltage waves and 8/20 μs current waves.

Essentially, a surge is a high-energy, fast-rising transient pulse that may be caused by lightning, power grid switching, or the starting and stopping of large loads. Without proper surge protection, these transient energies can directly damage electronic components, leading to equipment failure or system shutdown.

2. Sources of Surge

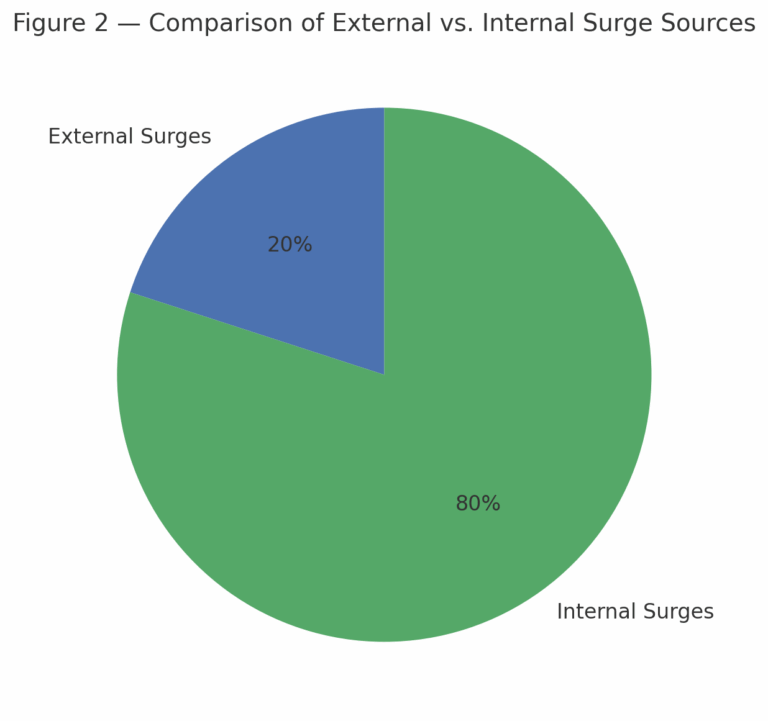

External surges (~20%)

Lightning strikes

Electromagnetic radiation

Ground potential rise

Internal surges (~80%)

Motor, pump, or compressor switching

Capacitor bank switching

Short-circuit faults

Mechanical switch contacts

Surges are not limited to thunderstorms; they occur in daily operations. This means that industrial instruments are exposed to surge threats almost every day.

3. Impact on Instrumentation

Instrumentation devices are highly vulnerable because they:

Use long cables that easily pick up transients.

Contain sensitive semiconductor components.

Types of impacts:

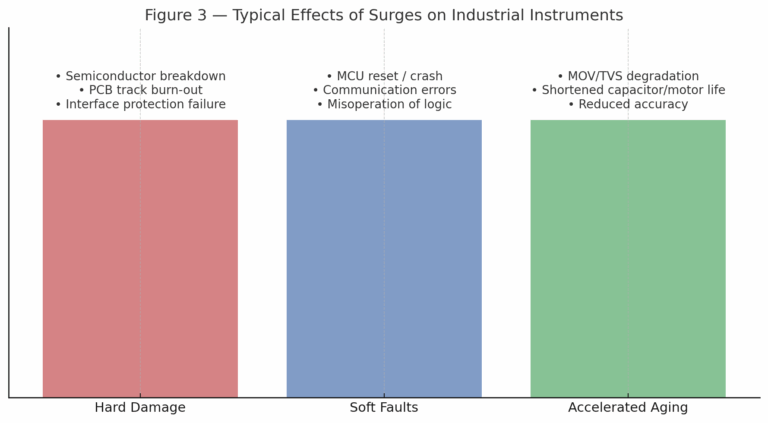

Destructive failure (hard damage)

Semiconductor breakdown

PCB track burn-out

Damaged interface protection components

→ Result: Total equipment failure, production downtime

Functional disturbances (soft faults)

MCU reset, system crash

Communication errors, data loss

Misoperation of control logic

→ Result: Process anomalies, safety risks

Accelerated aging

MOV/TVS degradation, increased leakage current

Capacitor and motor lifespan reduction

Decreased measurement accuracy

→ Result: Shorter service life, higher maintenance cost

4. Why Surge Protection is Essential

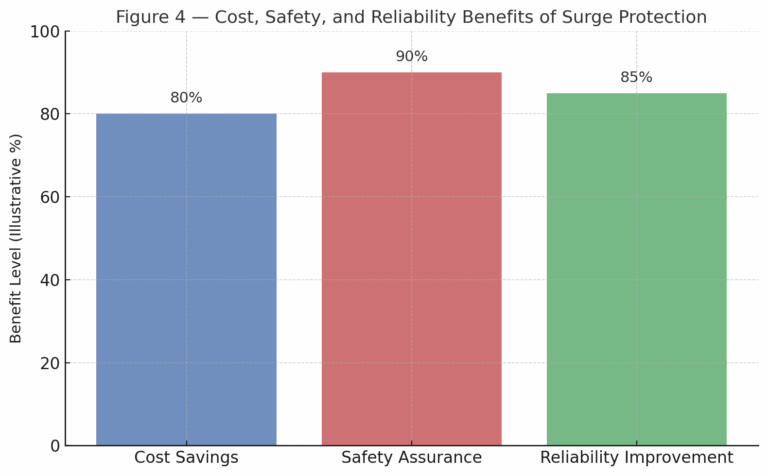

Economic aspect: A single surge may destroy modules worth thousands of dollars, with even higher downtime losses.

Safety aspect: In critical industries (chemicals, power, transportation), surges may cause false alarms or malfunctions, leading to major accidents.

Reliability aspect: Surge protection extends instrument lifespan, reduces maintenance, and ensures stable long-term operation.

Surge protection is not optional but a mandatory condition in the design and selection of industrial equipment.

5. Engineering Methods for Surge Protection

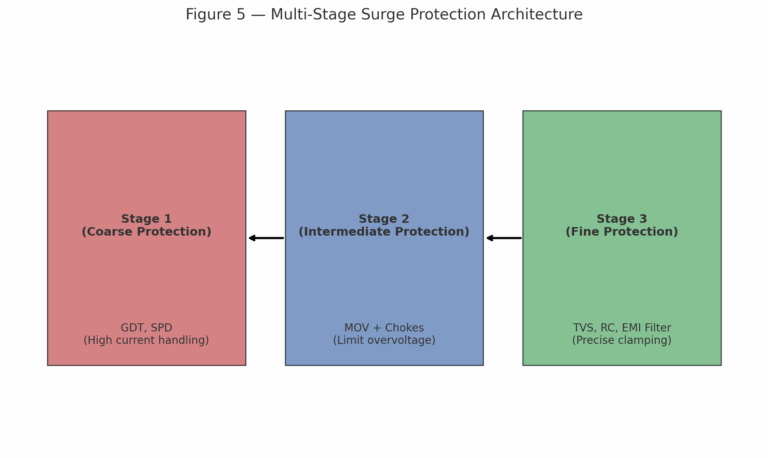

Effective protection follows the principle of layered, staged, and zoned defense:

Gradual energy dissipation

Voltage clamping

Filtering and waveform shaping

(1) Power port protection

Stage 1 (Coarse protection): Gas discharge tubes (GDT), power SPDs.

Stage 2 (Intermediate protection): Metal-oxide varistors (MOV) + common/differential mode chokes.

Stage 3 (Fine protection): TVS diodes, RC networks, EMI filters.

(2) Signal and communication ports

Common-mode: GDT, common-mode chokes, Y-capacitors.

Differential-mode: Low-capacitance TVS, small MOVs, ferrite beads.

Shielding & grounding: Proper grounding of cable shields.

(3) Design considerations

Place protective components close to the interface, with short, straight traces.

Maintain impedance isolation between protection stages.

Regularly test and replace MOV/TVS devices to prevent aging failure.

6. Standards and Verification

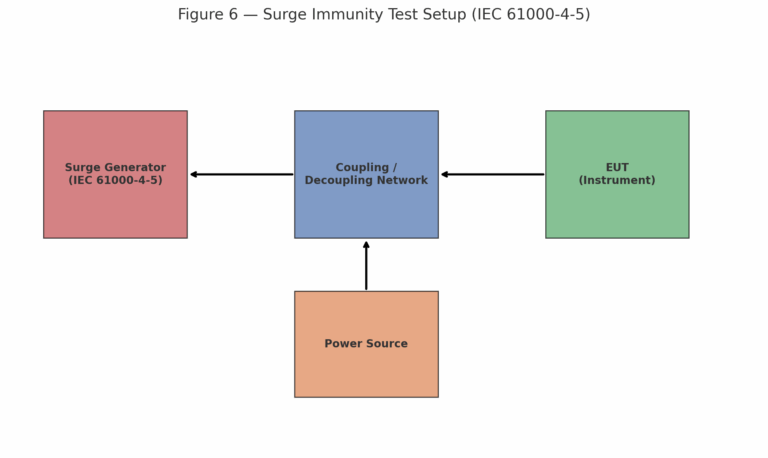

IEC 61000-4-5 / GB/T 17626.5: Surge immunity test standards.

Simulation scenarios: Lightning, power switching, short-circuit surges.

Test levels: 0.5 kV to 6 kV, depending on environment and installation.

For instrumentation, surge immunity tests must be conducted on both the power port and I/O ports to ensure reliability in real applications.

7. Conclusion

Surge is one of the most common and destructive transient threats in industrial systems. For instrumentation, it may cause:

Immediate failure → Downtime and costly repairs

Functional anomalies → Control and data errors

Accelerated aging → Increased maintenance costs

Therefore, surge protection must be addressed at the design, manufacturing, and selection stages. Through multi-stage protection, standardized testing, and proper maintenance, instruments can achieve long-term stability and reliability in complex environments.