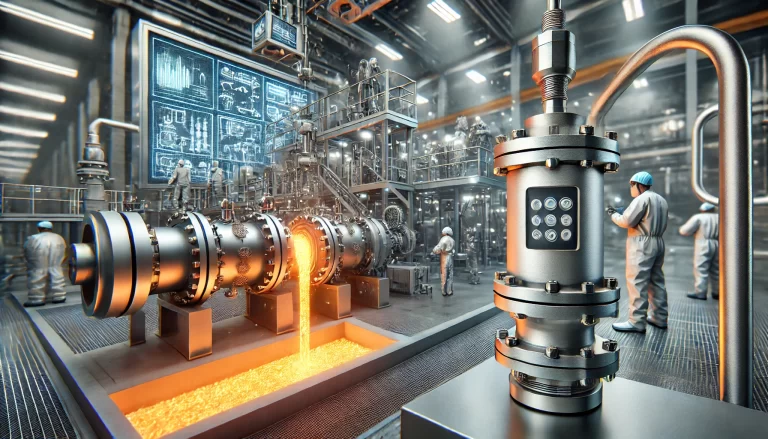

In modern industrial production, high-temperature melt pressure sensors play a critical role in measuring and controlling the pressure of high-temperature melts, fluids, and gaseous media. These sensors are widely utilized across various fields, including chemical fiber spinning, polyester rubber, plastic extrusion machinery, nonwoven fabric production, and the manufacturing of construction and packaging materials.

Definition and Working Principle

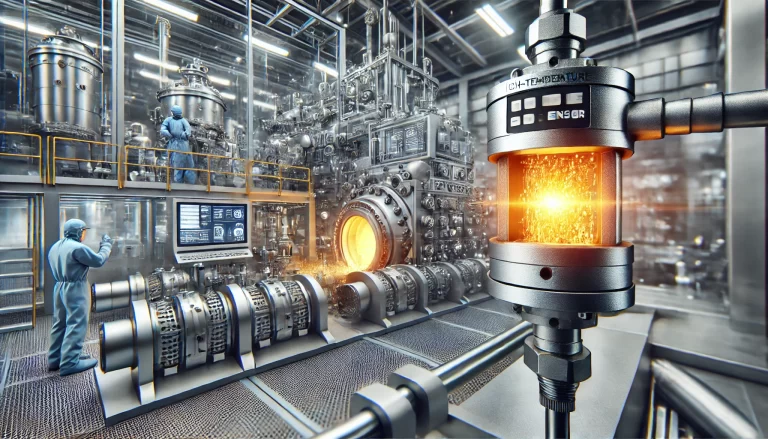

A high-temperature melt pressure sensor (commonly abbreviated as HTMPS) is a specialized electronic device designed to measure the pressure of molten substances under high-temperature conditions. The sensor operates based on the principles of either piezoresistive or piezoelectric effects.

When the pressure from the medium being measured directly acts on the sensor’s diaphragm, the diaphragm undergoes microdisplacement proportional to the medium’s pressure. This displacement causes changes in the sensor’s resistance or electrical charge. The device then processes these changes through electronic circuits, converting them into standard signals such as voltage or current, enabling accurate pressure measurement.

Key Features and Advantages

High-temperature melt pressure sensors possess several standout characteristics that make them indispensable in industrial applications:

High Precision: Modern HTMPS devices provide exceptional measurement accuracy, catering to demanding industrial requirements. As industrial technology advances, the precision of these sensors continues to improve, enabling measurements with minimal error margins.

Superior Reliability: These sensors are meticulously engineered to operate stably in extreme environments, often exceeding several hundred degrees Celsius. They exhibit remarkable resistance to thermal stress and maintain consistent performance even under prolonged exposure to harsh conditions.

Wide Temperature Range: HTMPS devices are designed to function across extensive temperature ranges, making them versatile for diverse industrial settings.

Intelligent and Remote Monitoring Capabilities: With the integration of IoT, big data, and AI technologies, modern sensors have evolved to support intelligent monitoring and remote operation. This capability enhances efficiency and safety in industrial processes by providing real-time data and automated alerts.

Applications Across Industries

High-temperature melt pressure sensors have a broad range of applications, extending to several critical industrial sectors:

Metallurgy: These sensors are integral to monitoring pressure changes in high-temperature equipment such as blast furnaces and converters, ensuring process stability and operational safety.

Glass and Ceramic Manufacturing: In industries requiring precision temperature and pressure control, these sensors help maintain production continuity and quality assurance.

Nuclear Power and Aerospace: The reliability and stability of HTMPS devices make them invaluable in high-risk environments like nuclear reactors and aerospace systems.

Petrochemical Industry: HTMPS devices measure pressure in high-temperature, high-pressure environments, such as reactors and pipelines, facilitating process control and safety monitoring.

Emerging Technologies:

Solar Photovoltaics: Sensors monitor pressure variations in high-temperature molten salt energy storage systems.

Electric Vehicles (EVs): They measure internal pressure changes within high-temperature battery packs to optimize performance and safety.

Technical Innovations and Future Prospects

As technology advances, HTMPS devices continue to evolve, incorporating cutting-edge innovations that enhance their capabilities and extend their applications:

Enhanced Materials: The development of materials with superior thermal and mechanical properties has increased the durability and lifespan of sensors under extreme conditions.

Miniaturization: Advances in microelectronics have enabled the production of smaller, more compact sensors without compromising performance. These are particularly beneficial in space-constrained applications such as aerospace and medical devices.

Integration with IoT: Modern HTMPS devices can now be integrated into IoT ecosystems, enabling seamless data collection, real-time monitoring, and predictive maintenance. For instance, sensors in industrial plants can alert operators to potential issues before they escalate, reducing downtime and enhancing efficiency.

AI-Driven Optimization: Artificial intelligence technologies are being used to analyze sensor data, optimizing industrial processes and improving decision-making. For example, AI algorithms can identify patterns in pressure fluctuations, predicting equipment wear or failures in advance.

Conclusion

High-temperature melt pressure sensors are pivotal in driving the efficiency, safety, and sustainability of industrial production. Their ability to withstand extreme conditions while delivering precise measurements makes them indispensable across a wide range of applications. As industries continue to embrace automation and smart technologies, the role of HTMPS devices will expand further, supporting the transition toward smarter, more efficient, and sustainable industrial processes. By integrating advanced technologies such as IoT and AI, these sensors are not only ensuring operational safety but also paving the way for future innovations in industrial automation.