Introduction to Flow Switches

A flow switch is a control switch that can monitor whether water, oil, gas or other media in a pipeline is flowing or not flowing, and then open or close it.

The flow switch can be set to an upper or lower limit. When the flow reaches the limit, the flow switch sends a signal or alarm, and the system will run or stop to avoid or reduce the host dry burning.

Common applications of flow switches include: pump protection, cooling water or heat exchanger, drain flow, safety valve tracking, etc. Generally, systems that require flow will use flow switches.

The main function of the flow switch is to trigger the alarm system when the flow of the medium reaches or exceeds the set value, and send an alarm signal to the control unit.

When the control unit receives this signal, it will issue a corresponding instruction to shut down or start the operation of the system, thereby achieving the function of flow control. It is widely used in the medium pipeline to monitor the size of the water flow in the water system.

Working Principle of Flow Switches

The working principle of the flow switch is based on the fact that when the medium flows in the switch, when the flow rate of the medium reaches or exceeds the set value, the flow switch will send an opening signal; and when the flow rate of the medium is less than the flow rate required for starting, the switch will send a stop signal. These two signals are input into the control system of the equipment to achieve the function of flow control.

Types of Flow Switches

Common ones include flapper flow switches, thermal flow switches and differential pressure flow switches.

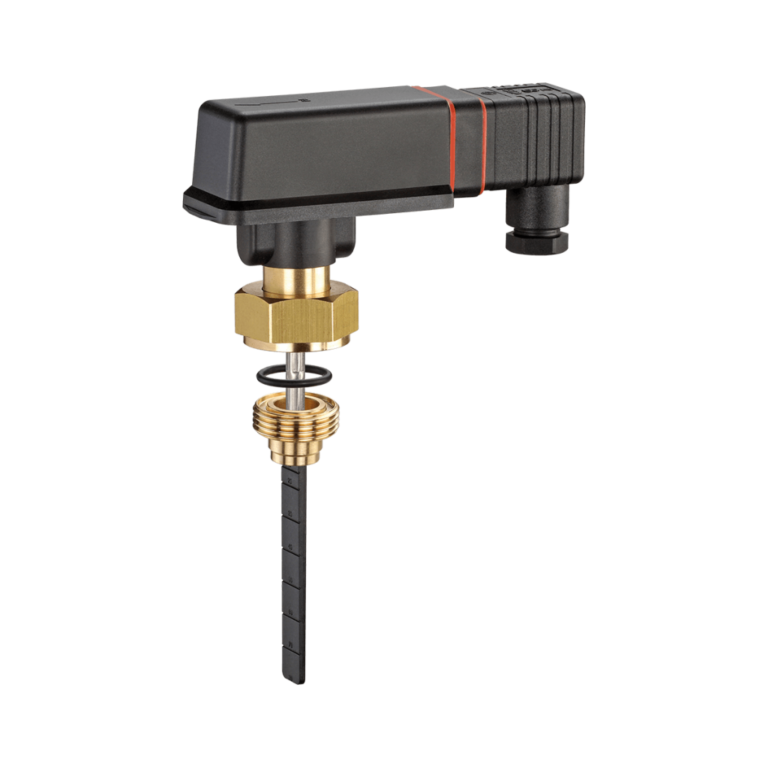

A flapper flow switch or plug-in flow switch is also called a mechanical flow switch.

The flapper flow switch is generally installed in the pipeline from the water outlet of the water pump to the water outlet of the equipment. It cannot be installed on the pipeline of the suction port of the water pump. This will prevent the water pump from absorbing water normally and the water flow switch from opening. Special attention should be paid to this.

The flapper flow switch allows horizontal (the wire part is on top) and vertical installation.

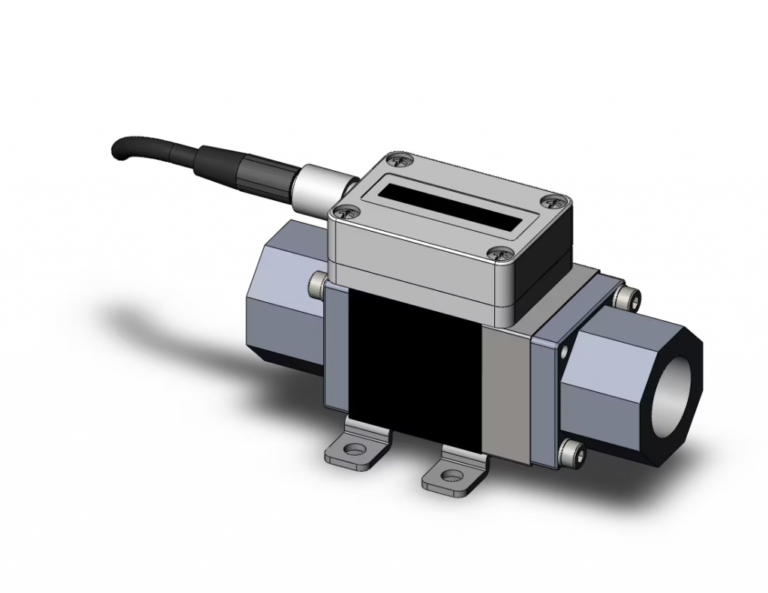

The flapper flow switch is a gas-liquid dual-purpose type, which can be widely used in industrial automation/mechanical equipment/air compression industry/refrigeration and air conditioning fields. In industrial occasions, it is specifically used in water-cooled welding machines, laser equipment cooling systems, vacuum coating machines, electric furnaces, polysilicon ingot furnaces, etc.; thermal flow switches are also called electronic flow switches.

The thermal flow switch is designed based on the principle of temperature change of the probe. The probe has a built-in heating sensor and a heat-sensitive sensor, which are in contact with the medium.

During measurement, the heating sensor emits a constant amount of heat. When there is no medium flowing in the pipeline, the heat received by the heat-sensitive sensor is a constant value. When there is medium flowing, the heat received by the heat-sensitive sensor will change with the flow rate of the medium. The heat-sensitive sensor converts the temperature difference signal into an electrical signal, which is then converted into a corresponding contact signal or analog signal through a circuit.

It is easy to install and the product is suitable for a variety of pipe diameter requirements; the flow switch can monitor the flow of liquid in the pipeline in real time and provide switch output; it can be used to monitor the flow rate of the fluid in the pipeline, monitor the flow interruption, or prevent the pump from running dry. It is widely used in various industries where it is necessary to monitor the flow rate of the fluid in the pipeline or to protect important equipment when the liquid flow fails.

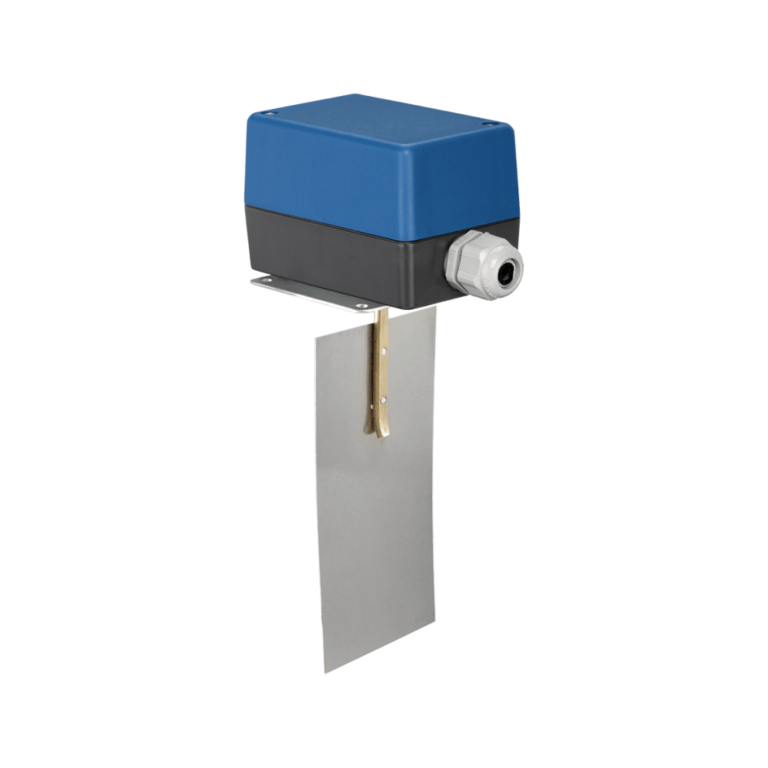

The differential pressure flow switch can measure the water flow by measuring the pressure drop at both ends of the valve, orifice plate, etc., to obtain accurate flow.

The flow is obtained by the pressure drop method. As long as the measured pressure difference on both sides of the differential pressure switch is compared with the preset value, the flow can be accurately controlled.

It is widely used in large, medium and small air-cooled or water-cooled chillers using plate heat exchangers, shell and tube heat exchangers and shell and tube heat exchangers for water flow control and monitoring of water pump and water filter status.