In modern mechanical engineering and equipment design, a clamp plays a critical role as a connection and fixing element in various industrial processes. It is widely used in equipment, pipelines, fittings, and mechanical systems. Whether in small household appliances or large industrial machinery, clamps serve an irreplaceable purpose.

This article will explore the structure, types, working principles, and application fields of clamps, shedding light on their indispensable role in industrial production.

1. Basic Structure of a Clamp

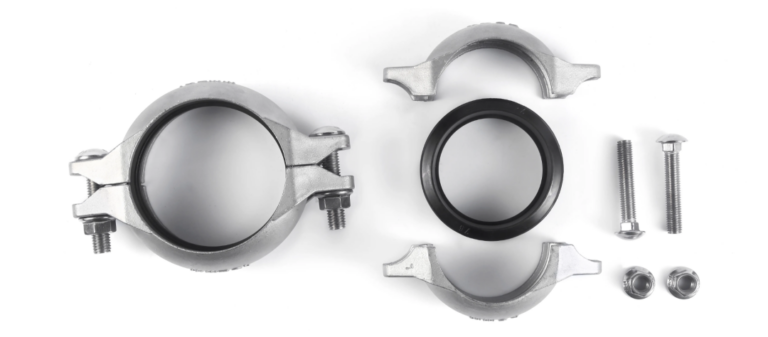

A clamp is typically made from metals or other corrosion-resistant materials, designed to be simple yet robust in structure. The primary components of a clamp include:

- Ring Structure: The main part of a clamp is a closed ring, usually formed by bending or welding, offering good load-bearing capacity.

- Fastening Device: To secure the clamp, it often includes bolts, nuts, or other types of fasteners. By turning these fasteners, the clamp can be tightened, ensuring the stability of the connected parts.

- Rubber Gasket or Liner: To enhance sealing and reduce friction, a rubber gasket or liner is often added to the inner side of the clamp. This gasket not only prevents direct metal contact with the pipeline or other parts but also effectively dampens vibrations.

- Materials: Clamps are made from various materials depending on the application requirements, such as stainless steel, aluminum alloys, plastics, and other synthetic materials. The choice of material directly impacts the clamp’s corrosion resistance, high-temperature tolerance, and load-bearing capacity.

2. Functions and Roles of Clamps

Clamps serve several essential functions in engineering systems:

Fixing Function: The primary role of a clamp is to firmly hold two ends of a pipeline or equipment together. In pipeline systems, clamps prevent the loosening or displacement of connected components (like pipes and fittings), minimizing the risk of leaks or system failure.

Sealing Function: In many industrial pipeline systems, it is crucial to maintain a tight seal at the joints to prevent fluid or gas leaks. Clamps, equipped with rubber seals or other sealing materials, can effectively seal the connection and prevent leakage.

Stabilizing Function: Clamps do more than just fix components; they also help reduce vibrations and shocks in pipelines or equipment. By tightening the clamp, vibrations within mechanical systems are minimized, leading to reduced wear and tear, ultimately prolonging the lifespan of equipment.

Adjustment and Maintenance: Clamps are not only used for fixing and connecting parts but also play a role in adjustment and maintenance. When performing equipment maintenance, clamps can be easily disassembled or adjusted, enabling tasks such as pipe replacement, cleaning, or other repairs.

3. Types of Clamps and Their Applications

Depending on specific application needs, there are various types of clamps, each designed for different structural requirements and functions. Common types include:

Single Ear Clamp: A basic clamp type typically consisting of a metal band and a fastening bolt. It is widely used in low-pressure systems for connecting smaller diameter pipes or components. Its simple installation and cost-effectiveness make it ideal for applications where the connection is not subject to high stress.

Double Ear Clamp: Made of two metal ears and a fastening bolt, this type is used for connections that require higher strength. Compared to single ear clamps, double ear clamps have better load-bearing capacity and shock resistance, making them suitable for industrial pipeline systems that handle higher pressures and vibrations.

Hydraulic Clamp: Hydraulic clamps use hydraulic pressure to provide a stronger fixing force, making them ideal for high-pressure pipelines. These are commonly used in industries such as oil, chemicals, and other sectors where manual tightening is difficult or impractical.

Quick Release Clamp: With an automatic tightening feature, quick release clamps can be installed and removed quickly, making them ideal for applications that require frequent maintenance or adjustment. These clamps are commonly found in fields like automotive and aerospace, where quick access and flexibility are important.

4. Industrial Applications of Clamps

Clamps, with their unique functionality and structure, play an essential role in various industries. Some of the major application areas include:

Piping Systems: In industries like construction, chemicals, oil, and natural gas, clamps are indispensable for the installation and maintenance of piping systems. They ensure the stability and sealing of pipe connections, preventing leakage and damage.

Mechanical Equipment: Clamps are used to secure components and enhance the stability of mechanical systems. For instance, in engine systems and pump devices, clamps are crucial for fixing pipes and parts, ensuring system reliability.

Automotive Manufacturing: In the automotive industry, clamps are used to secure exhaust pipes, fuel pipelines, and other components. They help reduce vibrations and noise, improving the comfort and performance of vehicles.

Aerospace: In the aerospace sector, clamps are particularly vital, especially in high-pressure, harsh environments. Clamps need to withstand extreme temperatures, pressures, and vibrations, thus requiring stricter material and design specifications.

Food Industry: During food processing and production, clamps are widely used in pipelines, pump systems, and other equipment connections. The food industry places high demands on hygiene and safety, so clamps are often made from stainless steel or other corrosion-resistant materials to ensure the food’s safety and cleanliness. Moreover, clamps must comply with FDA (Food and Drug Administration) certification standards to avoid any chemical reaction with food products.

Pharmaceutical Industry: In pharmaceutical manufacturing, clamps play a crucial role in fixing and connecting pipelines, tanks, reactors, and other equipment, ensuring that the production process is leak-free and contamination-free. In this industry, materials need to meet GMP (Good Manufacturing Practice) standards, and clamps are often made from non-toxic materials such as stainless steel or silicone to prevent cross-contamination.

5. Safety Standards and Quality Certifications

In many industries, clamps must meet strict safety standards and certifications to ensure their durability, safety, and functionality. Common standards include:

ISO 9001 Quality Management System: Ensures the manufacturing process of clamps adheres to international quality management standards.

ISO 14001 Environmental Management System: Ensures that the production process meets environmental protection standards, reducing environmental impact.

FDA Certification: For food and pharmaceutical industries, clamps must comply with FDA safety requirements to ensure they are non-toxic and safe for use.

CE Certification: In Europe, clamps must comply with CE certification, ensuring that they meet safety and reliability standards for the European market.

6. Conclusion

Clamps are crucial components in modern engineering, playing an essential role in ensuring the stability, safety, and efficiency of equipment and pipeline systems. Through their multifunctional design, clamps meet the needs of various industries by providing secure fixing, sealing, stabilization, and flexibility for adjustment and maintenance. As engineering systems become more complex, the importance of clamps in ensuring long-term system reliability and performance will only continue to grow.