1. Do You Really Understand Explosion-Proof Nameplates?

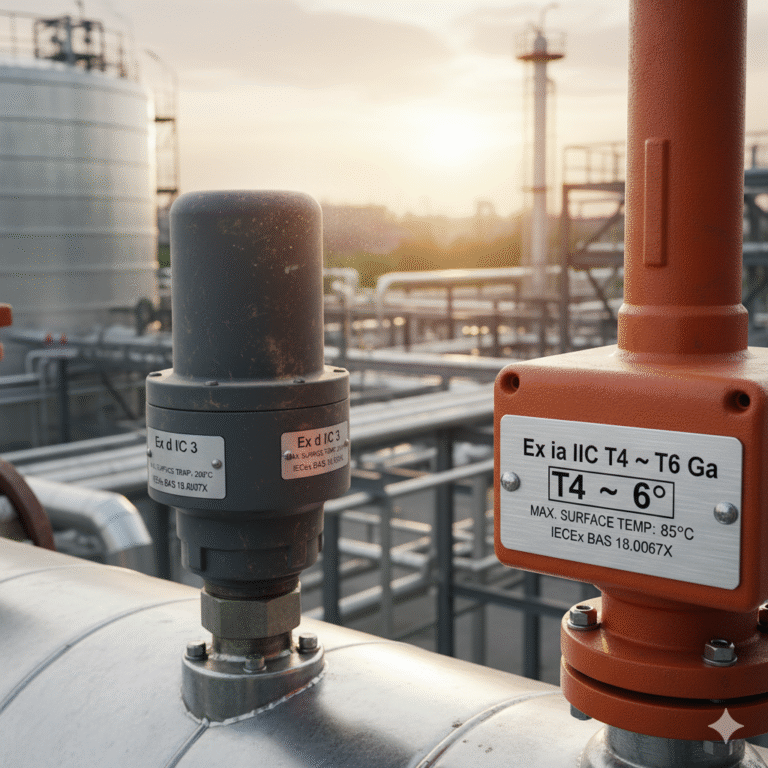

In chemical plants, it is common to see explosion-proof motors or vibrating level switches with nameplates marked with:

Ex ia IIC T4 ~ T6 Ga

While many engineers recognize this as the explosion-proof classification, the meaning of “T4 ~ T6” is often misunderstood.

This marking refers to the Temperature Class, which represents the highest permissible surface temperature of the equipment. In other words, it indicates the temperature that the equipment can safely control in an explosive gas environment without igniting the gas.

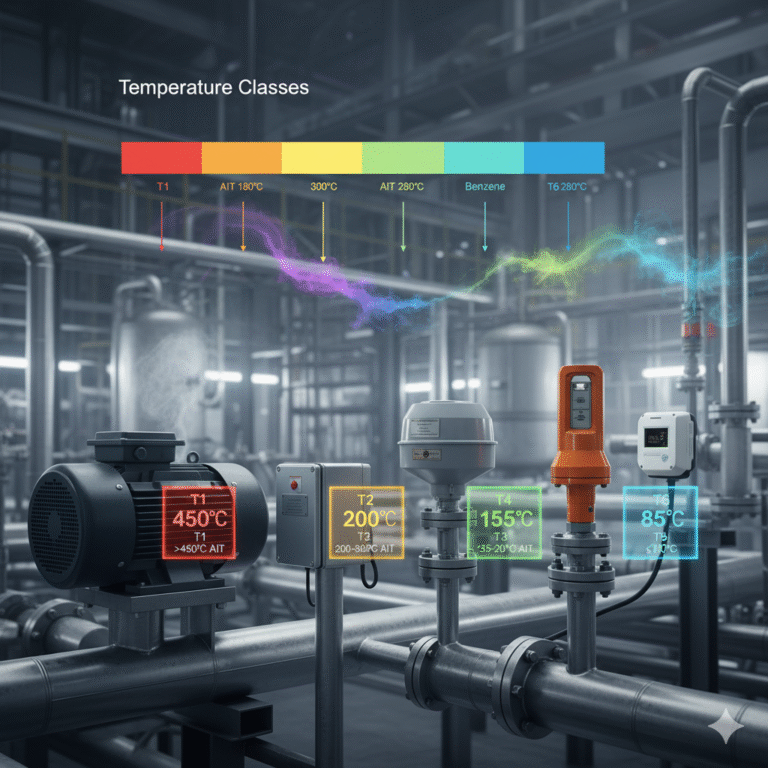

Some people mistakenly believe that T1 is “higher” than T6, but in fact, it’s the opposite. T1 allows a maximum temperature of 450°C, while T6 has a surface temperature limit of only 85°C. The higher the number, the lower the allowable temperature, meaning a higher explosion protection level.

2. Understanding Temperature Classes

Temperature classes are based on the difference between the highest possible surface temperature of the equipment and the ignition point of the combustible gases in the environment. Though different national standards exist, the core concepts are the same (see GB 3836.1 / IEC 60079-0).

| Class | Max Surface Temperature (°C) | Applicable Gas Auto-Ignition Point (°C) |

|---|---|---|

| T1 | 450 | > 450 |

| T2 | 300 | 300 ~ 450 |

| T3 | 200 | 200 ~ 300 |

| T4 | 135 | 135 ~ 200 |

| T5 | 100 | 100 ~ 135 |

| T6 | 85 | ≤ 100 |

For example:

If ether (with an auto-ignition point of about 180°C) is present in the environment, the equipment surface temperature must be ≤ 135°C (i.e., T4, T5, or T6 equipment would be suitable).

A T6 rated device would ensure that even in extremely hot environments, the surface temperature stays below 85°C, offering the highest level of safety.

3. Case Study

Background:

A radar level gauge with an Ex d IIC T3 rating was installed on a benzene storage tank. The gas phase temperature at the top of the tank was around 60°C, and during the summer, the tank wall temperature could reach up to 90°C. After operating for a while, the actual surface temperature of the device was measured at 182°C.

Result:

Though T3 allows for a maximum temperature of 200°C, the safety margin was only 18°C. When dust accumulated on the surface, the local temperature rose to 210°C, approaching the auto-ignition point of benzene (around 280°C).

The system was immediately shut down and rectified by replacing the equipment with a T4 ~ T6 rated vibrating level switch. After this change, the system ran safely for three years without issues.

4. Why Temperature Class Cannot Be Arbitrarily Lowered

Choosing a higher class (e.g., T6) means that the equipment is designed to meet stricter temperature control requirements.

Opting for a lower class (e.g., T3) in high-temperature environments may lead to unsafe conditions as the temperature approaches the critical threshold, compromising the effectiveness of temperature control and potentially damaging internal components.

While higher classes may incur slightly higher manufacturing costs, they provide exponentially greater safety margins.

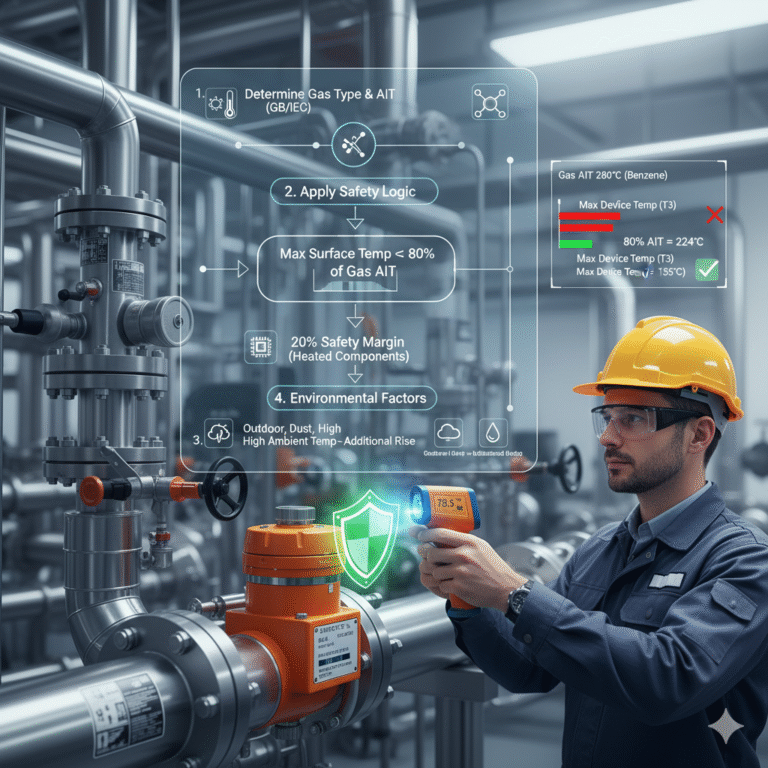

5. Proper Selection Logic

Determine the combustible gas classification and its auto-ignition point (refer to GB 3836.14, Appendix A).

Ensure that the Temperature Class on the equipment nameplate is suitable: Max Surface Temperature ≤ 80% of the gas auto-ignition point.

Allow at least 20% safety margin for high-temperature components (such as heated areas and electronic modules).

In outdoor, high-temperature, or dusty environments, consider the additional temperature rise effects.

6. Conclusion

The “T4” or “T6” markings on the nameplate may seem simple, but they represent a critical safety benchmark for your facility.

The core purpose of explosion protection is not just to prevent explosions, but also to prevent equipment overheating, thereby avoiding the ignition of hazardous gases.