In this era of rapid development of automated processes, manual measurement is about to become history and the radar material meter has become the most common level measurement tool today. However, in the process of measurement, it also faces various unexpected problems, so the measurement results will be inaccurate, resulting in errors for a number of reasons, the most important being these four aspects.

1. Dead space in the measurement process, resulting in inaccurate data

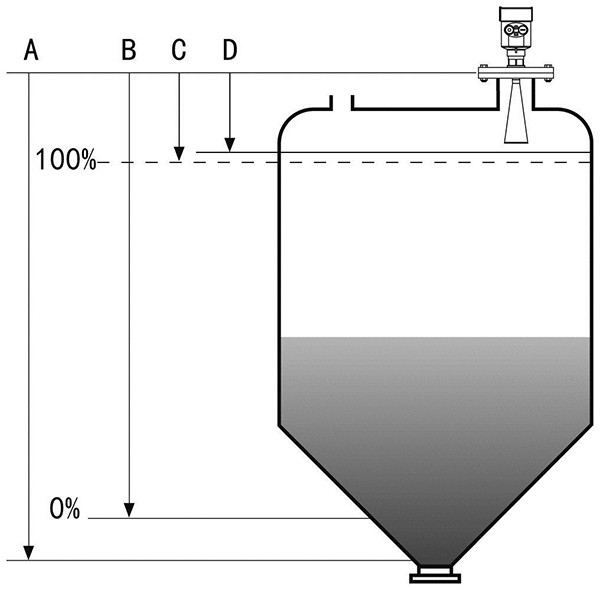

The output current of the instrument in the measurement is 4 – 20MA, because of the measured liquid itself and the radar material meter probe, so in the process of measurement there will be two dead ends (also become a blind spot), two dead ends (blind spot) is divided into two places, one is called the upper dead end (blind spot), the other has become the lower dead end (blind spot).

The upper dead center (blind zone) is the minimum distance that can be measured between the surface of the liquid and the upper reference point, approximately 0.1-0.5 m. The lower dead center (blind zone) is at the bottom below the instrument probe and the measurement results in this part do not change as the liquid in the tank actually changes.

2. Errors caused by the liquid being measured

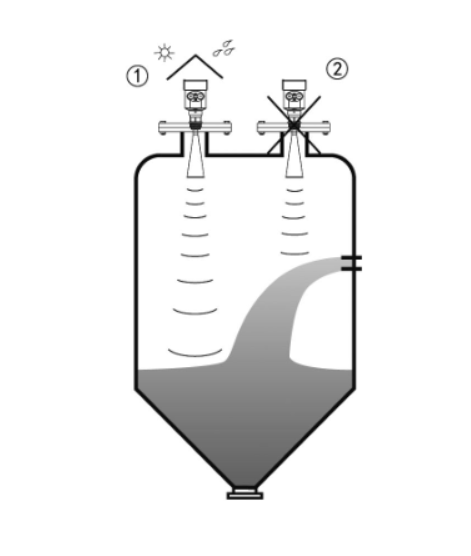

When measuring the boundary level, the dielectric constant of the liquid above must be 10. greater than the dielectric constant below, and when there is a difference of less than 10, the measurement results will become a waveform. Another situation is when the thickness of the upper liquid drops very low and measurements are carried out, as the time is taken for the liquid level and the boundary level are essentially the same, this can cause the two signals returned to be superimposed, thus affecting the measurement results.

3. The liquid to be measured is too viscous

If the liquid to be measured has a high viscosity, there is a high chance that it will adhere to the probe, thus affecting the signal and causing errors in the measurement data. When the viscosity goes further, it is very likely that the probes of the twin cables will stick together, causing inconvenience, so the probes should be cleaned regularly for maintenance.

4. The instrument itself generates errors

Radar level meter adopts advanced measurement technology, and is suitable for a variety of complex environments, with pressure, and corrosion resistance, not affected by temperature and humidity. Because the instrument causes errors, most of the reasons are due to incorrect installation on site, should be under the professional guidance of Huibo Xinrui engineers, in strict accordance with the instructions for use in accordance with the installation.