In industrial and daily temperature monitoring, axial and radial thermometers are two common types distinguished by the orientation of their dial head relative to the temperature sensing element. This difference significantly affects their installation and application scenarios. This article explores the differences across four key dimensions: working principle, structural characteristics, application scenarios, and selection guidelines.

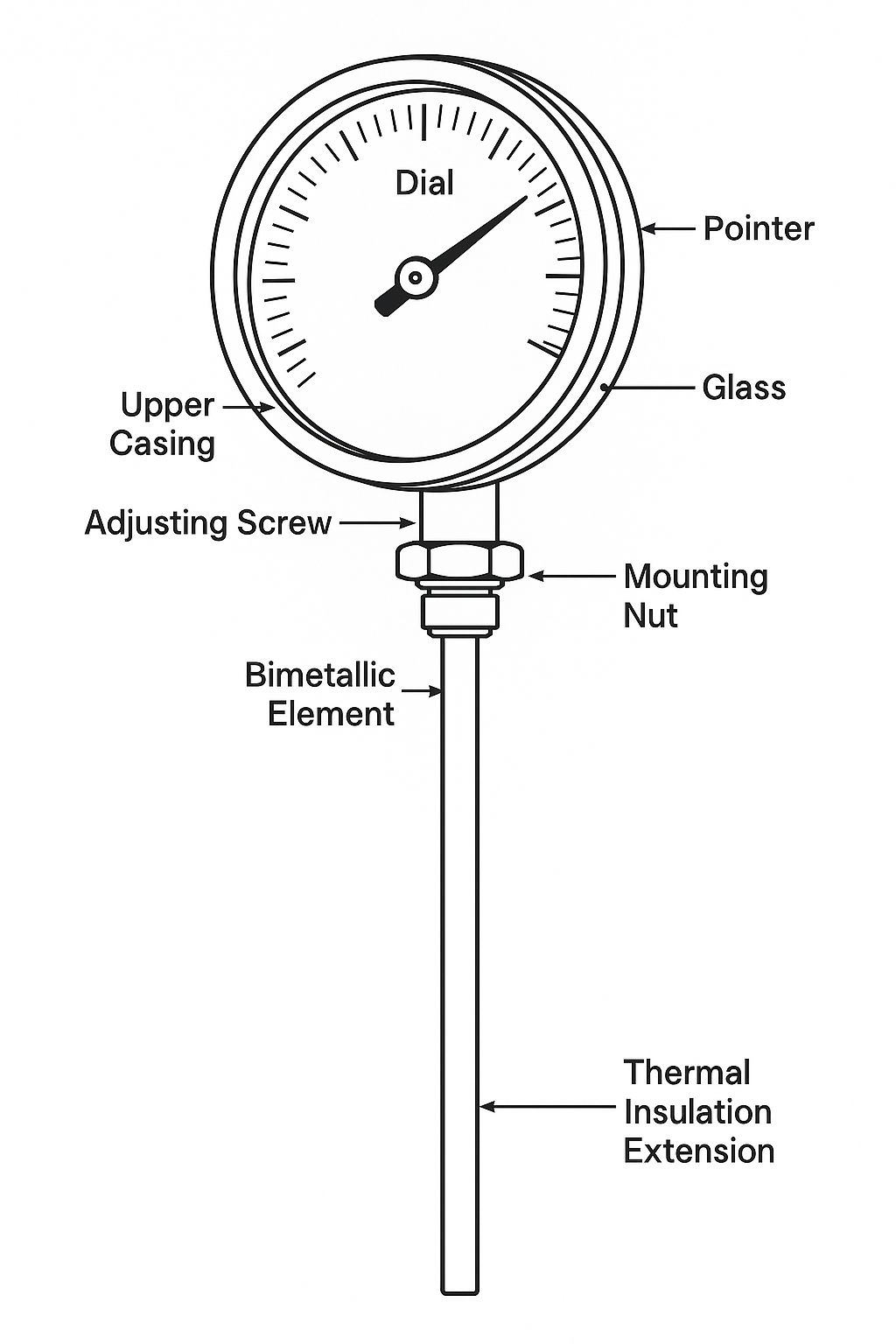

1. Working Principle and Structural Differences

🔹 Axial Thermometer

An axial thermometer features a coaxial design, where the dial head is aligned with the sensing stem. The pointer is directly mounted on the spindle, creating a linear layout. This structure allows the thermometer to reach deeper into the process medium.

Example Use: In a chemical reactor, an axial bimetal thermometer can be mounted via threaded or flanged connections, with the sensing probe fully inserted into the fluid to provide accurate internal temperature readings.

🔹 Radial Thermometer

A radial thermometer has a dial head positioned perpendicular to the sensing stem, typically using a bent-tube construction. The pointer connects to the spindle through a rotary spring mechanism. Its dial is parallel to the pipe or surface, making it ideal for side-view reading.

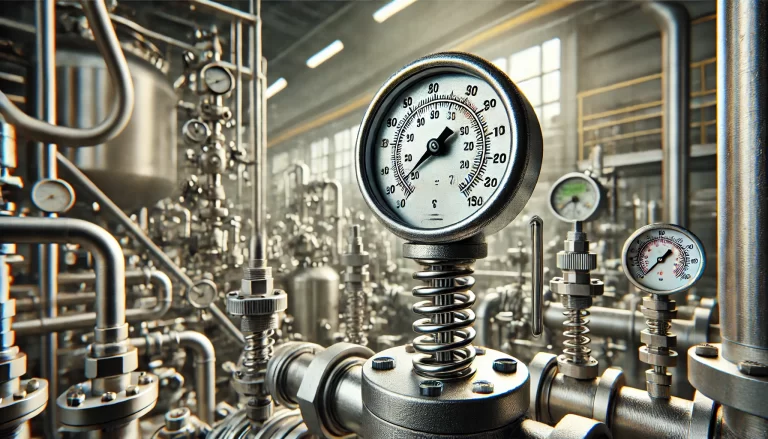

Example Use: On steam pipelines, a radial thermometer can be side-mounted using a clamp or flange. Operators can easily read the temperature without climbing or repositioning themselves.

2. Application Scenarios: When to Use Which Type

✅ Axial-Type Thermometers Are Ideal For:

Deep Immersion Measurements

Suitable for tanks, boilers, or applications where the sensor needs to reach the medium’s core to avoid surface heat interference.High-Temperature and High-Pressure Conditions

Built with high-grade materials like 316L stainless steel or titanium alloy. With IP65 protection, they operate reliably from -80°C to 650°C.Precision Environments

Often used in medical and laboratory settings for accurate monitoring of body temperature or chemical reactions.

✅ Radial-Type Thermometers Excel In:

Pipeline Side-Mounting

Especially useful on pipelines larger than DN80, avoiding flow disturbance by mounting on a straight pipe segment.Space-Constrained Installations

Compact design fits crowded control panels or equipment clusters.Explosion-Proof or Corrosive Environments

Fully stainless steel bodies and double-seal housings allow safe operation in acidic, alkaline, or explosive atmospheres.

3. Selection and Installation Guidelines

| Selection Factor | Recommendation |

|---|---|

| Installation Space | Use axial type if top clearance is available; use radial for side access or dense piping. |

| Measurement Depth | For depths >500mm, choose axial to ensure full probe immersion. |

| Corrosive/Explosive Media | Use 316L stainless steel with ATEX-certified models. |

| Ease of Maintenance | Radial types can feature rotatable dial heads for flexible viewing; axial types require full removal for maintenance. |

4. Real-World Case Studies

🏭 Axial Type in Pharma Industry

A pharmaceutical plant installed axial bimetal thermometers on reaction tanks. Each probe was inserted up to 1.5 meters to monitor temperatures ranging from 120°C to 180°C, ensuring stable synthesis conditions.

🔧 Radial Type in Power Plant

A thermal power plant used radial thermometers on steam pipelines. Installed via flanges, the units monitored 200°C to 300°C superheated steam. Dial orientation made routine inspection efficient and safe.

5. Summary: Axial vs. Radial – Which to Choose?

The choice between axial and radial thermometers depends on installation space, measurement depth, and environmental conditions:

Axial excels in deep insertion and vertical access applications.

Radial provides flexible reading angles and works best in horizontal or side-mounted environments.

To cover diverse industrial needs, consider universal (adjustable angle) designs (e.g., 135° models) that combine the advantages of both types for maximum adaptability and accuracy.