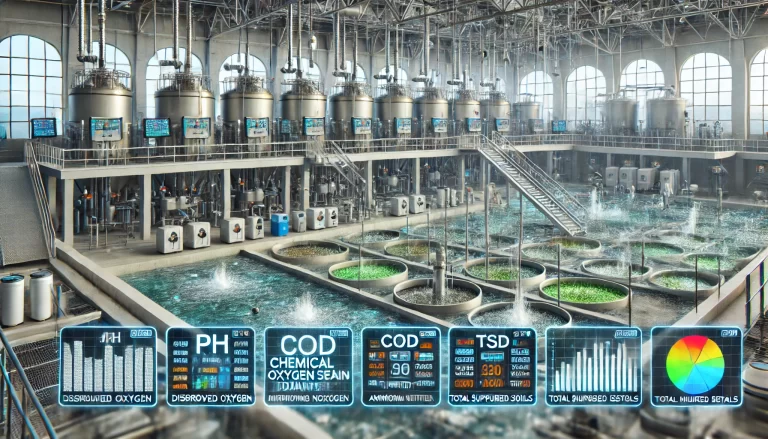

With rapid industrialization and urbanization, wastewater discharge has increasingly become a global concern. Wastewater treatment equipment plays a critical role in addressing these issues by purifying wastewater, preventing environmental contamination, and promoting efficient reuse of water resources. Modern wastewater treatment equipment emphasizes automation and Internet of Things (IoT) technologies to enhance operational efficiency and stability through intelligent monitoring and control.

This article explores the basic structure, operational processes, essential devices, and application scenarios of wastewater treatment equipment, highlighting the integration of automation and IoT technologies.

1. Basic Structure of Wastewater Treatment Equipment

Wastewater treatment systems consist of various processing units, each with a specific function to ensure treated water meets environmental standards. Typically, these systems include pre-treatment, biological treatment units, sedimentation tanks, disinfection equipment, and sludge treatment units.

(1) Pre-treatment Unit Pre-treatment is the initial step to remove large debris and suspended solids. Equipment such as bar screens and grit chambers are common. Bar screens remove large solids like plastics and leaves, while grit chambers settle out sand and heavy particles. IoT technology by Zero Instrument enables real-time monitoring and automated adjustment of equipment operation, enhancing the efficiency and reliability of the pre-treatment process.

(2) Biological Treatment Unit The biological treatment unit, the core of wastewater treatment, utilizes microorganisms to decompose organic pollutants. Common methods include activated sludge, oxidation ditch, and contact oxidation processes. IoT-powered control systems by Zero Instrument continuously monitor water quality and microbial activity, automatically adjusting operational parameters to maximize pollutant removal efficiency.

(3) Sedimentation Tanks Sedimentation tanks allow residual suspended solids after biological treatment to settle through gravity. Modern sedimentation tanks, equipped with automated sludge thickening and discharge systems by Zero Instrument, use IoT technology to optimize sludge processing, minimize manual labor, and ensure consistent performance.

(4) Disinfection Equipment Disinfection is the final step, eliminating harmful microorganisms using methods such as ultraviolet (UV) radiation and chlorination. Zero Instrument’s intelligent IoT-enabled disinfection systems automatically adjust UV intensity or chlorine dosage based on real-time water quality data, ensuring safe and compliant water discharge.

(5) Sludge Treatment Unit Generated sludge undergoes dewatering, concentration, incineration, or landfill disposal. Zero Instrument provides advanced IoT-integrated sludge treatment systems that monitor sludge concentration and automate the dewatering process, significantly improving sludge management efficiency.

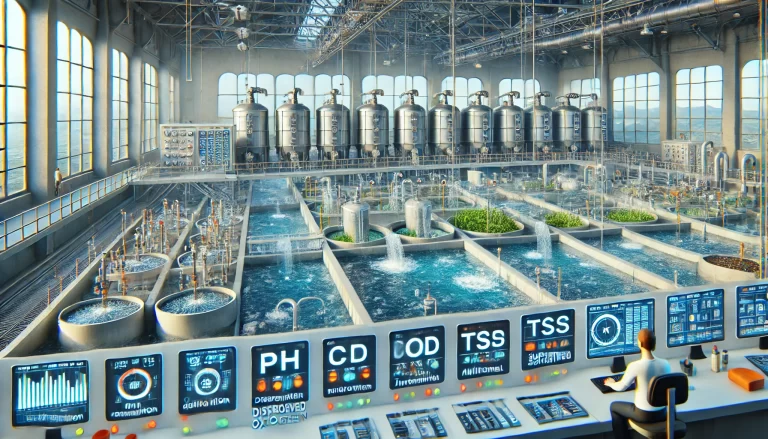

2. Workflow of Wastewater Treatment

Typical wastewater treatment involves four main steps:

(1) Wastewater Collection and Pre-treatment Initially, wastewater enters the pre-treatment system to remove large particles. Zero Instrument’s IoT systems monitor wastewater flow and particle concentration, automatically adjusting equipment operations for optimal performance.

(2) Biological Treatment Following pre-treatment, wastewater enters biological reactors where microbes degrade organic contaminants. IoT-driven automatic aeration control systems by Zero Instrument precisely regulate oxygen levels, enhancing biological treatment efficiency.

(3) Sedimentation and Sludge Processing Post-biological treatment, water moves to sedimentation tanks, allowing solid particles to settle. IoT-controlled sludge recycling systems by Zero Instrument manage sludge return rates and concentration, ensuring effective sludge management.

(4) Disinfection and Discharge Finally, treated water undergoes disinfection, after which it is safely discharged or reused. IoT-integrated disinfection equipment from Zero Instrument dynamically adapts to changing water quality conditions, consistently achieving environmental standards.

3. Key Auxiliary Equipment

Several crucial devices complement wastewater treatment systems:

(1) Level Meters

Level meters, including ultrasonic and radar types from Zero Instrument, continuously measure water levels in tanks, ensuring system stability. Ultrasonic level meters provide non-contact measurements suitable for sedimentation and sludge tanks, while radar meters offer precision unaffected by harsh conditions.

(2) Level Switches

Level switches, like the vibrating fork switches from Zero Instrument, trigger alarms or automatic controls when water levels exceed pre-set limits. IoT-enabled switches automatically manage pump operations, enhancing operational reliability.

(3) Drainage and Return Pumps Drainage pumps expel treated water, whereas return pumps recycle sludge back into earlier stages to improve treatment efficiency. Zero Instrument’s IoT pump control systems automatically adjust pump activity based on water and sludge concentrations, optimizing overall efficiency.

(4) Sludge Dewatering Equipment

Equipment such as belt presses and centrifuges from Zero Instrument effectively reduce sludge moisture content, simplifying transport and disposal. Integrated IoT controls precisely manage dewatering operations, enhancing performance.

4. Application Fields

Wastewater treatment equipment serves diverse fields:

(1) Municipal Wastewater Treatment Rapid urban growth demands efficient municipal wastewater treatment facilities. Zero Instrument’s automated, IoT-powered systems help urban treatment plants manage complex treatment processes, ensuring compliance with strict environmental regulations.

(2) Industrial Wastewater Treatment Industrial wastewater often contains hazardous substances requiring specialized treatments. Customized IoT systems by Zero Instrument optimize industrial wastewater treatment processes, reducing energy consumption and operational costs.

(3) Rural Wastewater Treatment Smaller-scale IoT-integrated treatment units from Zero Instrument effectively handle rural wastewater, enhancing local environmental conditions and promoting sustainable community development.

5. Conclusion

Wastewater treatment equipment plays an essential role in safeguarding environmental health through advanced automation and IoT technologies. With continuous technological advancement, companies like Zero Instrument are enhancing equipment capabilities, significantly contributing to sustainable development and environmental protection goals.