Measuring gas flow in industrial processes is crucial for safety, efficiency, and cost control. Two of the most common technologies are vortex flow meters and thermal mass flow meters. Both have unique strengths, but they operate on very different principles and are suitable for different conditions.

This article compares these two technologies in terms of working principle, accuracy, application suitability, installation, and cost—helping you choose the right solution for your gas flow application.

⚙️ 1. Working Principle

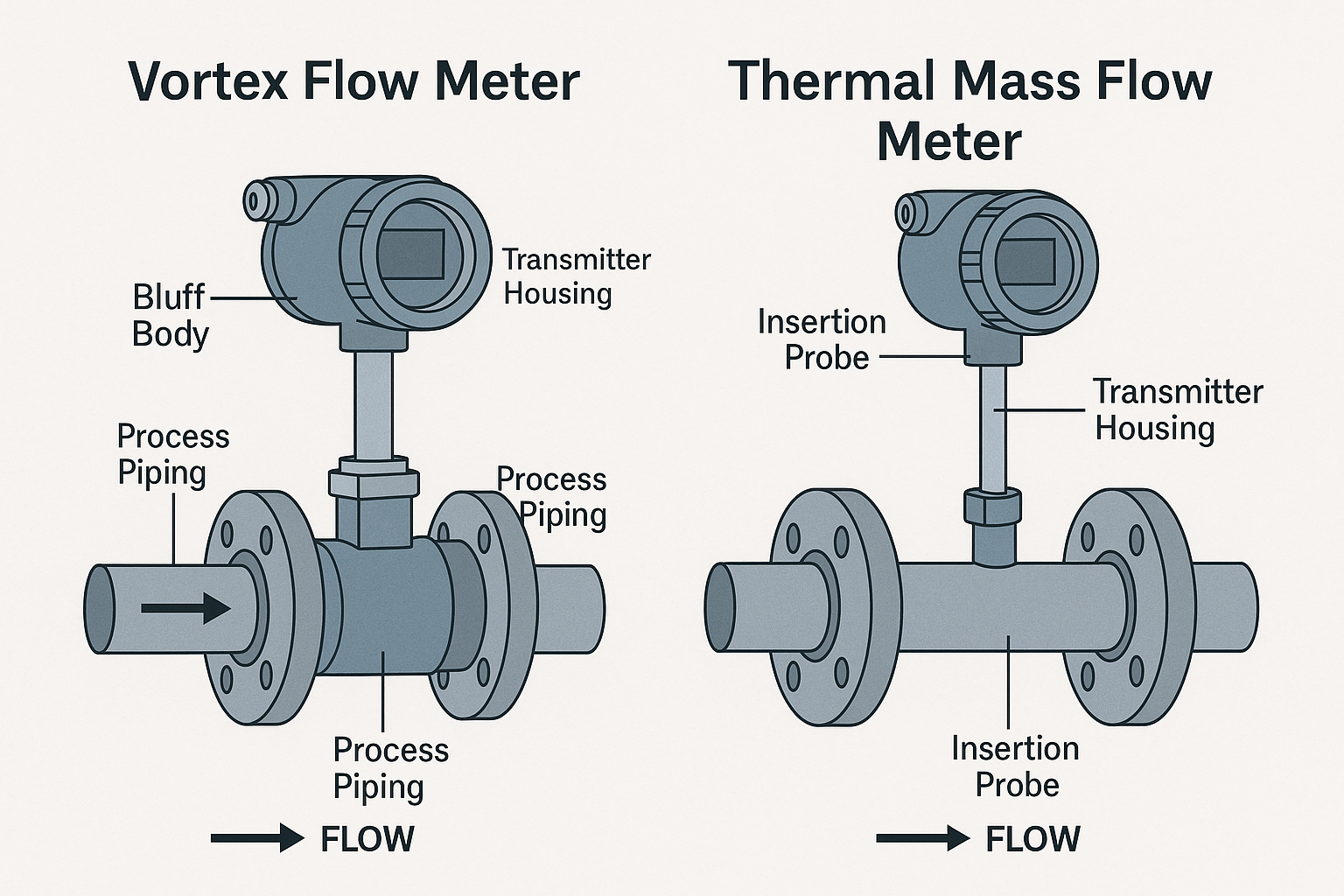

🔸 Vortex Flow Meter

Measures flow by detecting the frequency of vortices shed behind a bluff body as gas flows past it. The vortex frequency is proportional to velocity.

Measures volumetric flow

Requires temperature and pressure compensation for mass flow output

🔹 Thermal Mass Flow Meter

Measures flow by sensing the heat transfer from a heated sensor to the gas stream. The rate of heat loss is proportional to mass flow rate.

Measures direct mass flow

No need for external temperature/pressure sensors

📊 2. Performance Comparison Table

| Feature | Vortex Flow Meter | Thermal Mass Flow Meter |

|---|---|---|

| Measured Value | Volumetric (mass with compensation) | Direct mass flow |

| Accuracy | ±1.0% (with compensation) | ±1.0% to ±2.0% |

| Repeatability | High | High |

| Turndown Ratio | ~10:1 | Up to 100:1 |

| Sensitivity to Gas Conditions | Requires clean, dry gas | Sensitive to gas composition |

| Pressure/Temp Compensation | Required | Not required |

| Best for | High-pressure utility gases | Low-pressure, low-velocity gas |

🏭 3. Application Suitability

| Application Scenario | Recommended Meter Type | Reason |

|---|---|---|

| Compressed air measurement | ✅ Vortex Flow Meter | Rugged, reliable in dry gas |

| Natural gas for burner feed | ✅ Thermal Mass Flow Meter | Precise mass flow, no need for pressure sensor |

| Biogas or mixed gas | ❌ Thermal not ideal (gas mix sensitive) | Use vortex with compensation |

| HVAC duct gas flow | ✅ Thermal Mass Flow Meter | Handles low velocity well |

| Steam measurement (dry) | ✅ Vortex Only | Thermal not suitable for steam |

| Fluctuating pressure gas systems | ✅ Thermal Mass Flow Meter | Auto-compensates with built-in design |

🛠️ 4. Installation Considerations

| Factor | Vortex Flow Meter | Thermal Mass Flow Meter |

|---|---|---|

| Straight-run requirements | ≥15×DN upstream | Minimal (some insertion types require none) |

| Sensitivity to vibration | Moderate | Low |

| Pipe modifications | Inline or insertion | Inline or insertion |

| Maintenance | Low (no moving parts) | Requires occasional cleaning |

⚠️ Thermal meters can get fouled in oily or dusty gas, reducing accuracy.

💰 5. Cost Comparison

| Item | Vortex Flow Meter | Thermal Mass Flow Meter |

|---|---|---|

| Initial Cost | $$ | $$–$$$ |

| Installation Cost | Moderate | Low (especially insertion type) |

| Compensation Accessories | External (optional) | Not needed |

| Maintenance Cost | Low | Medium (cleaning required) |

✅ Conclusion

| If you need… | Choose… |

|---|---|

| Rugged measurement in compressed air or steam | ✅ Vortex Flow Meter |

| Accurate mass flow without pressure sensor | ✅ Thermal Mass Flow Meter |

| Wide turndown ratio for low-pressure gas systems | ✅ Thermal Mass Flow Meter |

| Mixed gas or unstable composition | ✅ Vortex (with compensation) |

| Measurement of wet steam or high temp fluid | ✅ Vortex Only |