The difference between the upstream and downstream pressures is called the pressure drop (△P) or differential pressure when the fluid flows through the valve.

If the pipeline size is the same both upstream and downstream of the valve and the velocity is constant, the valve must reduce the fluid pressure through friction losses to produce flow. Part of the valve friction loss is caused by the friction between the fluid and the valve wall.

However, this friction is very small and does not produce enough pressure drop for appropriate fluids. A more effective way to make the valve produce a significant pressure loss is through throttling in the valve body.

Because many valves are designed to allow a portion of the valve to be narrower than the pipeline, it is easy to provide throttling in the fluid layer.

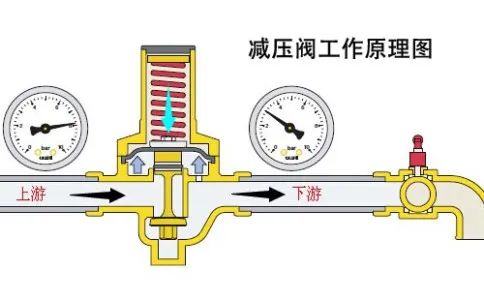

Because of the law of conservation, when the fluid approaches the valve, in order for the entire fluid to pass through the valve, its velocity must increase. Conversely, a corresponding pressure drop occurs.

The flow rate and low pressure occur downstream of the narrow neck, which is called the contraction section. Figure 2 shows that the contraction section is not at the throttling point itself, but at a distance downstream of the throttling, which varies with the pressure involved.

When the flow velocity of the flow at the contraction section is the maximum speed, the flow area of the flow layer is its minimum value.

After the contraction, the flow slows down and the pressure increases again, but not to the original upstream pressure value. The difference between the upstream and downstream pressures is caused by friction losses as the flow passes through the valve and is called the pressure drop.

The flow rate of the valve can be increased by reducing the downstream pressure. For liquid operations, the flow can be restricted by a pressure drop that falls below the vapor pressure of the flow, which will produce inwardly imploding bubbles and gas pockets (called cavitation or flashing, respectively).

Flow blockage occurs when the liquid flow has been saturated by the fluid itself mixed with bubbles or gas pockets, and it cannot be increased by reducing the downstream pressure. In other words, the formation of gas in the liquid fills the contraction and limits the flow that can pass through the valve.

For gases, flow blockage may also occur when the flow rate approaches the speed of sound, and the valve cannot increase the flow despite the reduction of downstream pressure.

Effects of High Pressure Drop on Valves

As discussed above, the following functions of valves depend on the presence of a pressure drop that allows the flow of fluid from an upstream vessel to a downstream vessel or to the atmosphere. Because the pressure drop is caused by the valve absorbing energy through friction losses, the ideal pressure drop allows the entire flow to flow through the valve body without excessive flow rates, absorbing less energy. However, some process systems may produce a large pressure drop through the valve due to system requirements.

High pressure drops across valves create many problems, such as cavitation, flashing, plugged flow, high noise levels and vibration. These problems cause many direct effects: wear and cavitation damage to the valve body and valve plug, failure or deterioration of the valve itself, calibration drift of attached instruments, pipeline fatigue or hearing loss to nearby workers.

In this case, valves operating under high pressure drops require the use of more expensive valve plugs, more frequent maintenance, large spare parts inventory and pipeline supports. These measures increase maintenance and engineering costs.

Although users are aware of the effects of high pressure drop, the biggest threat of high pressure drop is reduced efficiency of the process system. Because high pressure drop absorbs a lot of energy, energy is lost from the system. In most process systems, the energy added to the system is generated by the pressure of the boiler or pump.

When more energy is absorbed by the system, including the energy loss of the high pressure drop valve, a larger boiler or pump must be used. Therefore, if only a few high pressure drop valves are included in the system design, the system will be more efficient and smaller boilers and pumps can be used.

The problem of calculating the pressure drop of valves in the process

For a valve with an opening of 100%, the flow rate of the fluid flowing through case A and case B is the same, and the pressure before the valve in case A is smaller than the pressure before the valve in case B. So, compared with the valve pressure drop in case A and case B, which one is larger and which one is smaller? The key is why?

The main losses of pipelines are divided into losses along the way and local losses. Δh=ΣλL/d*(v²/2g)+Σξv²/2g. λ and ξ are coefficients, which need to be checked in the manual. L——-pipeline length. d——-pipeline inner diameter. v——-average flow velocity on the effective section, generally v=Q/s, where Q is the flow rate and S is the inner cross-sectional area of the pipeline. I hope you can understand.

From the above formula, it can be seen that the pressure drop of the valve should be larger in case B. Simply calculate the pressure drop of a valve (in the same environment) and estimate it by twice the pipeline.