Introduction

The performance of electromagnetic flowmeter liners under vacuum conditions directly impacts the measurement accuracy and service life of the instrument. In simple terms, the vacuum resistance of the flowmeter liner depends on two main factors:

The material strength and elastic modulus of the liner.

The adhesive bonding between the liner and the measuring tube (typically made of metal).

Analysis of Vacuum Resistance for Common Liner Materials

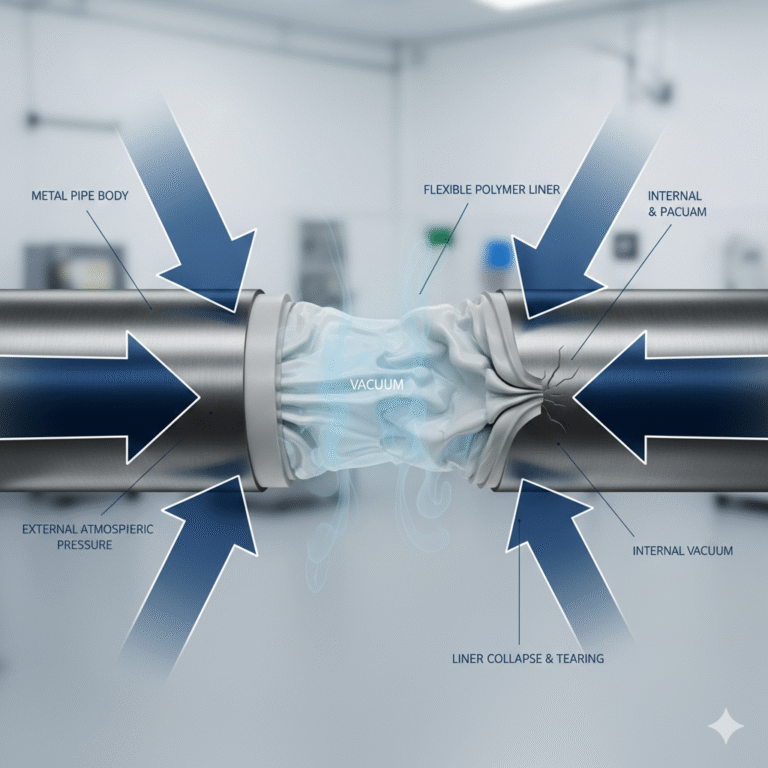

When negative pressure (vacuum) is generated inside the pipeline, the external atmospheric pressure becomes much greater than the internal pressure. This pressure difference tries to “peel” the liner off the tube wall or cause it to “collapse.” If the liner material lacks sufficient strength or adhesive bonding, it may wrinkle, deform, tear, or even detach, resulting in permanent damage to the flowmeter.

The following provides an analysis of the vacuum resistance of various common liner materials, ranked from best to worst:

Ceramic Liners (e.g., Alumina)

Vacuum Resistance: Excellent

Explanation: Ceramic liners are inherently rigid, with extremely high hardness. They are not adhered to the tube wall but are part of the measuring tube itself. Therefore, they are completely unaffected by vacuum pressure and will not deform or detach.

Applications: Highly abrasive slurries, corrosive media. Ceramic liners are ideal for vacuum and abrasion resistance, but they are the most expensive option.

Polytetrafluoroethylene (PTFE) Liners

PTFE liners need to be subdivided because their vacuum resistance varies greatly depending on the manufacturing process.PTFE (Compression-molded / Wrapped-molded)

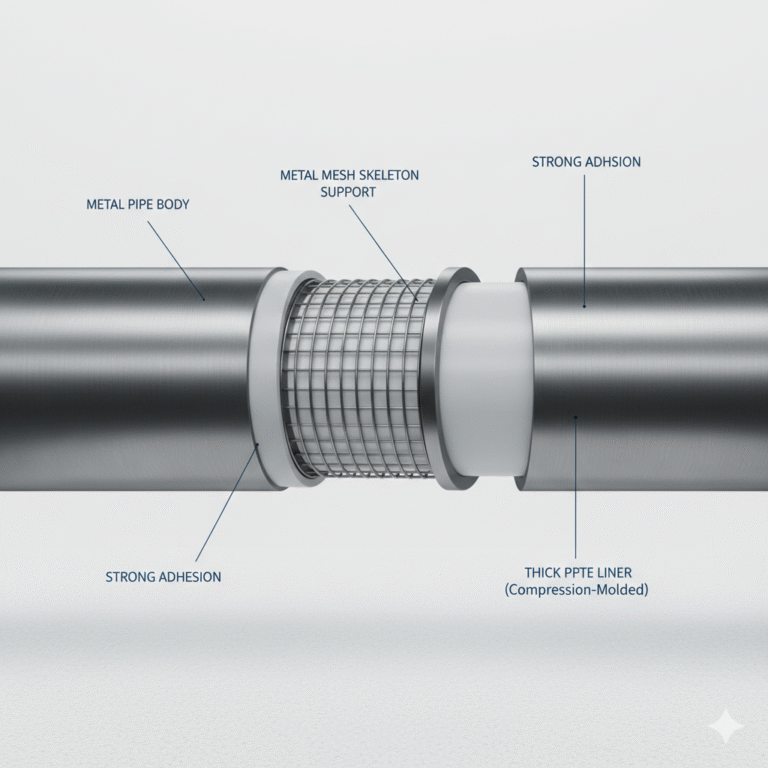

Vacuum Resistance: Good to Moderate

Explanation: This type of PTFE liner is thicker and tightly bonded to the metal tube, with a “backing” support (such as a metal mesh or a special structure), providing some resistance to vacuum pressure. High-quality PTFE liners can withstand certain levels of vacuum pressure, but excessive vacuum or rapid temperature changes can still risk delamination.

Key Point: PTFE liners with a skeleton support significantly enhance vacuum resistance.

Applications: Strong corrosive media such as concentrated acids, bases, and organic solvents. Always confirm the vacuum resistance with the manufacturer.

PTFE (Adhesive-backed Thin Film)

Vacuum Resistance: Poor

Explanation: This type of PTFE is a thin film bonded to the tube wall. Since PTFE itself is non-adhesive, the bonding strength is limited, and under vacuum, it can easily peel off from the interface or entire surface.

Applications: Not recommended for any vacuum conditions.

Perfluoroether Rubber Liners (FFKM/PMFE)

Vacuum Resistance: Good

Explanation: This material combines the elasticity of rubber with the chemical resistance of PTFE. As an elastomer, it deforms under vacuum, but its excellent elasticity and strong bonding to metal allow it to recover and avoid permanent damage. Its vacuum resistance is typically better than PTFE but not as high as PFA and ceramic.

Applications: Applications requiring excellent corrosion resistance and flexibility, such as media with particles.

Perfluoroalkoxy (PFA) Liners

Vacuum Resistance: Moderate

Explanation: PFA is a modified form of PTFE, offering better processability and stronger adhesion to metal than PTFE. However, its vacuum resistance is still limited and may fail under high vacuum or temperature conditions.

Applications: Corrosive media, typically in lower temperature applications than PTFE.

Polyurethane Rubber Liners (PU)

Vacuum Resistance: Moderate

Explanation: Polyurethane rubber is highly wear-resistant and has good toughness. Due to its elasticity and mechanical strength, it can withstand moderate vacuum pressures. However, prolonged exposure to high vacuum can lead to minor deformation.

Applications: Water, sewage, and slurry with neutral abrasive properties.

Chloroprene Rubber (CR), Nitrile Rubber (NBR), Ethylene Propylene Diene Monomer (EPDM) Liners

Vacuum Resistance: Moderate to Poor

Explanation: These general-purpose rubber liners are typically soft and elastic. They may perform fine under small or short-duration vacuum conditions, but due to their softness, they are prone to permanent wrinkles, bulging, or detachment under sustained or higher vacuum conditions. Among these, harder rubber varieties tend to perform better.

Applications: Water, sewage, dilute acids, dilute bases, non-abrasive, and non-corrosive media. Not suitable for vacuum conditions.

Typical Vacuum Resistance of Liner Materials at Room Temperature

| Liner Material | Vacuum Resistance | Typical Vacuum Resistance Range (Room Temperature) | Key Notes |

|---|---|---|---|

| Ceramic | Excellent | Absolute vacuum (-0.1 MPa) | Rigid structure, not affected by vacuum. Ultimate choice for vacuum applications. |

| PFA/PTFE (with skeleton support) | Good to Moderate | -0.08 MPa ~ -0.095 MPa | Supports like metal mesh significantly enhance resistance. Best for highly corrosive conditions. |

| PTFE (Adhesive-backed) | Poor to Moderate | Only for positive pressure | Easy to peel off under vacuum. Strictly avoid in vacuum conditions. |

| Perfluoroether Rubber (FFKM) | Good | -0.05 MPa ~ -0.08 MPa | Good elasticity and bonding strength. |

| PFA | Moderate | -0.03 MPa ~ -0.05 MPa | Better adhesion than PTFE but lower strength. |

| Polyurethane Rubber (PU) | Moderate | -0.02 MPa ~ -0.04 MPa | Wear-resistant and tough but can deform under prolonged vacuum. |

| Chloroprene (CR), Nitrile (NBR), EPDM | Poor to Moderate | -0.01 MPa ~ -0.03 MPa | Soft materials prone to damage under sustained vacuum. |

Key Factors Influencing Vacuum Resistance and Selection Guide

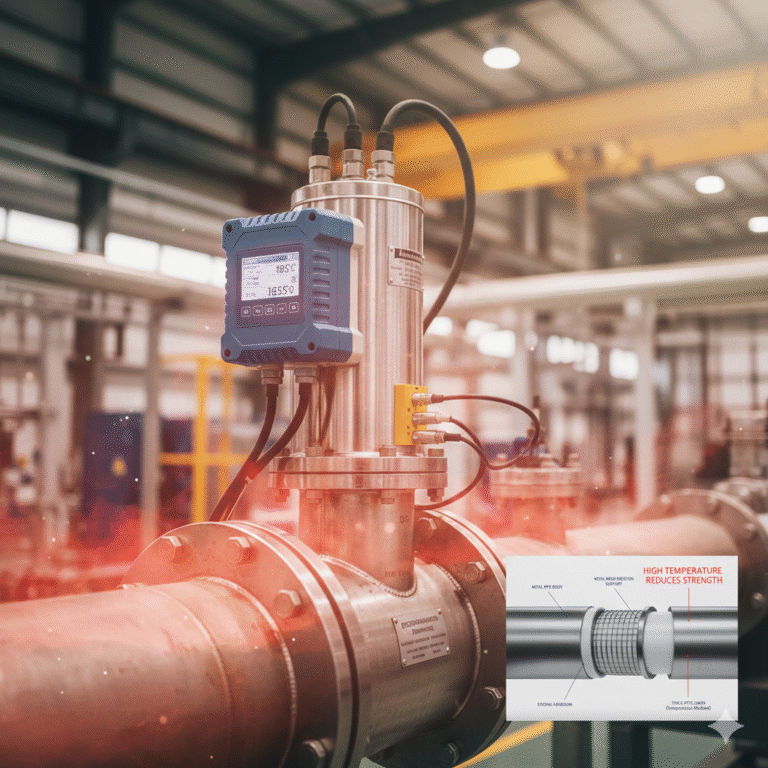

Temperature Impact

Nearly all liner materials lose strength and adhesive bonding capacity as temperature rises.

The vacuum resistance values provided by manufacturers are typically measured at 20°C. At higher working temperatures, their vacuum resistance will significantly decrease.

Manufacturing Process and Structure: The presence or absence of a “skeleton” support is crucial.

PTFE/PFA Liners: This is the most significant variable. Be sure to inquire whether the liner includes a metal mesh or skeleton for support. This support provides rigidity, greatly enhancing the material’s resistance to vacuum.

Manufacturer Expertise

The adhesive bonding process between the liner and metal tube (e.g., adhesive or sintering methods) directly affects their bonding strength. There can be significant differences in quality between different manufacturers.

Selection Process Recommendations

Identify Operating Conditions: Determine the maximum possible negative pressure in your pipeline and confirm the highest working temperature of the media.

Preliminary Screening:

Stable or High Vacuum: Choose ceramic liners or PFA/PTFE liners with skeleton support.

Mild or Short-term Vacuum with Corrosive Media: Consider perfluoroether rubber liners.

Mild Vacuum with Neutral Abrasive Slurries: Polyurethane rubber liners are a good choice.

Avoid Vacuum: If vacuum conditions are strictly prohibited, ensure system design avoids the possibility of vacuum generation (e.g., installing check valves or adjusting pump start/stop sequences).

Consult the Manufacturer:

Provide the manufacturer with your operating conditions (media, temperature, and maximum vacuum).

Request official vacuum resistance certification for the selected model at your required operating temperature.

Conclusion

While the table provides valuable reference data, the vacuum resistance of electromagnetic flowmeter liners is a highly “customized” parameter. When making a selection, do not rely solely on the liner material’s name; it is essential to understand the internal structure and manufacturing process. Always use the manufacturer’s written technical data as the final selection criterion.

In terms of process design, efforts should be made to avoid creating vacuum conditions at the flowmeter installation site. This can be achieved by installing check valves downstream or adjusting pump sequencing to prevent sudden vacuum situations.