1. Introduction

The V-cone flow meter—also known as an internal-cone or V-type cone flow meter—is an advanced differential-pressure flow measurement device first developed in the 1980s. Its introduction is widely regarded as a breakthrough in differential-pressure technology due to its unique throttling structure and exceptional measurement stability.

Designed for liquids, gases, and steam, the V-cone flow meter is available in both integrated and remote-mounted configurations. Unlike traditional orifice plates that rely on a central aperture, the V-cone uses an annular throttling area formed around a conical element suspended at the center of the pipe.

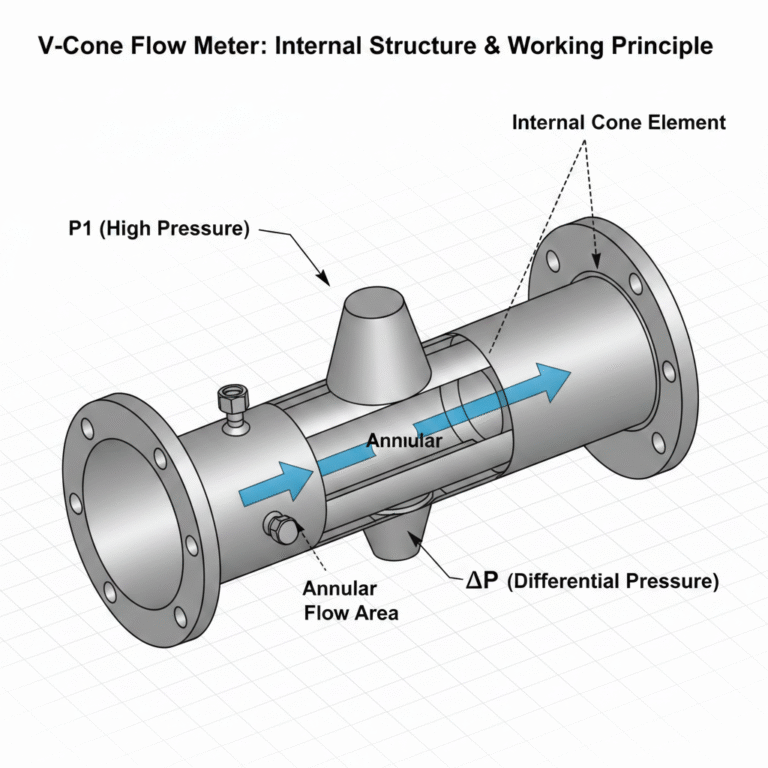

2. Working Principle

The V-cone flow meter operates based on the principles of the continuity equation (mass conservation) and Bernoulli’s equation (energy conservation).

When a fully filled pipeline fluid passes through the cone-shaped obstruction inside the meter, the flow area narrows around the cone. This geometry accelerates the fluid and reduces static pressure, creating a measurable differential pressure between the upstream (high pressure) and the low-pressure zone immediately downstream of the cone.

Since differential pressure is proportional to the square of flow rate, the volumetric or mass flow can be accurately calculated using the measured ΔP.

Key innovation:

The V-cone shifts the throttling region away from the pipe center to a stable annular flow path, reshaping the velocity profile and creating a highly repeatable and self-conditioning flow field, even under distorted or turbulent upstream conditions.

3. Main Features & Advantages

High Accuracy & Stability

Accuracy up to ±0.5%

Repeatability better than ±0.1%

Blunt-edge cone design forms a boundary layer that protects the cone from wear caused by dirty or abrasive media

Long-term stability without frequent recalibration

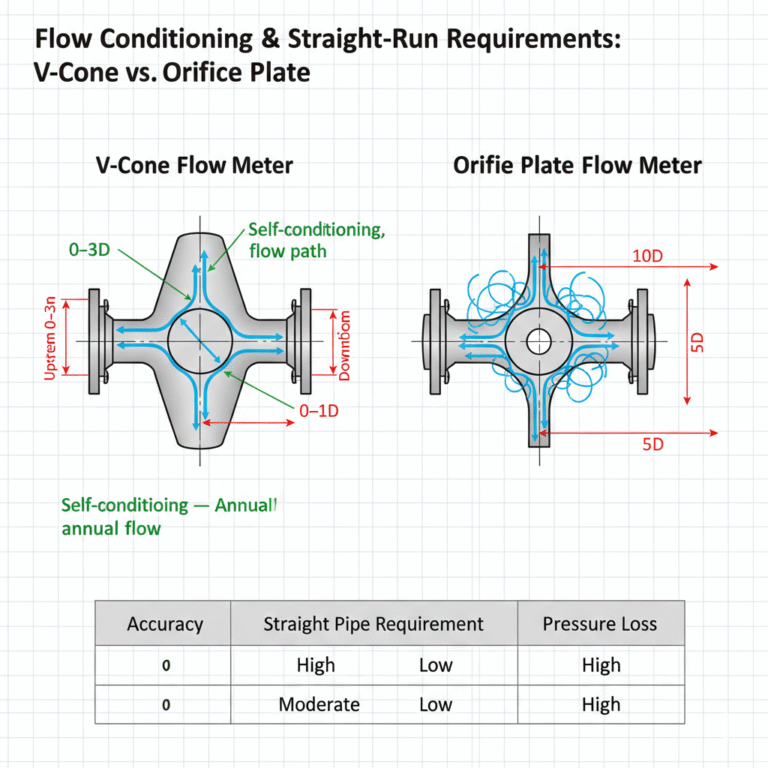

Minimal Straight-Run Requirements

Upstream: 0–3D, Downstream: 0–1D

Significantly shorter than traditional orifice plates (10D/5D)

Ideal for space-restricted installations and retrofit projects

Wide Rangeability

Typical turndown ratio: 10:1, up to 50:1

Suitable for low, medium, and high Reynolds numbers

Durability & Low Maintenance

Cone shape generates a “sweeping” effect that prevents buildup

Excellent resistance to erosion and contamination

Self-cleaning flow path ensures stable long-term performance

Low Permanent Pressure Loss

Pressure loss only 1/3–1/5 of an orifice plate

Comparable to Venturi meters

Reduces system energy consumption

Non-Clogging Design

Annular flow path allows solids and impurities to pass freely

Suitable for dirty, viscous, or multiphase media

4. Technical Specifications

| Parameter | Specification |

|---|---|

| Accuracy | ±0.5%, ±1.0% |

| Working Pressure | ≤16 MPa (up to 40 MPa optional) |

| Process Temperature | -40°C to 850°C |

| Ambient Temperature | -40°C to 70°C |

| Pipe Size | DN15–DN3000 |

| Output | 4–20 mA |

| Power Supply | 24 VDC |

| Turndown Ratio | 10:1 (max. 50:1) |

| Repeatability | <0.1% |

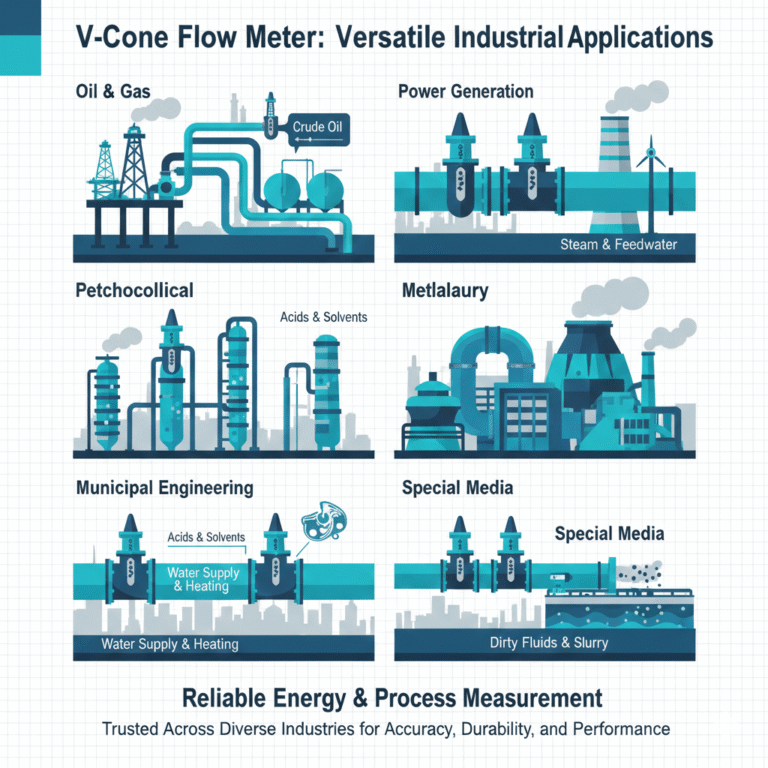

5. Application Areas

5.1 Industrial Sectors

Oil & Gas: crude oil, fuel oil, residue oil

Petrochemical & Chemical: acids, solvents, process fluids

Power Generation: steam, feedwater, condensate

Metallurgy: blast furnace gas, coke oven gas, oxygen

Municipal Engineering: water supply, district heating systems

5.2 Media Types

Gases: natural gas, air, flue gas

Liquids: water, hydrocarbons, chemicals

Steam: saturated and superheated

Special media: dirty fluids, slurry, gas–liquid two-phase flow

6. Comparison with Traditional Orifice Plates

| Performance Indicator | V-Cone Flow Meter | Orifice Plate |

|---|---|---|

| Accuracy | ±0.5% | ±1–2% |

| Straight Pipe Requirement | 0–3D upstream / 0–1D downstream | 10D / 5D |

| Turndown Ratio | Up to 15:1 | 3:1 |

| Pressure Loss | Low | High |

| Long-Term Stability | Excellent | Moderate |

| Suitable Media | Clean & dirty media | Mostly clean |

7. Installation Guidelines

7.1 Installation Environment

Avoid strong vibration areas

Reduce exposure to extreme temperatures or direct sunlight

Ensure good ventilation in corrosive environments

7.2 Installation Methods

Flanged type: DN50–DN3000; ideal for high-temperature or steam service

Wafer type: for small diameters; similar to vortex flow meter installation

Small-diameter integrated type: ≤DN40, fluid temperature ≤120°C

Butt-weld type: economical option for larger pipelines

7.3 Special Media Precautions

Steam: condensate pots must not be installed at the lowest point to avoid measurement error

Liquids in cold climates: protect transmitter chamber from freezing

8. Selection Guide

To size and select a V-cone flow meter, the following data is required:

Fluid name

Pipe inner/outer diameter

Flow units (kg/h, t/h, m³/h, Nm³/h)

Minimum, maximum, and normal flow rates

Operating pressure (MPa)

Temperature (°C)

Fluid density (kg/m³)

Preferred installation direction (horizontal/vertical)

Note:

Although highly versatile, V-cone meters must be selected based on actual process conditions to ensure measurement reliability.

9. Maintenance Recommendations

The V-cone has low maintenance requirements but periodic checks are recommended:

Inspect cone and pipe interior for buildup

Clean if necessary

Check all seals for leakage

Calibrate the differential pressure transmitter at intervals

Extra inspection for devices operating under extreme high-pressure or high-temperature conditions

10. Conclusion

The V-cone flow meter is a robust, accurate, and low-maintenance differential-pressure device that offers a superior alternative to traditional orifice plates. With excellent long-term stability, wide rangeability, low installation requirements, and compatibility with challenging media, it is increasingly adopted across oil & gas, chemicals, power, metallurgy, and municipal applications for reliable energy and process measurement.