In modern industrial environments, accurately measuring the liquid level in oil sludge tanks is critical for operational safety, efficiency, and environmental protection. Guided wave radar (GWR) level meters are advanced instruments known for their high precision, reliability, and ability to function in harsh conditions. This article explores the application of GWR level meters in sludge oil tanks, highlighting their advantages, operational principles, and key considerations.

How Guided Wave Radar Level Meters Work

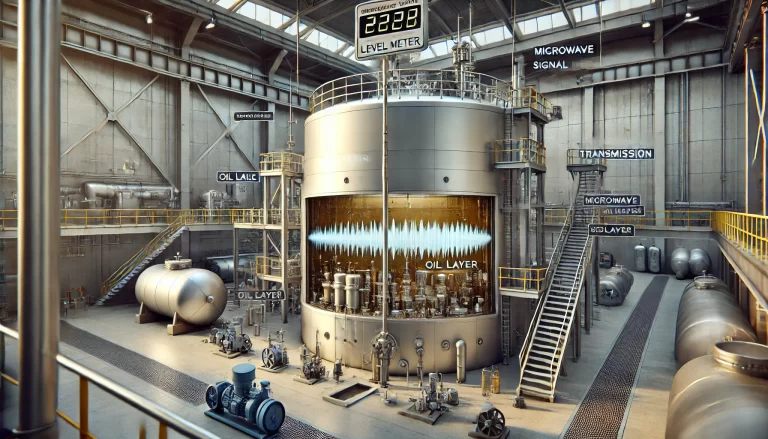

GWR level meters use a waveguide—typically a metal rod or cable—along which microwave signals travel. When the signal encounters the medium’s surface, a portion of it reflects back to the transmitter. The time difference between signal emission and reception is used to calculate the liquid level with precision.

This measurement method is particularly effective in sludge oil tanks. Sludge oil has a high dielectric constant, enabling microwave signals to travel efficiently through the medium. One of the unique benefits of GWR is its ability to penetrate surface oil layers and measure the actual liquid level beneath, regardless of the thickness or instability of the sludge. This feature ensures consistent and accurate readings even when the oil layer fluctuates or thickens over time.

Advantages of GWR in Sludge Oil Tank Measurements

Resilience in Harsh Environments

Sludge oil tanks are often exposed to extreme conditions, such as high temperatures, pressure, and corrosive environments. GWR level meters are constructed with materials that resist heat and corrosion, ensuring long-term stability and reliable performance under extreme conditions. Their sealed design also prevents sludge from entering the instrument, reducing maintenance requirements and extending equipment lifespan.Minimized Interference from Environmental Factors

Oil tanks are often filled with potential electromagnetic interference (EMI) sources, such as motors and electrical cables. GWR systems, using waveguides to transmit signals, are highly resistant to such interference, delivering accurate and stable readings despite the presence of external disturbances.Low Maintenance and Simple Calibration

GWR level meters are easy to install and maintain, requiring minimal calibration compared to other level measurement instruments. Regular calibration, when needed, involves adjusting the meter based on standard reference points (such as a fixed-height marker) to ensure ongoing accuracy. Periodic verification of the instrument helps detect potential issues early, maintaining stable and reliable performance over time.

Challenges Addressed by GWR Level Meters

Thick and Fluctuating Oil Layers:

In many sludge tanks, thick or uneven layers of oil form on the surface. GWR technology penetrates these layers without affecting the measurement accuracy of the actual liquid level below.Extreme Operating Conditions:

High temperatures, corrosive substances, and pressure can degrade most measurement instruments. However, the durable construction of GWR meters ensures continuous and accurate measurements in these conditions.Electromagnetic Interference:

Sludge oil tanks are often located near equipment that generates EMI, such as pumps and motors. GWR’s signal transmission along waveguides minimizes the impact of such interference.

Best Practices for Calibration and Use

While GWR level meters are reliable and require minimal calibration, routine calibration is still necessary to ensure optimal performance. Calibration can be done using standard reference points to fine-tune the meter’s parameters. Additionally, regular verification ensures that any potential errors or deviations are identified and corrected early, preventing measurement drift over time.

Conclusion

Guided wave radar level meters offer significant advantages in sludge oil tank measurements. Their ability to deliver high-precision and reliable data, even under harsh environmental conditions, makes them indispensable tools for industrial operations. With their resistance to interference, ease of maintenance, and minimal calibration requirements, GWR level meters help improve operational efficiency while reducing costs. When used properly, they ensure safe and environmentally sound operations, whether dealing with liquids, solids, or complex industrial conditions.

By selecting the right GWR level meter and following best practices, industries can enhance the accuracy and efficiency of sludge oil tank measurements, ensuring smooth and trouble-free production processes.