Introduction

In the flow meter industry, zero drift—also known as zero offset—is the deviation of the flow meter’s output signal from the ideal value under zero flow conditions. Addressing this phenomenon is critical to maintaining accuracy and reliability in various applications. This article explores the causes, impacts, and mitigation strategies for zero drift, complemented by real-world examples and suggested visual aids.

Causes of Zero Drift

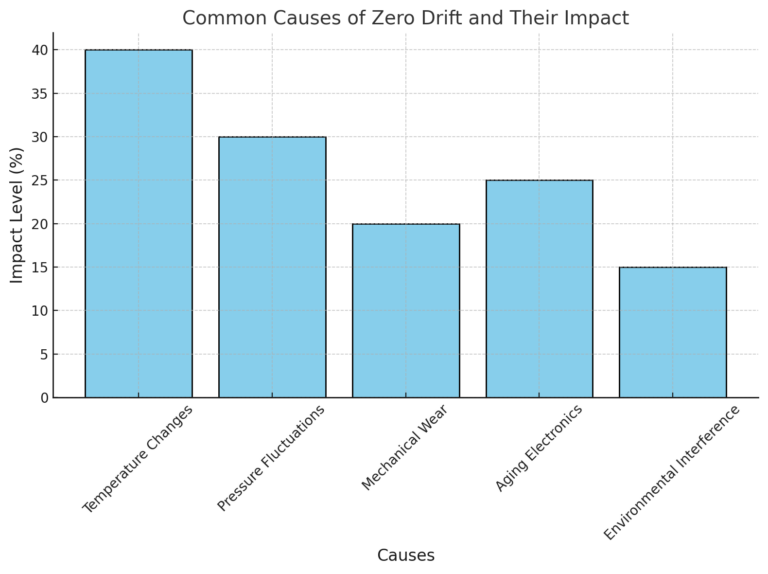

Zero drift can result from several factors, including environmental, mechanical, and electronic influences:

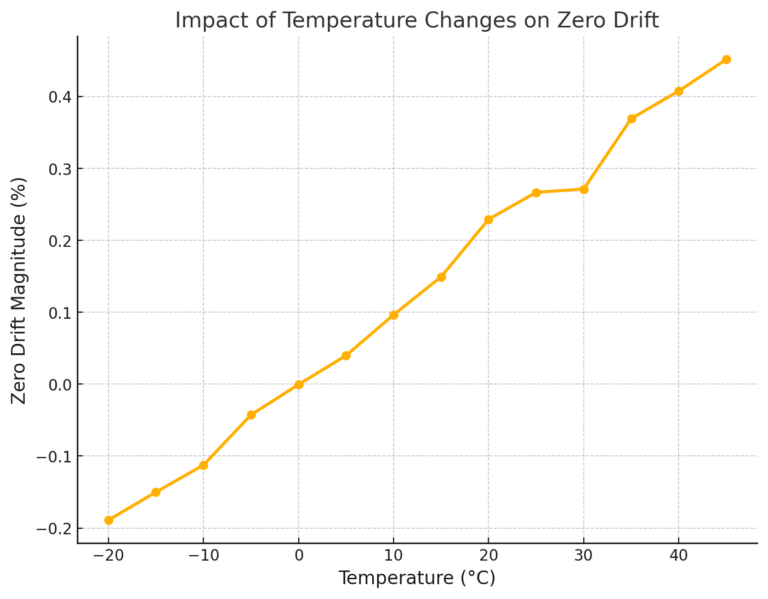

Temperature Variations

Components inside the flow meter, such as sensors and electronics, are sensitive to temperature changes. For instance, in environments with daily temperature fluctuations of ±10°C, a turbine flow meter might exhibit a zero drift of ±0.5% over time.Suggested Visual: A graph showing zero drift magnitude versus temperature changes.

Pressure Fluctuations

Inconsistent pressure in the flow system may lead to signal instability. For example, during rapid pressure drops in pipelines, Coriolis flow meters might display drift due to sensor deformation.Mechanical Wear and Tear

Long-term use of mechanical parts like rotors and bearings in flow meters can degrade their accuracy. A magnetic flow meter used in high-viscosity fluid measurements may experience significant wear over five years.Aging of Electronic Components

Capacitors, resistors, and other electronic elements degrade over time, altering signal processing. For instance, electronic drift in an ultrasonic flow meter might lead to erroneous readings after prolonged use without recalibration.Sensor Sensitivity Loss

Sensors subjected to harsh chemicals or extreme conditions can lose sensitivity. A thermal mass flow meter exposed to corrosive gases, for example, might show a 2% deviation after two years.External Environmental Interference

Electromagnetic interference (EMI) from nearby machinery or power lines can disrupt flow meter signals.Suggested Visual: Diagram showing interference sources and their impact on the flow meter’s signal.

Impacts of Zero Drift

Zero drift can have far-reaching consequences, especially in precision-critical environments:

Inaccurate Measurements: A zero drift of ±1% in a water management system handling 10,000 gallons/day results in a measurement error of ±100 gallons.

Process Inefficiencies: In manufacturing, incorrect readings might lead to underfilling or overfilling, wasting resources.

Regulatory Non-Compliance: Industries like pharmaceuticals or oil and gas require stringent adherence to measurement accuracy. Zero drift can lead to costly penalties.

Poor Decision-Making: Erroneous data compromises operational and strategic decisions.

Suggested Visual: Case study comparison of a system before and after mitigating zero drift, showing productivity gains.

Mitigating Zero Drift: Practical Strategies

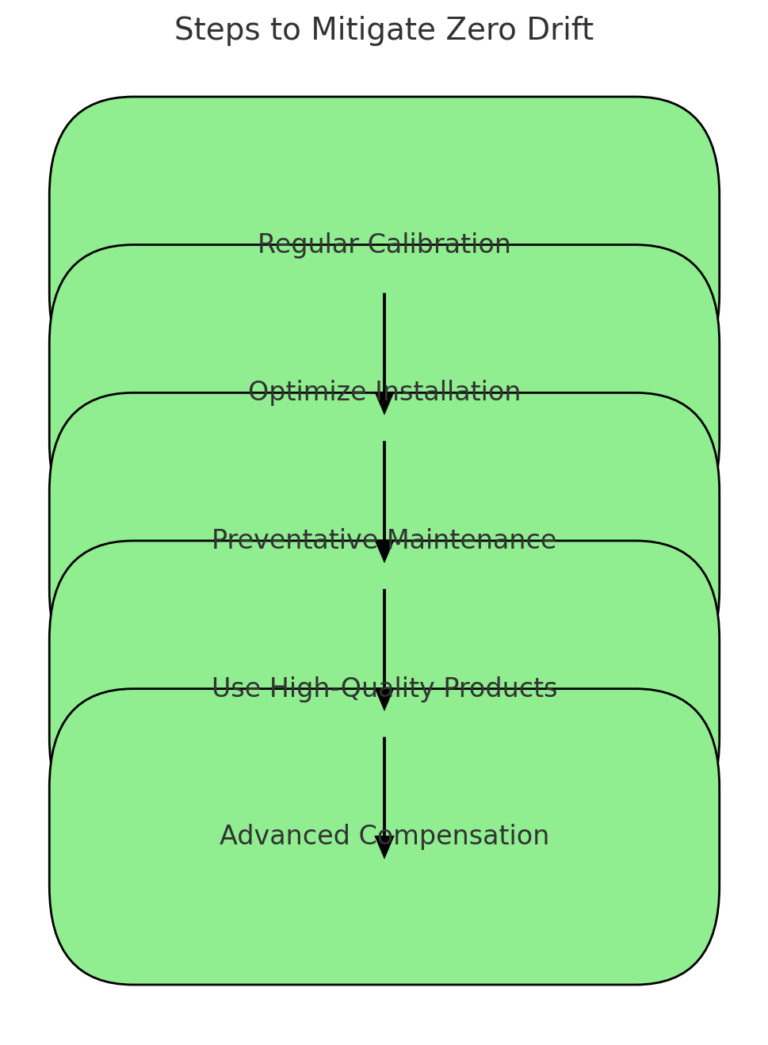

Regular Calibration

Periodically recalibrate flow meters to realign their output with the actual zero flow state. For example, recalibrating a differential pressure flow meter every six months can reduce drift-related errors by 80%.Optimized Installation

Ensure proper installation to minimize external interference. For instance, magnetic flow meters should be placed away from high-voltage equipment to reduce EMI.Preventative Maintenance

Regularly inspect and maintain flow meter components to prevent wear and tear. Maintenance logs from a natural gas pipeline showed a 15% reduction in drift after routine lubrication and part replacement.High-Quality Products

Invest in advanced flow meters with robust designs and minimal susceptibility to zero drift. Products with built-in compensation mechanisms, such as temperature sensors, can automatically adjust for environmental changes.Advanced Compensation Techniques

Use flow meters with self-correction algorithms. For example, smart Coriolis meters can detect drift patterns and adjust their signals in real time.Suggested Visual: Flowchart showing steps in automated compensation.

Conclusion

Zero drift is a significant challenge in the flow meter industry, affecting measurement accuracy and operational efficiency. By understanding its causes and employing appropriate mitigation strategies, users can ensure optimal performance and reliability of flow meters.

Implementing the measures discussed—regular calibration, proper maintenance, advanced technologies, and environment-specific installation—can significantly minimize zero drift’s impact, providing accurate and consistent measurements in any application.