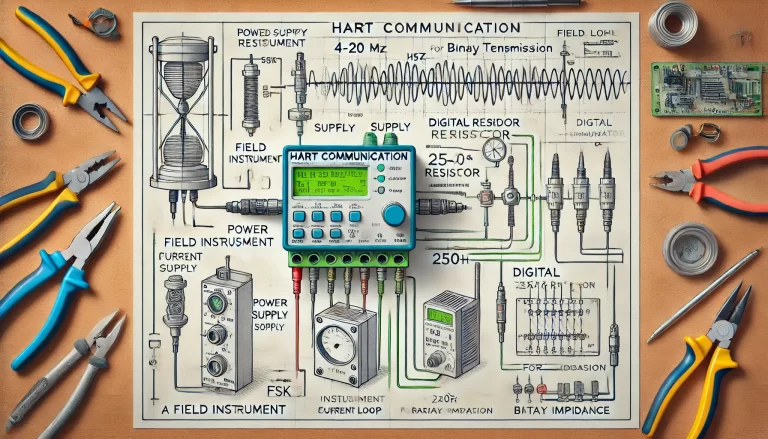

HART (Highway Addressable Remote Transducer) communicators play an essential role in industrial process control by facilitating two-way digital communication over 4-20 mA current loops. These devices are widely used for configuration, diagnostics, and maintenance of field instruments. One notable requirement when using a HART communicator is sometimes having to include a 250Ω resistor in series with the current loop. This article explains why this resistor is needed and how it supports proper HART communication.

The Basics of HART Communication

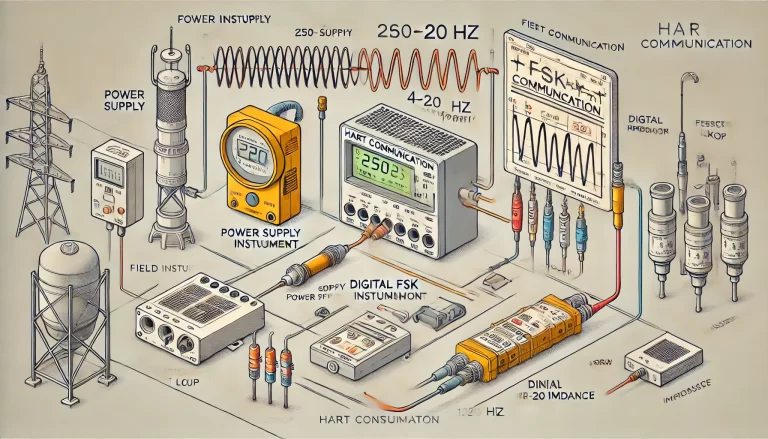

HART communication operates by superimposing digital signals on top of the standard 4-20 mA analog current loop. This allows digital data, such as configuration settings or diagnostic information, to be transmitted without disrupting the underlying analog signal used for process control.

The HART protocol uses a Frequency Shift Keying (FSK) technique, with two specific frequencies representing binary 1 and 0. These frequencies are 1200 Hz for a logical ‘1’ and 2200 Hz for a logical ‘0’. The protocol requires that the current loop can detect these frequency shifts accurately to facilitate clear communication.

The Role of Impedance in HART Communication

For HART communication to function correctly, the current loop must have sufficient impedance to enable the detection of the superimposed high-frequency signal. The standard requirement is that the total loop impedance should fall within the range of 230Ω to 1100Ω. This impedance range ensures that the FSK signal can be transmitted and received clearly by both the HART communicator and the field device.

In many practical scenarios, the existing impedance of the current loop—which includes the internal resistance of the power supply and field instrument—may not meet the minimum threshold of 230Ω. This is where the 250Ω resistor comes into play.

Why a 250Ω Resistor is Essential

Ensuring Minimum Loop Impedance: The 250Ω resistor helps to elevate the total impedance of the current loop to meet the HART protocol’s minimum requirement. Without this resistor, the impedance might be too low, leading to weak or unreliable communication. By adding a 250Ω resistor, the loop gains sufficient impedance to support the high-frequency signals used for HART communication.

Stability of High-Frequency Signal Detection: The presence of a 250Ω resistor enhances the ability of the HART communicator to detect and differentiate the 1200 Hz and 2200 Hz frequencies. These high-frequency components are critical for the accurate interpretation of binary data transmitted in the HART protocol. With insufficient impedance, these frequency shifts may not be adequately received, leading to communication errors or failure.

Consistent Performance Across Devices: Different field instruments and power supplies have varying internal resistances, which can cause the total loop impedance to vary widely. The use of a 250Ω resistor standardizes the loop’s impedance, helping to ensure consistent performance regardless of variations in the components of the loop.

How to Implement the 250Ω Resistor

When connecting a HART communicator to a current loop, the 250Ω resistor should be placed in series with the loop, typically between the power supply and the field instrument or between the communicator and the loop. This simple step helps maintain reliable communication and supports the overall stability of the system.

Important Note: The placement of the resistor should not disrupt the normal operation of the analog signal. Proper care should be taken to ensure that the loop remains operational while enabling HART communication.

Conclusion

In summary, the inclusion of a 250Ω resistor in a HART communication loop is vital for maintaining the necessary impedance required by the protocol. It ensures that the high-frequency signals representing digital data can be transmitted and detected effectively. By understanding and properly implementing this requirement, users can achieve stable, reliable communication between HART communicators and field instruments, supporting efficient process control and diagnostics in industrial settings