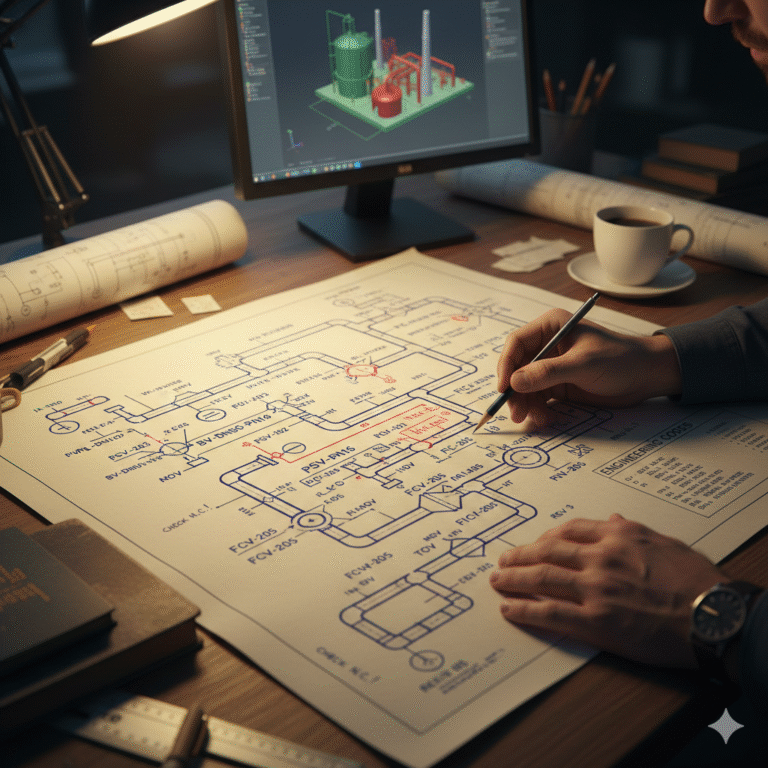

When engineers first look at a piping or P&ID drawing, one thing becomes immediately noticeable:

there are not many words, but there are many letter combinations.

These letters are what we commonly call valve and piping codes.

At first glance, they may look complicated, but in reality, they are simply a compact way of expressing technical information.

1. What Do Valve and Piping Codes Represent?

If we compare an engineering drawing to a map, then valve and piping codes act like road signs.

Instead of writing full equipment names, codes are used to quickly indicate:

what type of equipment it is

what function it performs in the system

its general size or pressure class

Once this concept is understood, reading these codes becomes much more intuitive and far less intimidating.

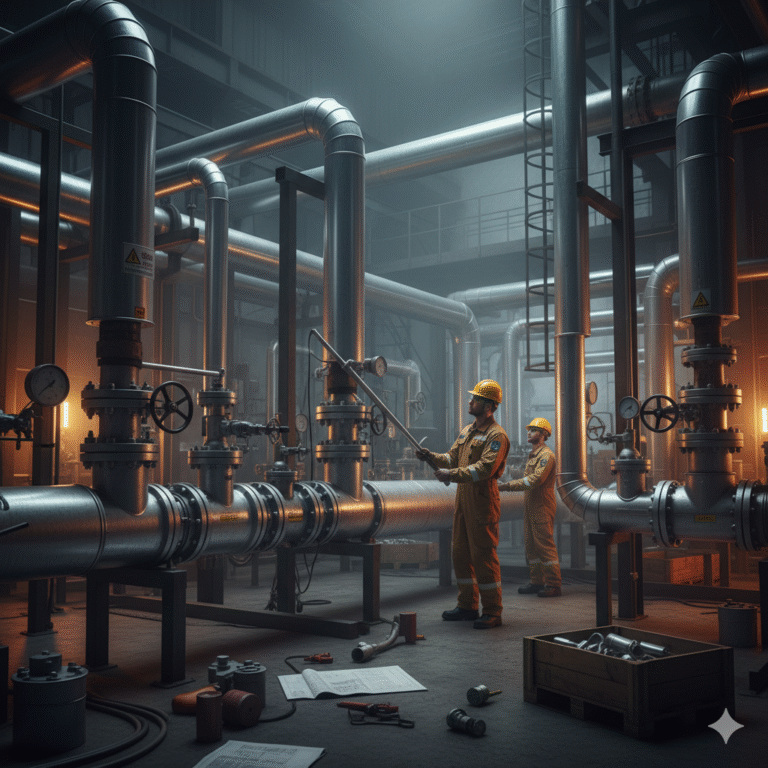

2. Common Valve Codes

Valves appear frequently in process systems, especially isolation valves, which usually represent the largest quantity in a piping network.

Isolation and Shut-Off Valves

These valves are mainly used to isolate pipelines or equipment:

GV – Gate Valve

DV – Globe Valve

BV – Ball Valve (in some projects, BV may also be used for butterfly valves; always follow project specifications)

SV – Plug Valve

When these codes appear on drawings, they typically indicate isolation points within the system.

Control and Regulating Valves

When the code includes CV, the function changes significantly:

CV – Control Valve

PCV – Pressure Control Valve

TCV – Temperature Control Valve

FCV – Flow Control Valve

LCV – Level Control Valve

These valves are normally installed at critical operating positions.

They act as the “regulating center” of the process and are essential for maintaining stable operating conditions.

Safety and Protection Valves

When safety-related codes appear, special attention is required:

PSV – Pressure Safety Valve

PRV – Pressure Reducing / Regulating Valve

RV – Relief Valve

BDV – Blowdown Valve

These valves are directly related to system protection and design limits.

Their locations and set parameters are critical for overall plant safety.

Check and Direction Control Valves

These valves prevent reverse flow and are commonly installed downstream of pumps or compressors:

NRV – Non-Return Valve (Check Valve)

DCV – Dual Plate Check Valve

Actuation-Related Codes

These codes describe how a valve is operated:

MOV – Motor Operated Valve

AOV – Air Operated Valve

SOV – Solenoid Operated Valve

SDV – Shutdown Valve

They are often used in combination with main valve codes and are closely related to automation and control systems.

3. Piping Codes

Compared with valves, piping codes focus more on describing the function of the pipeline itself.

Medium-Based Piping Identification

Common examples include:

PW – Process Water

CW – Cooling Water

FW – Feed Water

DW – Drain Water

SW – Sewage Water

IA – Instrument Air

PA – Plant / Process Air

These codes allow engineers to quickly identify the service of a pipeline.

System Function Classification

PL – Process Line

HL – Hot Utility Line

CL – Cooling Line

FL – Fuel Line

VL – Vent Line

When viewed together, these identifiers provide a clear understanding of the pipeline’s role within the process system.

Common Pipe Size and Rating Designations

DN – Nominal Diameter

PN – Nominal Pressure

SCH – Pipe Schedule (wall thickness)

STD / XS / XXS – Standard / Extra Strong / Double Extra Strong

Typical structure example:

Pipeline Code + DN + PN + Material

(exact sequence depends on project specifications)

Additional Identification Marks

N.O. – Normally Open

N.C. – Normally Closed

MAN – Manual

AUTO – Automatic

INS – Insulated

HT – Heat Traced

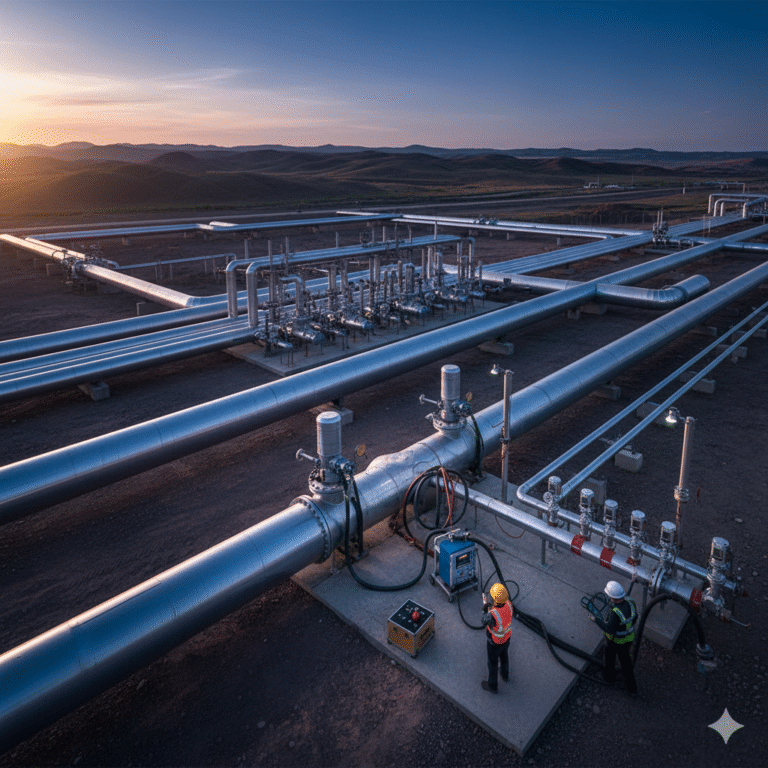

4. The Importance of Numbers in Tag Codes

Letters define the function, while numbers define the capacity.

For example:

BV–DN50–PN16

Means:

Ball Valve

Nominal Diameter 50

Nominal Pressure 16

Another example:

PW–PL–DN100

Indicates:

Process Water

Process Line

Nominal Diameter 100

Even without additional documentation, these codes already provide essential installation and selection information

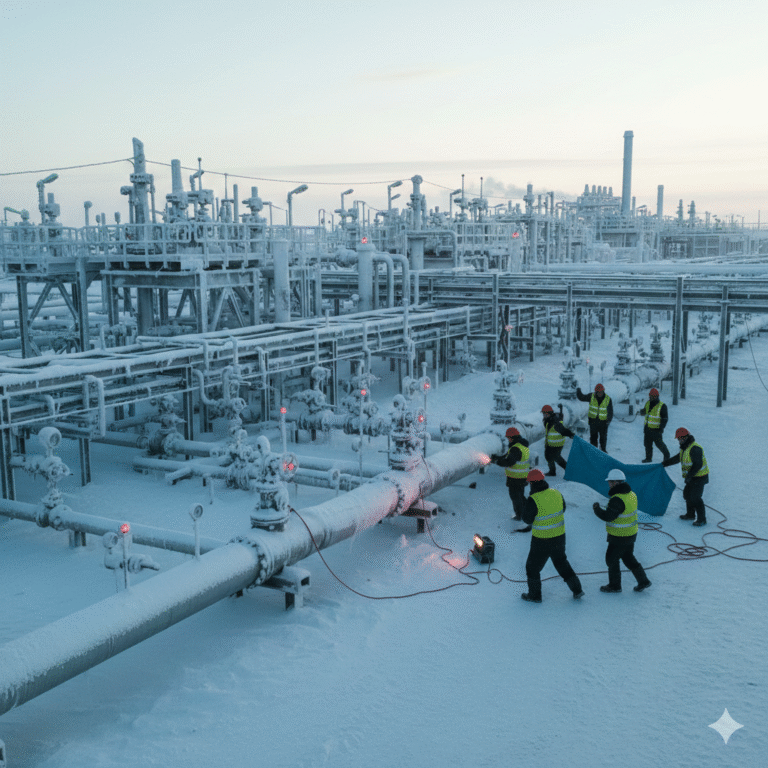

5. Always Read the Codes as a Complete Set

Valve tags and piping codes should never be interpreted separately.

For example:

PW–PL–DN100 + BV

This indicates:

Process water service

Process pipeline

DN100 size

Equipped with a ball valve

From this information alone, engineers can already visualize the physical configuration of the pipeline.

6. Understanding, Not Memorizing

Valve and piping codes are rarely meant to be memorized mechanically.

With sufficient exposure to drawings, engineers naturally begin to associate codes with real system scenarios.

At that point, letters are no longer abstract symbols — they become a concise technical language describing actual process conditions.

In real engineering projects, final interpretation should always follow the project specifications and the P&ID legend provided by the design institute.