Pressure sensors are among the most widely used devices in industrial applications. They are essential for automation and monitoring across industries such as hydropower, transportation, aerospace, military, petrochemicals, oil fields, power generation, and building automation. This article introduces the working principles of four common types of pressure sensors.

1. Piezoresistive Pressure Sensors

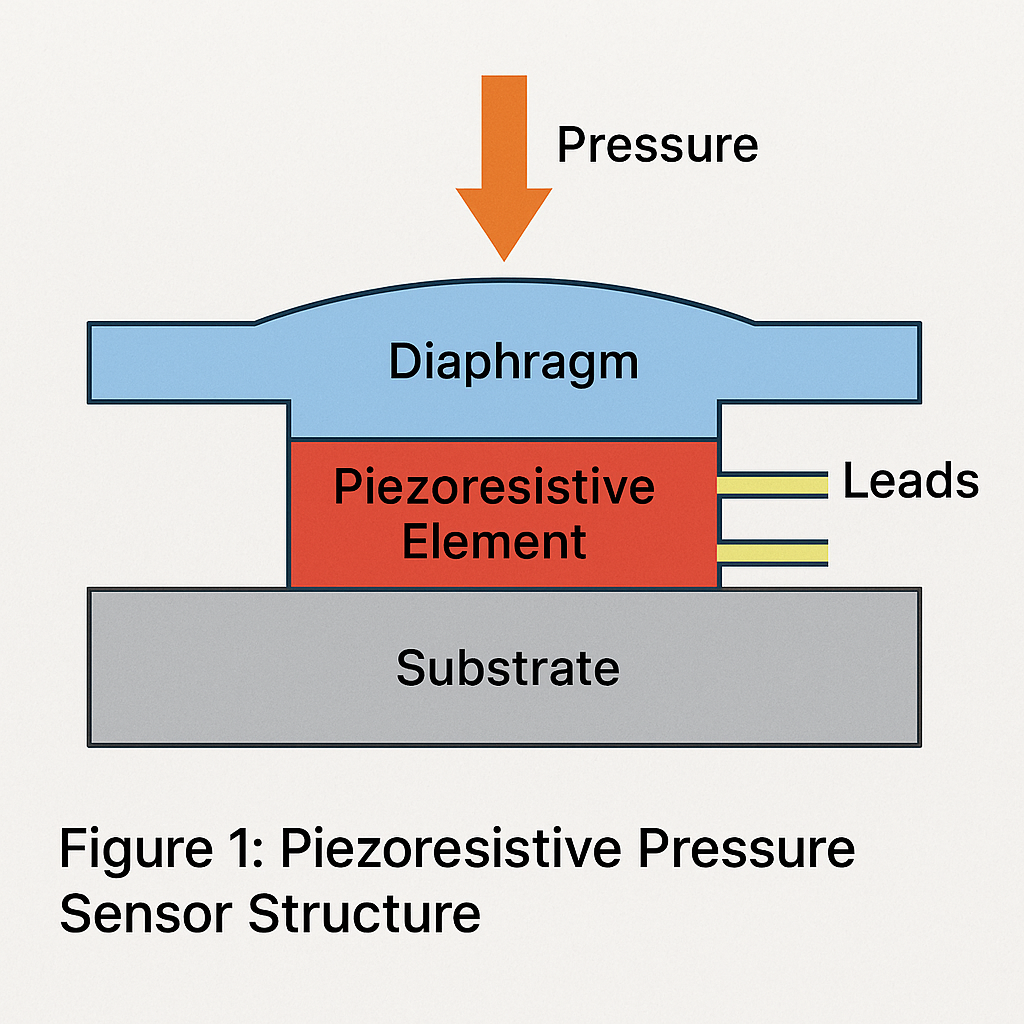

Working Principle: Piezoresistive pressure sensors use silicon wafers as elastic sensing elements. Through integrated circuit diffusion techniques, resistors are formed on the diaphragm to create a Wheatstone bridge. When external pressure is applied to the diaphragm, the resistance of the semiconductor changes due to the piezoresistive effect, causing an output voltage variation in the bridge. This voltage change is directly proportional to the applied pressure.

Advantages:

High sensitivity and accuracy

Compact structure

Wide measuring range

Applications:

Industrial process control

Medical devices

Hydraulic systems

2. Piezoelectric Pressure Sensors

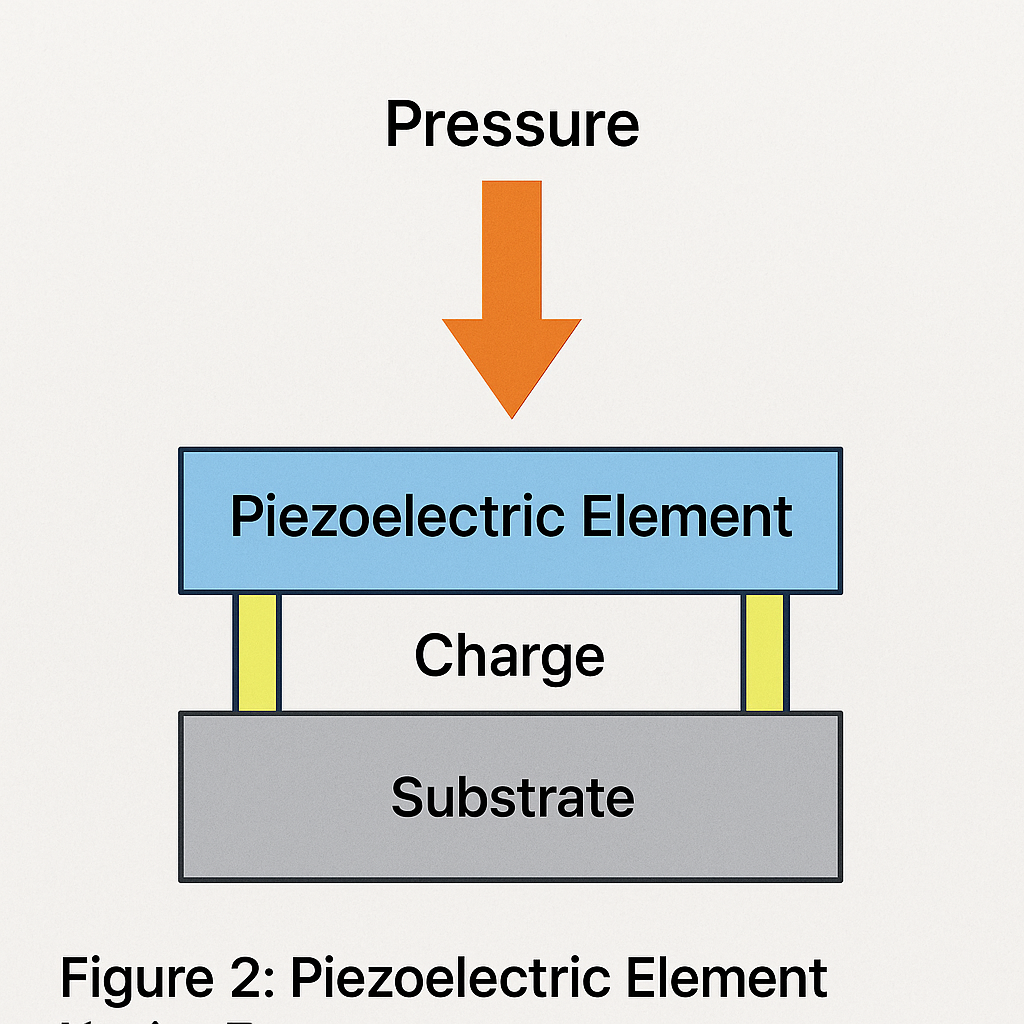

Working Principle: These sensors rely on the piezoelectric effect, where certain materials generate an electric charge when mechanically stressed. The applied pressure causes deformation of the crystal or ceramic element, resulting in a voltage output that can be measured and correlated to the pressure.

Advantages:

High natural frequency

Excellent for dynamic pressure measurements

Good performance in harsh environments

Limitations:

Cannot measure static pressure

Requires complex signal conditioning

Applications:

Engine monitoring

Explosion detection

Vibration analysis

3. Capacitive Pressure Sensors

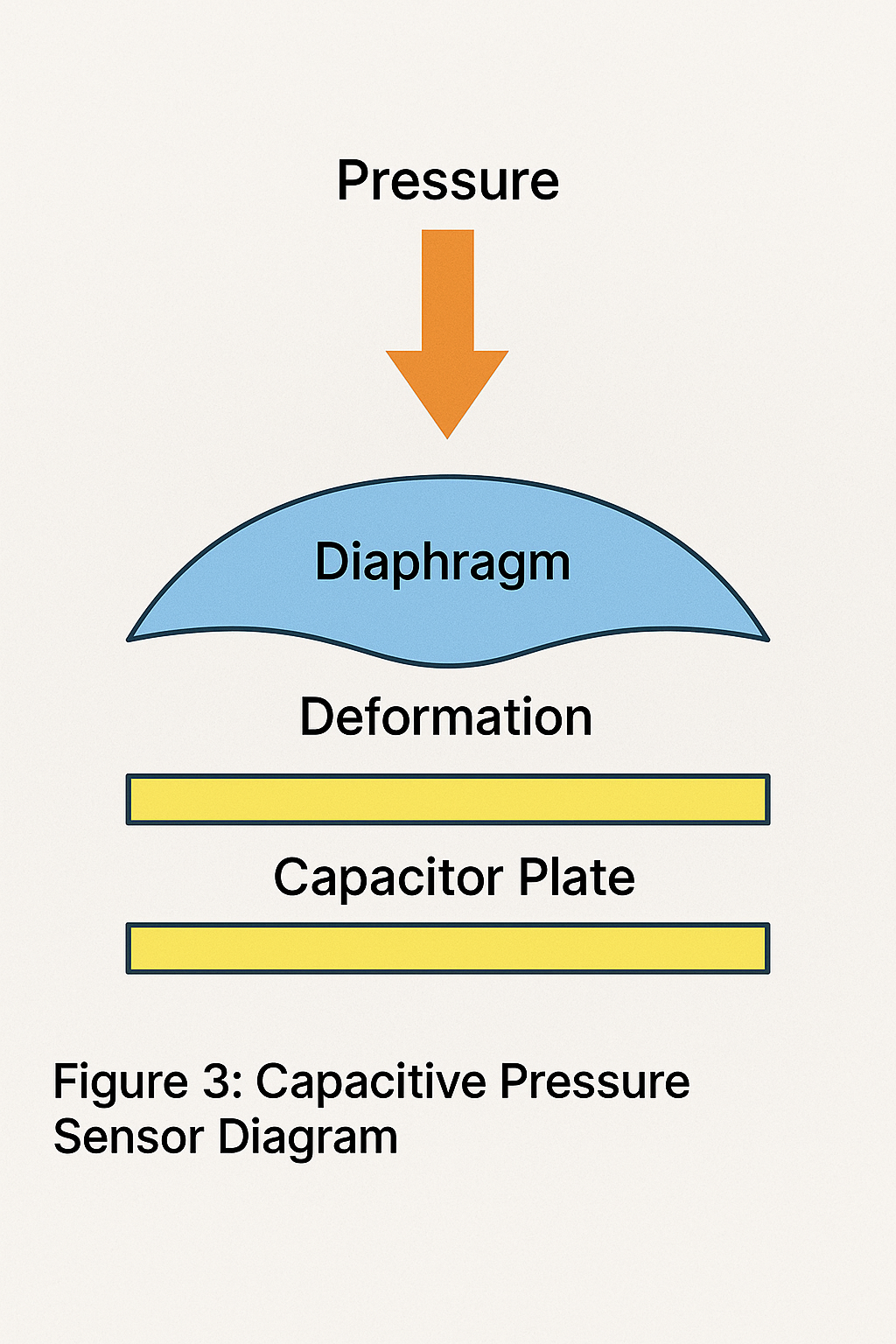

Working Principle: Capacitive pressure sensors use a flexible diaphragm as one plate of a capacitor. When pressure is applied, the diaphragm deforms, changing the distance between the plates and hence the capacitance. This change is converted into a corresponding voltage signal using electronic circuitry.

Types:

Single-capacitor sensors

Differential capacitive sensors

Advantages:

High sensitivity

Good linearity

Applications:

Low-pressure measurement

HVAC systems

Biomedical monitoring

4. Inductive Pressure Sensors

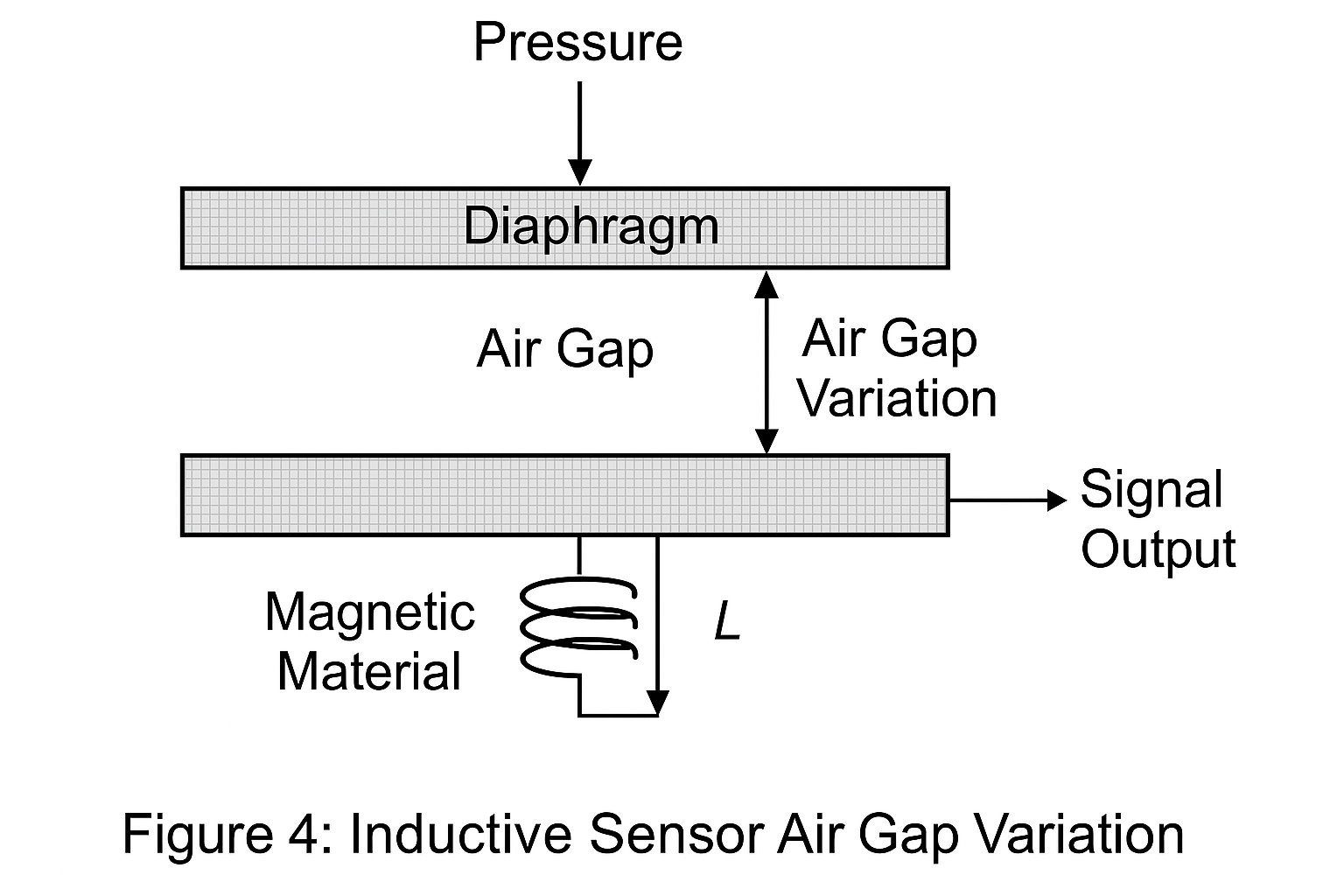

Working Principle: Inductive pressure sensors operate based on the change in inductance due to the movement of a magnetic core or diaphragm under pressure. The displacement changes the air gap in a magnetic circuit, affecting the coil’s inductance, which is then processed into an electrical signal.

Advantages:

High sensitivity

Wide measuring range

Limitations:

Not suitable for high-frequency dynamic environments

Applications:

Mechanical stress testing

Heavy-duty industrial systems

Summary Table: Sensor Type Comparison

| Sensor TypePrincipleKey AdvantagesMain Applications | |||

| Piezoresistive | Resistance change | Compact, accurate | Process control, hydraulics |

| Piezoelectric | Piezoelectric effect | Dynamic, rugged | Engines, explosions, vibrations |

| Capacitive | Capacitance variation | Sensitive, linear | Low-pressure, biomedical |

| Inductive | Inductance variation | Sensitive, wide range | Heavy-duty systems |

By understanding the working principles and application strengths of each type of pressure sensor, engineers and technicians can better select the optimal sensor type for specific process conditions and environmental requirements.