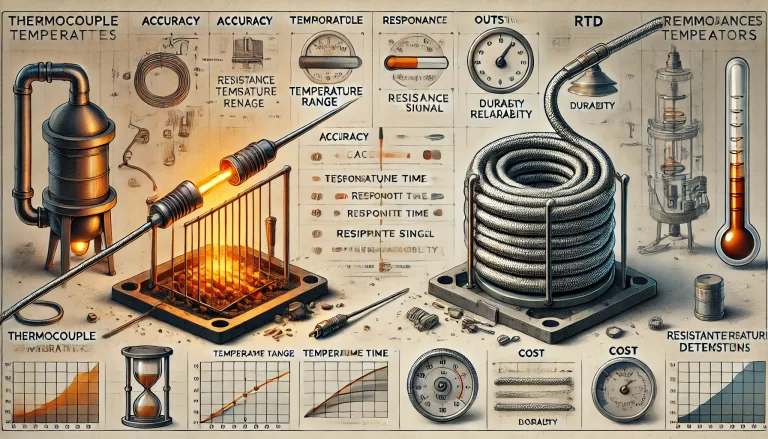

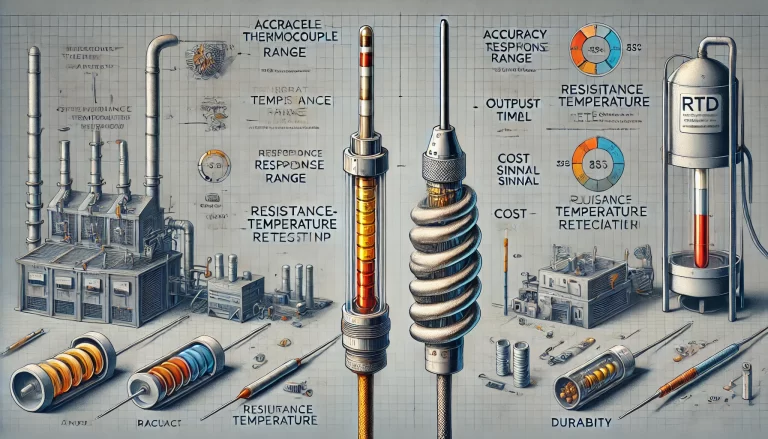

Thermocouples and Resistance Temperature Detectors (RTDs) are widely used temperature sensors with distinct characteristics and applications. Choosing the right sensor depends on the temperature range, environment, response time, and measurement precision. This article explores the differences, strengths, and use cases for thermocouples and RTDs in detail.

Thermocouples: Characteristics and Applications

1. Wide Temperature Range

Thermocouples are highly versatile and can measure extreme temperatures. They are suitable for environments ranging from as low as -200°C to as high as 1200°C or more, depending on the thermocouple type (e.g., Type K, J, or R). This makes them ideal for both cryogenic and high-temperature applications.

2. Fast Response Time

Thermocouples have a small thermal mass, enabling them to respond quickly to rapid temperature changes. This is critical in applications like gas turbines or combustion chambers, where temperatures fluctuate rapidly.

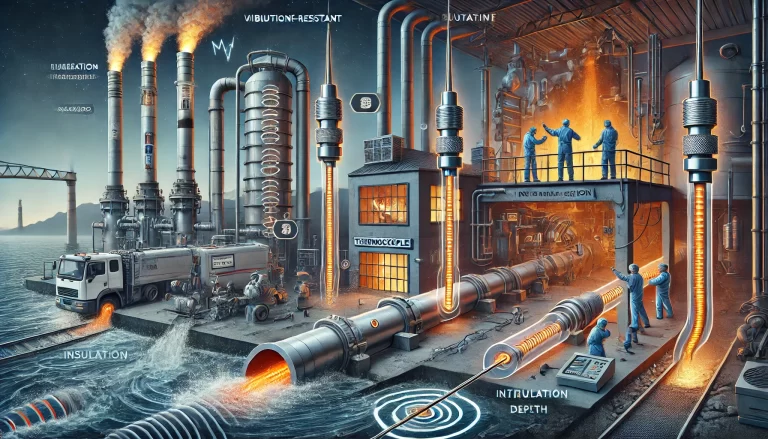

3. Robustness in Harsh Environments

Thermocouples are designed to withstand harsh operating conditions, including high pressure, high vibration, and corrosive atmospheres. For example:

- Industrial Furnaces: Thermocouples monitor high-temperature processes like steel or glass manufacturing.

- Engines and Turbines: Thermocouples track exhaust or internal temperatures in engines.

4. Compact Design for Point Measurements

Due to their small size, thermocouples are excellent for point-specific temperature measurements, especially where spatial precision is essential, such as in experimental setups or localized heating systems.

5. Electrical Output and Signal Transmission

Thermocouples generate a small voltage signal based on the Seebeck effect, making them suitable for long-distance signal transmission. However, this signal is prone to noise, requiring careful shielding and calibration.

Resistance Temperature Detectors (RTDs): Characteristics and Applications

1. High Measurement Accuracy

RTDs provide superior accuracy and repeatability compared to thermocouples, typically with an error margin as low as ±0.1°C. This precision makes RTDs ideal for laboratory and industrial applications requiring exact temperature control.

2. Optimal for Moderate Temperature Ranges

RTDs function best within the -200°C to 500°C range. This makes them well-suited for applications in HVAC systems, refrigeration, and general process control where extreme temperatures are not encountered.

3. Stability Over Time

RTDs rely on the change in electrical resistance of materials (commonly platinum) with temperature. The stability of platinum over time ensures that RTDs maintain their calibration for extended periods, making them ideal for long-term monitoring.

4. Resilience Against Electrical Noise

RTDs have stronger resistance to electrical interference, making them a better choice for environments with significant electromagnetic noise. This is particularly advantageous in industrial or urban areas.

5. Slower Response Time

Due to their larger thermal mass compared to thermocouples, RTDs respond more slowly to temperature changes. This can be a limitation in dynamic processes but is acceptable in steady-state environments.

Comparison of Thermocouples and RTDs

| Feature | Thermocouples | RTDs |

|---|---|---|

| Temperature Range | -200°C to 1200°C (or higher) | -200°C to 500°C |

| Measurement Accuracy | Medium | High |

| Response Time | Fast | Slow |

| Long-term Stability | Moderate | Excellent |

| Environmental Robustness | High (vibration, high pressure, etc.) | Moderate |

| Signal Strength | Low (voltage-based, prone to noise) | High (resistance-based, noise-resistant) |

| Cost | Generally lower | Generally higher |

When to Choose Thermocouples

- High-Temperature Applications:

- Industrial kilns, furnaces, and heat treatment processes.

- Dynamic Environments:

- Engines, gas turbines, and other systems with rapid temperature changes.

- Harsh or Corrosive Conditions:

- Chemical plants or metal processing industries.

- Cost-Conscious Projects:

- Large-scale deployments where cost is a concern.

When to Choose RTDs

- Precision Measurement:

- Laboratory experiments or pharmaceutical manufacturing.

- Stable, Long-Term Monitoring:

- HVAC systems, food processing, and energy systems.

- Electrically Noisy Environments:

- Urban installations or heavy industrial areas.

- Moderate Temperature Ranges:

- Situations where the temperature remains below 500°C.

Real-World Scenarios

- Thermocouple in a Glass Manufacturing Plant:

- A Type K thermocouple monitors the molten glass temperature, ensuring consistency during shaping and solidifying at temperatures above 1000°C.

- RTD in a Food Processing Facility:

- An RTD sensor maintains precise temperature control for pasteurization, where long-term stability and accuracy are critical.

Conclusion

Thermocouples and RTDs each have unique strengths and limitations. For applications requiring high temperatures, rapid response, or durability in harsh environments, thermocouples are the go-to choice. Conversely, RTDs are preferred for their accuracy, stability, and noise resistance in moderate temperature ranges.

Choosing between the two depends on the specific requirements of the application. When in doubt, consulting with an instrumentation expert can help determine the best sensor for your needs.