Steam is one of the most widely used energy carriers in industrial processes. From food processing and pharmaceuticals to chemical plants, paper mills, and power generation, steam plays a crucial role as both a heat transfer medium and a source of mechanical energy.

This article provides a system-level overview of how a steam and condensate system works — including its core components, operational logic, and energy management strategies — helping engineers and technical beginners build a clear understanding of the overall system.

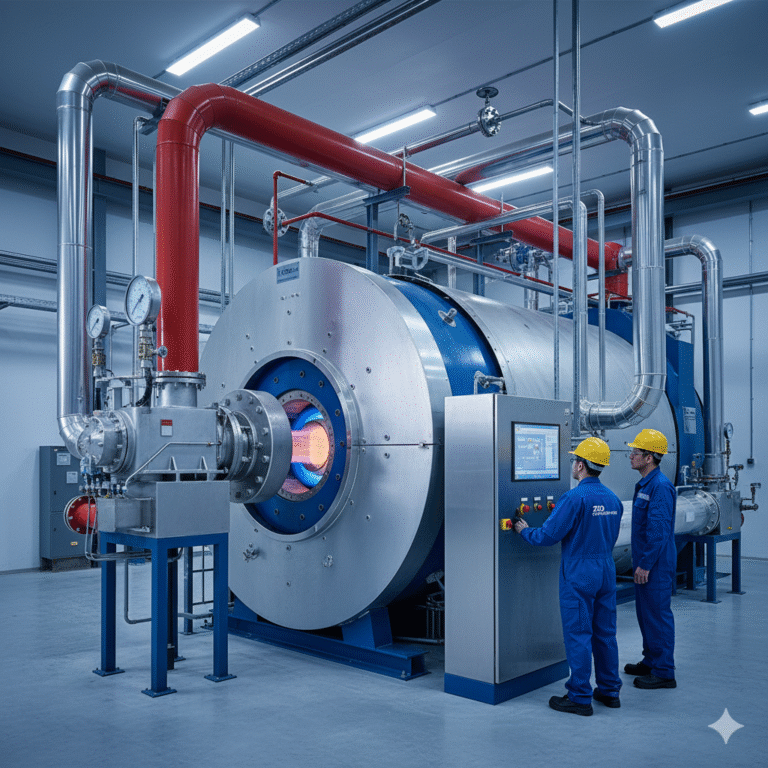

1. The Boiler House – The Heart of the Steam System

1.1 Basic Principle of Steam Generation

The boiler is the energy core of the entire steam system. Its main function is to convert the chemical energy of fuel into thermal energy in the form of steam.

Modern fire-tube boilers use burners to produce high-temperature flue gas, which transfers heat through multiple passes of tubes to generate saturated steam.

When the internal pressure and steam generation rate reach equilibrium, the boiler operates in a stable condition. High-pressure steam has higher energy density and smaller volume, which allows for efficient transportation and smaller pipe diameters.

Maintaining stable pressure is essential — because steam pressure directly determines its temperature, and both are key to process consistency and product quality.

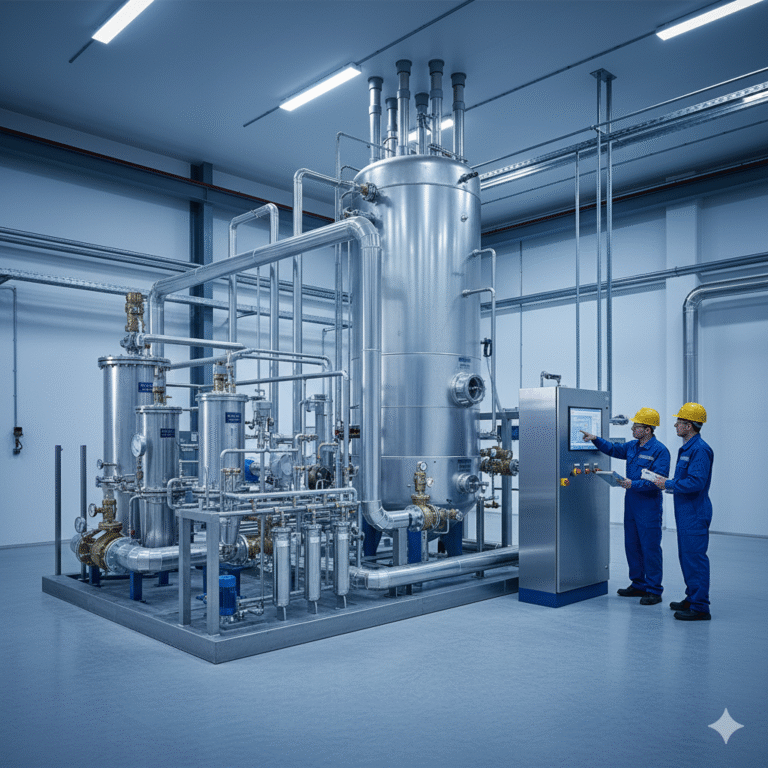

2. The Three Protectors of the Boiler

2.1 Feedwater System

The quality and temperature of boiler feedwater directly affect the system’s efficiency and service life.

Untreated tap water can cause scaling, corrosion, and reduced heat transfer efficiency. Therefore, chemical water treatment and deaeration are essential.

Feedwater tanks often use steam injection heating to remove dissolved oxygen, preventing corrosion right from the source.

2.2 Blowdown System

During continuous operation, dissolved solids and suspended impurities gradually accumulate in the boiler water. To maintain stable operation, regular blowdown is required.

With a TDS automatic control system, sensors monitor water quality in real time and automatically discharge part of the boiler water when solids exceed the threshold. This ensures chemical balance inside the boiler and reduces manual maintenance.

2.3 Level Control System

Abnormal water levels are one of the most common causes of boiler accidents.

Low level: May cause overheating or tube rupture.

High level: May lead to carryover of water into the steam lines, contaminating the process.

Modern boilers use automatic level control and dual alarm systems, combining sensors and float valves to maintain precise and safe water levels.

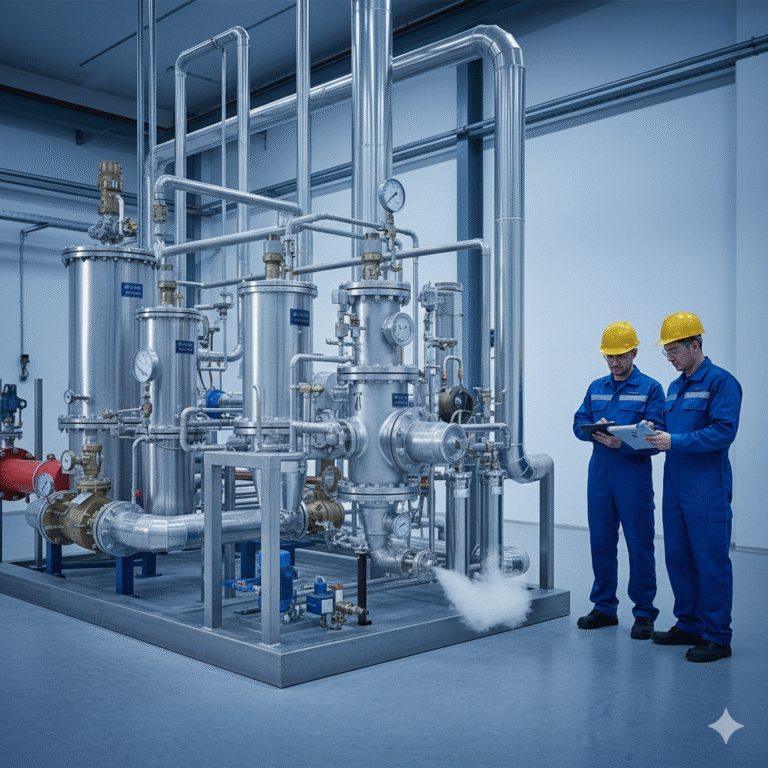

3. Steam Distribution and Quality Control

3.1 Driving Force of Steam Flow

As steam flows through the piping network, it condenses into water, causing a volume reduction that creates a natural pressure difference. This pressure gradient drives the steam forward.

High-pressure steam is transmitted efficiently through smaller pipes, and pressure-reducing valves are used to adjust to the required process pressure.

3.2 Ensuring Steam Quality

Steam quality has a direct impact on product quality and process stability.

To ensure clean and dry steam, pipelines are equipped with:

Filters – to remove solid particles

Steam separators – to remove entrained water droplets

Insulation layers – to minimize heat loss and improve energy efficiency

4. Condensate Recovery and Energy Efficiency

When steam releases its latent heat within equipment, it condenses into water — called condensate — which still contains significant sensible heat.

Condensate can be classified as:

Recoverable: Clean and hot, suitable for returning to the feedwater tank.

Non-recoverable: Contaminated and discharged directly.

To overcome backpressure or vacuum in equipment, mechanical or electric condensate pumps are used to return hot condensate to the boiler system, creating a closed-loop energy cycle.

5. Steam Utilization and Flow Control

Common steam-using equipment includes:

Jacketed kettles – for heating in food processing

Autoclaves – for sterilization and curing

Heat exchangers and coils – for HVAC or process heating

Corrugating machines and vulcanizers – in paper and rubber industries

In these systems, precise control of steam flow and temperature is critical.

A typical control loop consists of sensors, controllers, and actuators, automatically adjusting the control valve to maintain stable process conditions.

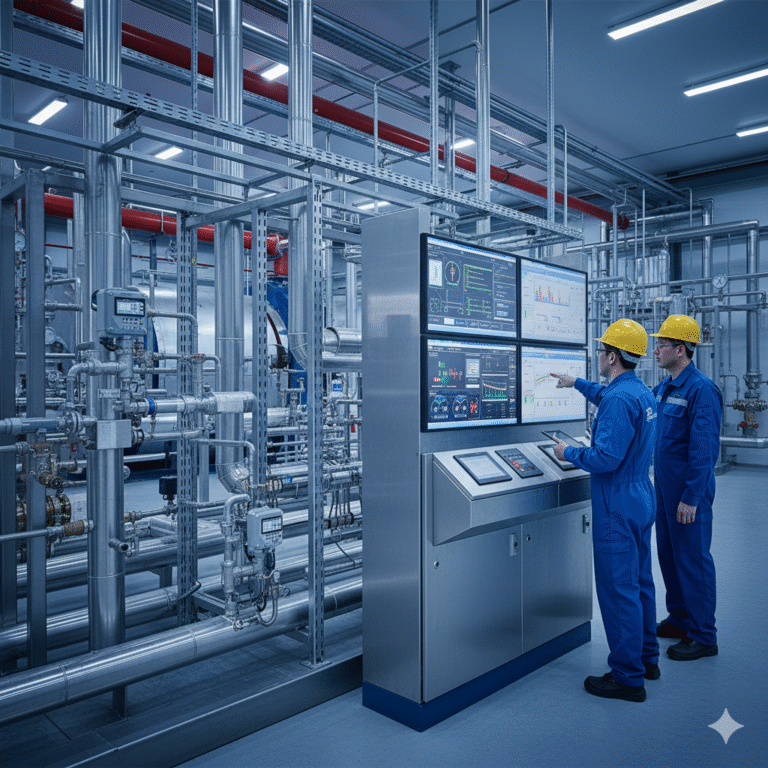

6. Energy Management and Monitoring

With the growing emphasis on energy saving and carbon reduction, modern factories are integrating digital monitoring systems to manage steam usage efficiently.

By installing steam flow meters, pressure transmitters, and condensate temperature sensors, operators can:

Monitor real-time steam consumption

Evaluate equipment efficiency

Identify energy losses

Support optimization and cost reduction

This transformation — from “black-box operation” to “data-driven management” — is a defining trend in industrial steam systems.

7. Conclusion

A steam and condensate system is a highly integrated energy ecosystem, where every stage — from combustion to condensation, from water treatment to monitoring — affects the system’s efficiency and safety.

Understanding the system’s logic is not only the first step to mastering steam engineering, but also a key step toward energy conservation, carbon reduction, and intelligent plant management.