Introduction

Thermocouples are widely used temperature sensors that operate based on the thermoelectric effect, where a voltage is generated when two dissimilar metals are joined and exposed to a temperature gradient. Due to their reliability, wide temperature range, and rapid response time, thermocouples are extensively used in industrial applications, laboratories, and scientific research. However, different types of thermocouples have distinct properties, making them suitable for specific environments and applications.

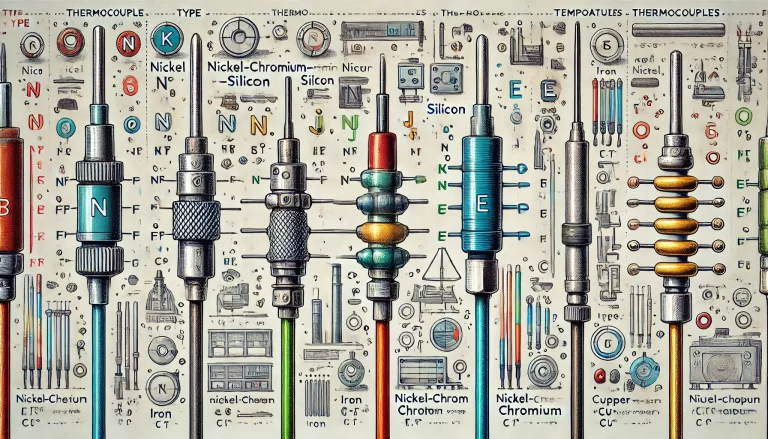

This article explores seven common types of thermocouples (K, J, T, E, N, S, and B), detailing their characteristics, advantages, and typical applications.

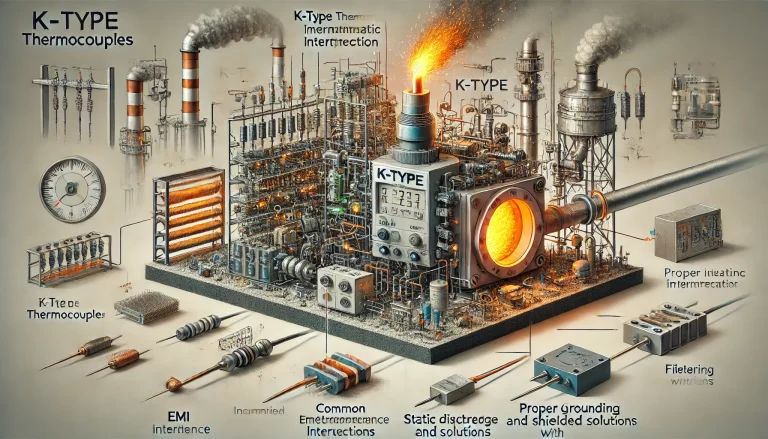

1. K-Type Thermocouple (Nickel-Chromium / Nickel-Silicon, Ni-Cr/Ni-Si)

Temperature Range: -200°C to 1372°C (-328°F to 2501°F)

Sensitivity: Approximately 41 µV/°C

Features:

Affordable and widely available

Excellent stability and longevity

Performs well in oxidizing and inert atmospheres but degrades in reducing environments

Susceptible to high-temperature drift over extended use

Applications:

Industrial temperature measurement

Metal processing

Gas turbines

Scientific research

2. J-Type Thermocouple (Iron / Copper-Nickel, Fe/Cu-Ni)

Temperature Range: -210°C to 1200°C (-346°F to 2192°F)

Sensitivity: Approximately 55 µV/°C

Features:

High accuracy in lower temperature applications

Good performance in vacuum, oxidizing, and reducing atmospheres

Prone to oxidation in humid environments, limiting its lifespan

Applications:

Plastic and rubber manufacturing

Food processing

General-purpose industrial heating

3. T-Type Thermocouple (Copper / Copper-Nickel, Cu/Cu-Ni)

Temperature Range: -200°C to 400°C (-328°F to 752°F)

Sensitivity: Approximately 43 µV/°C

Features:

High accuracy and stability at low temperatures

Excellent corrosion resistance in moist environments

Works well in cryogenic applications

Applications:

Medical and pharmaceutical industries

Refrigeration and cryogenics

Food storage and processing

4. E-Type Thermocouple (Nickel-Chromium / Copper-Nickel, Ni-Cr/Cu-Ni)

Temperature Range: -200°C to 1000°C (-328°F to 1832°F)

Sensitivity: Approximately 68 µV/°C (highest among base metal thermocouples)

Features:

High sensitivity and good accuracy

Performs well in low-temperature environments

Strong resistance to oxidation

Applications:

Aerospace and avionics

Industrial and scientific temperature measurement

High-precision laboratory applications

5. N-Type Thermocouple (Nickel-Chromium-Silicon / Nickel-Silicon-Magnesium, Ni-Cr-Si/Ni-Si-Mg)

Temperature Range: -200°C to 1300°C (-328°F to 2372°F)

Sensitivity: Approximately 39 µV/°C

Features:

Enhanced stability and oxidation resistance compared to K-type

Reduced drift over prolonged exposure to high temperatures

Better performance in high-radiation environments

Applications:

Aerospace and nuclear industries

High-temperature research

Industrial furnaces and kilns

6. S-Type Thermocouple (Platinum-Rhodium 10% / Platinum, Pt-Rh10/Pt)

Temperature Range: 0°C to 1600°C (32°F to 2912°F)

Sensitivity: Approximately 10 µV/°C

Features:

Extremely high accuracy and stability

Expensive due to the use of platinum and rhodium

Performs well in oxidizing atmospheres but degrades in reducing environments

Applications:

Glass and ceramic industries

High-precision metallurgy

Laboratory and scientific research

7. B-Type Thermocouple (Platinum-Rhodium 30% / Platinum-Rhodium 6%, Pt-Rh30/Pt-Rh6)

Temperature Range: 600°C to 1800°C (1112°F to 3272°F) (produces minimal voltage below 600°C)

Sensitivity: Approximately 5 µV/°C

Features:

Suitable for extremely high-temperature applications

Very stable at high temperatures with minimal drift

Ineffective for low-temperature measurement due to its low thermoelectric voltage below 600°C

Applications:

High-temperature industrial processes

Glass and steel manufacturing

Kilns and furnaces

Conclusion

Choosing the right thermocouple type depends on several factors, including the required temperature range, sensitivity, stability, and environmental conditions. Base metal thermocouples (K, J, T, E, N) are cost-effective and widely used in industrial and scientific applications, while noble metal thermocouples (S, B) are more expensive but offer superior stability and precision at high temperatures.

Understanding the characteristics of each thermocouple type helps engineers and technicians select the most suitable sensor for their specific applications, ensuring accurate and reliable temperature measurement in various industries.