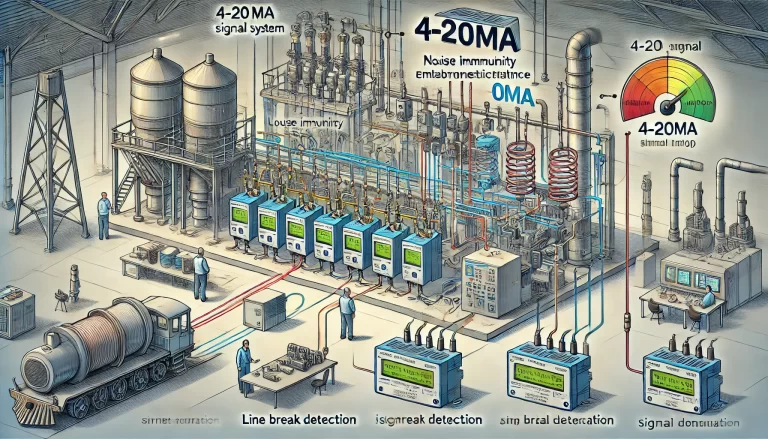

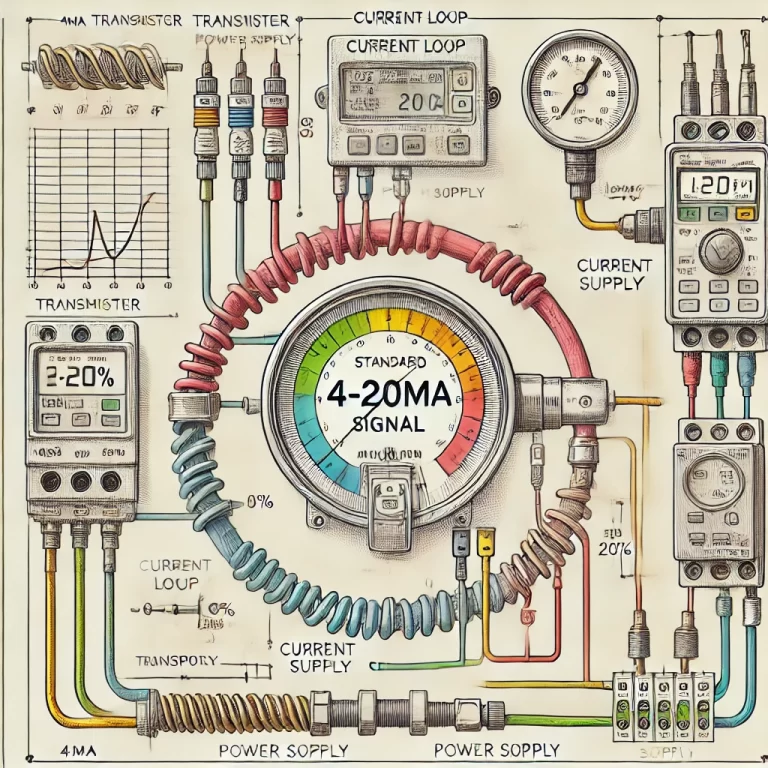

In industrial process automation, the 4-20mA signal is one of the most widely used standards for transmitting analog data from sensors and transmitters to control systems. This signal range, where 4mA typically represents the zero or minimum of a process variable and 20mA represents the maximum, allows control systems to monitor and manage a wide range of variables, from temperature and pressure to flow and level. However, for operators and control systems to reliably detect and handle any errors in the signal, there must be a clear standard for how fault conditions are communicated. This is where the NAMUR NE43 standard comes in.

What is NAMUR NE43?

NAMUR, a European association of process industry users of automation technology, created the NE43 standard to define specific ranges within the 4-20mA signal spectrum for indicating both valid measurement data and fault conditions. The purpose of NAMUR NE43 is to enable process control systems to distinguish between normal operating values and errors or faults in measurement devices.

Key Ranges Defined by NAMUR NE43

The NAMUR NE43 standard specifies different ranges within the 4-20mA signal as follows:

Normal Operating Range (3.8mA to 20.5mA):

- The range between 4mA and 20mA typically represents the linear measurement of a process variable, with 4mA indicating the minimum (or zero) and 20mA representing the maximum.

- NAMUR NE43 extends this normal range slightly, to include values from 3.8mA to 20.5mA. This allows for minor variations or noise without triggering a fault condition, as signals slightly below or above the standard 4-20mA range may still be legitimate measurements rather than faults.

- Within this range, operators can interpret the signal as valid and corresponding to the measured variable.

2. Fault Detection Ranges:

- Low Fault Condition (<3.6mA): Signals below 3.6mA indicate a fault condition, which may be caused by issues such as a broken wire, an open circuit, or a failure in the sensor or transmitter. This ensures that the control system can detect a loss of signal as a clear sign of malfunction.

- High Fault Condition (>21mA): Signals above 21mA are also considered a fault condition, potentially due to short circuits, overcurrent situations, or other hardware issues in the transmitter. When the current exceeds 21mA, this alerts the control system that the device has likely malfunctioned.

3. Warning or Alert Range (3.6-3.8mA and 20.5-21mA):

- In addition to the core fault ranges, NAMUR NE43 specifies two “caution” areas: 3.6-3.8mA and 20.5-21mA. These ranges, although not necessarily faults, provide a buffer zone where the measurement might be approaching a fault condition.

- By monitoring these alert ranges, control systems can give early warnings, allowing operators to investigate potential issues before they escalate into complete device failures.

Why NAMUR NE43 Matters in Process Control

The NAMUR NE43 standard enhances reliability and safety in industrial processes in several ways:

- Clear Distinction of Faults: By defining specific fault thresholds, NAMUR NE43 helps control systems unambiguously identify when a transmitter is no longer providing valid data, allowing operators to take prompt corrective actions.

- Increased Safety and Efficiency: Early fault detection reduces downtime and increases system safety, as control systems can automatically switch to a safe state if they detect an out-of-range signal. This is especially crucial in industries where precise measurement is essential to avoid hazardous situations, such as in chemical processing or power generation.

- Diagnostic Capability: With the defined fault ranges, diagnostic systems in advanced controllers or safety systems can automatically alert technicians to specific device or connection issues, improving maintenance schedules and reducing unexpected failures.

Practical Implementation of NAMUR NE43

To implement NAMUR NE43 effectively, manufacturers of transmitters and control systems design their devices to recognize these defined signal ranges and act accordingly. Most programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems can be configured to recognize the NAMUR NE43 ranges and trigger appropriate alarms or corrective actions.

For example, if a temperature sensor sends a signal of 22mA, the DCS would interpret this as a fault condition, likely generating an alarm and potentially switching to a backup sensor if available. Likewise, if the signal drops to 3.4mA, the system would recognize an open circuit and generate a similar alarm.

Conclusion

The NAMUR NE43 standard plays a critical role in ensuring the robustness and safety of industrial automation by defining fault detection ranges in 4-20mA analog signals. By establishing a clear protocol for distinguishing between valid measurements and fault conditions, NAMUR NE43 enables faster detection of equipment issues, minimizes downtime, and enhances overall process safety. As such, it is an essential standard for any industry that relies on process control, from manufacturing and oil and gas to pharmaceuticals and food processing.

Understanding and implementing NAMUR NE43 can significantly improve system reliability, safeguard operations, and help maintain smooth and efficient industrial processes.