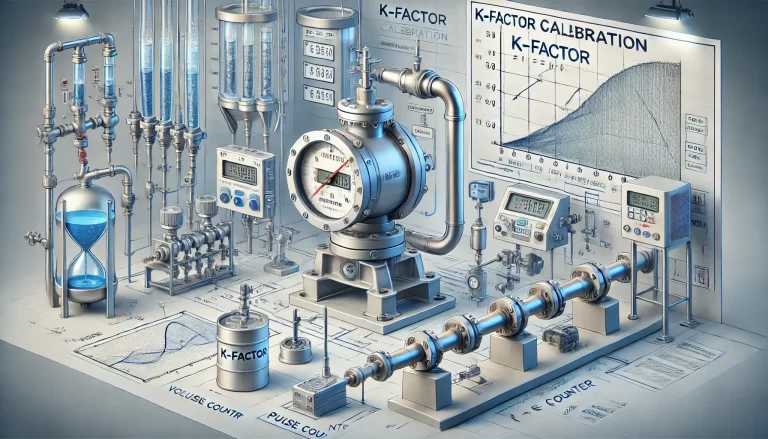

Flow meters are critical instruments used in various industries to measure the flow rate of fluids, gases, or vapors. Among their many calibration parameters, the K-factor stands out as an essential component. This article will delve into the concept of the K-factor, its significance, and how to calculate it accurately.

What is the K-Factor?

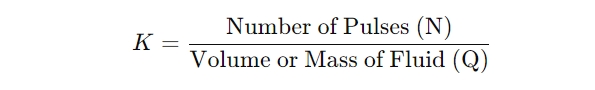

The K-factor is a calibration constant that defines the relationship between the flow meter’s output pulses and the actual flow rate of a fluid. Mathematically, it is expressed as:

The K-factor is typically measured in units like pulses per liter (PPL) or pulses per cubic meter (P/m³). It serves as a bridge between the raw electrical signal generated by the flow meter and the quantifiable flow data required by users.

Significance of the K-Factor

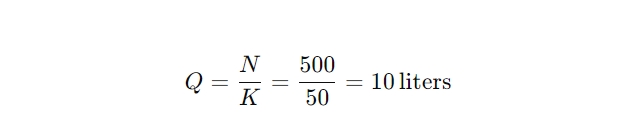

Conversion of Signals to Flow Rates: Flow meters output electrical pulses proportional to the flow rate. The K-factor converts these pulses into understandable units, such as liters per second or kilograms per minute.

For example, if a flow meter outputs 500 pulses and the K-factor is 50 PPL, the actual flow is:

2. Ensuring Measurement Accuracy: Since the K-factor is unique to each flow meter and its operating conditions, it allows for precise calibration, ensuring reliable measurements in diverse applications.

3. Adaptability to Changing Conditions: The K-factor can vary with factors such as fluid type, temperature, pressure, and flow rates. This adaptability is crucial for maintaining accuracy in dynamic environments.

Types of Flow Meters Utilizing the K-Factor

The K-factor is most commonly associated with:

- Turbine Flow Meters: These meters generate pulses as blades rotate in response to fluid flow.

- Vortex Flow Meters: Pulses are produced by vortices shed at a known frequency.

- Positive Displacement Flow Meters: Mechanical rotations are converted into electrical pulses.

How to Calculate the K-Factor

Accurate determination of the K-factor is critical for calibration and performance validation. The following steps outline the process:

1. Setup and Instrumentation

- Install the flow meter in a controlled test setup. Ensure the setup mimics actual operating conditions, including fluid type, temperature, and pressure.

- Use a reference measurement device such as a volumetric tank or a high-accuracy master flow meter to establish the actual flow rate.

2. Record Data

- Operate the flow meter and monitor its pulse output using a pulse counter or data acquisition system.

- Simultaneously, measure the corresponding fluid volume or mass over a specific time interval using the reference device.

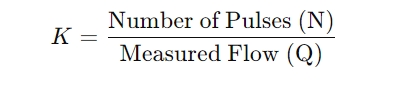

3. Calculate the K-Factor

- Use the recorded data to calculate the K-factor:

4. Repeat Measurements

- Conduct multiple measurements at different flow rates to ensure consistency.

- Average the K-factor values or establish a flow-rate-dependent curve if the K-factor varies significantly across the meter’s range.

5. Generate a Calibration Curve

- Plot the K-factor against flow rate. In many cases, the K-factor remains constant over a specific range but may deviate at the extremes. Documenting this relationship helps in applying corrections during operation.

Factors Affecting the K-Factor

Fluid Properties: Variations in viscosity, density, or composition can alter the meter’s response, affecting the K-factor.

Installation Conditions: Pipe alignment, flow disturbances, or air entrainment can lead to measurement inaccuracies.

Environmental Factors: Temperature and pressure changes may impact the physical characteristics of the fluid and the meter’s performance.

Wear and Tear: Over time, mechanical components in flow meters may degrade, causing the K-factor to drift.

Applications of the K-Factor

The K-factor is widely used in industries such as:

- Oil and Gas: For precise measurement of hydrocarbon flow in pipelines.

- Water Treatment: To monitor water consumption and ensure regulatory compliance.

- Pharmaceuticals: For dosing and batching applications requiring high precision.

- Food and Beverage: To control ingredient proportions in manufacturing processes.

Tips for Accurate K-Factor Calibration

Use High-Quality Reference Instruments: The accuracy of the K-factor depends on the reliability of the reference flow measurement device.

Calibrate Under Real Operating Conditions: Ensure that calibration reflects the actual fluid and environmental conditions in which the meter will operate.

Periodically Verify and Adjust: Regular recalibration is essential to account for changes in the meter’s condition or the operating environment.

Minimize External Influences: Avoid turbulence or air bubbles in the fluid, as these can disrupt the meter’s pulse generation.

Conclusion

The K-factor is a cornerstone of flow meter calibration, translating raw pulse signals into actionable flow data. Accurate determination and regular verification of the K-factor are essential for ensuring the reliability of flow measurements across various applications. By understanding its calculation and factors influencing its accuracy, users can optimize flow meter performance and maintain high standards of operational efficiency.