1. Overview

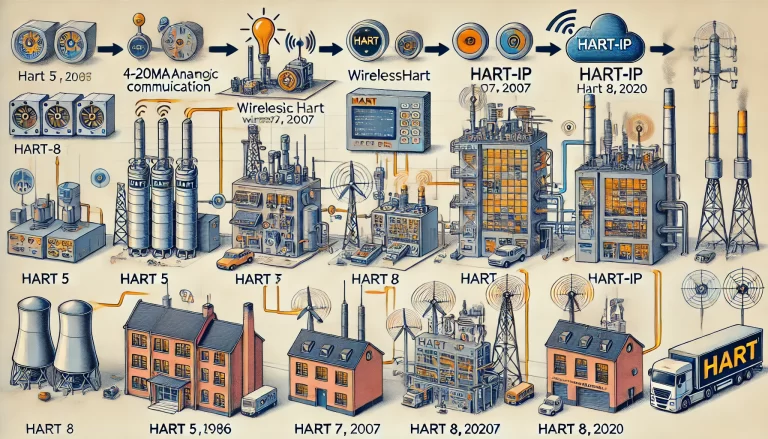

HART (Highway Addressable Remote Transducer) is a hybrid analog-digital communication protocol developed by Rosemount in the mid-1980s and released as an open standard in 1986. It is widely used in industrial process automation for enabling smart field devices to communicate over the same 4–20 mA analog signal wiring, combining conventional analog control with digital diagnostics and configuration.

HART communication employs Bell 202 Frequency Shift Keying (FSK), where a digital signal (typically ±0.5 mA) is superimposed on the standard 4–20 mA analog loop without interfering with the process signal.

2. Communication Principle

The key concept behind HART is simultaneous transmission of analog and digital signals:

Analog Signal (4–20 mA): Carries the primary process variable.

Digital Signal (FSK modulated): Transmits additional data such as device diagnostics, secondary variables, configuration parameters, and status information.

This hybrid system allows backward compatibility with legacy systems while providing access to digital intelligence.

3. HART Command Categories

HART communication is command-based, classified into three types:

3.1 Universal Commands

Standardized commands understood by all HART devices. Examples include:

Reading primary variables

Getting device identification

Checking device status

3.2 Common Practice Commands

Used by many devices to support commonly implemented features:

Calibration

Range setting

Loop testing

3.3 Device-Specific Commands

Proprietary commands implemented by device manufacturers to enable advanced functionality unique to their instruments.

Most HART-enabled instruments support all three command levels for maximum functionality.

4. Key Features of HART Instruments

4.1 Enhanced Diagnostics and Remote Maintenance

HART instruments provide access to 30–40 parameters including status flags, error codes, and historical data. Benefits include:

Remote access to device health information

Reduced need for manual inspections

Predictive maintenance by analyzing trends and early warnings

Example: Maintenance teams can create digital records including manufacturer data, installation date, calibration history, and material specifications. Remote diagnostics minimize site visits and improve efficiency.

4.2 Multi-variable Capability

Many HART devices can transmit up to four process variables simultaneously. This:

Reduces the number of instruments required

Minimizes mounting space on process equipment

Cuts installation costs

4.3 Flexible Communication Modes

Point-to-Point: One device per loop; 4–20 mA carries analog and FSK carries digital data

Multi-drop Mode: Multiple devices (up to 15 for Revision 5, up to 63 for Revision 7) share a single loop, analog signal fixed at 4 mA

4.4 Digital Functionality and Smart Configuration

HART enables digital features such as:

Remote device configuration

Parameter tuning

Online zero/span calibration

On-the-fly diagnostics

4.5 Intrinsically Safe and Bus-powered

HART-compliant devices meet intrinsic safety standards, making them suitable for explosive environments like oil & gas and chemical industries. Power can be supplied through the signal loop, simplifying field wiring.

4.6 High Interoperability

Thanks to standardized Device Description Language (DDL), HART devices from different manufacturers can work together seamlessly as long as they conform to the HART protocol specifications. This simplifies system integration and allows flexibility in device selection.

5. Advantages Summary

| Feature | Description |

|---|---|

| Compatibility | Uses existing 4–20 mA wiring without rewiring |

| Rich Diagnostics | Real-time device health, fault alerts, calibration history |

| Reduced Maintenance Cost | Remote access minimizes manual inspections and unplanned downtime |

| Smart Configuration | Remote calibration, tuning, and setting adjustments |

| Multi-variable Capability | Multiple values via one device |

| Communication Flexibility | Point-to-point and multi-drop configurations supported |

| Intrinsic Safety | Certified for hazardous locations |

| Vendor Interoperability | Supports multi-brand integration through DDL |

6. Conclusion

HART protocol provides a cost-effective and future-proof pathway to digitizing industrial automation. It balances the reliability of analog control with the flexibility of digital data access, paving the way for intelligent maintenance, efficient configuration, and long-term asset optimization. As industrial digitalization continues, HART remains a cornerstone protocol for smart instrumentation.