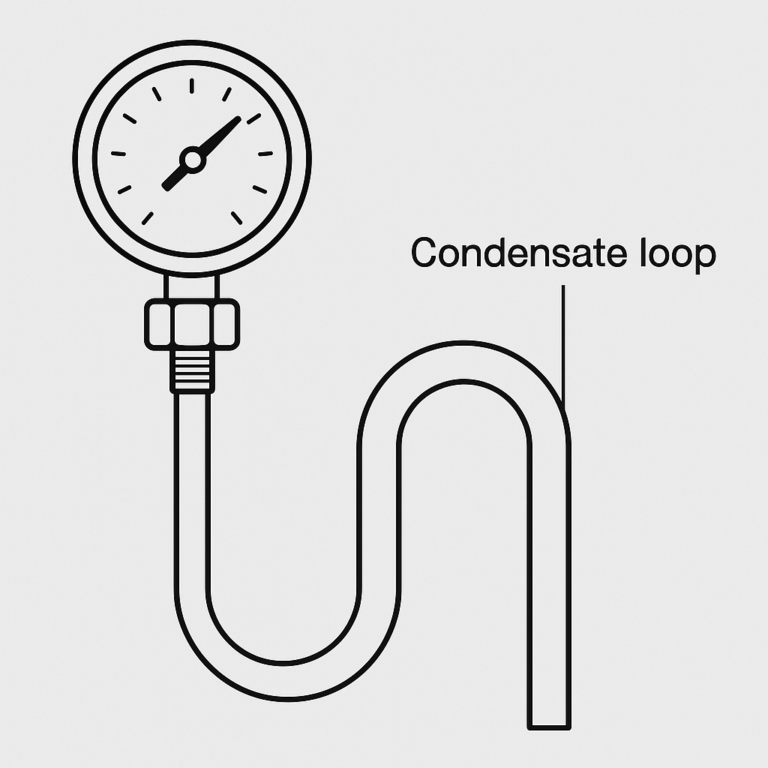

In high-temperature steam or thermal fluid systems, pressure measurement presents unique challenges. One essential accessory that ensures safe and accurate operation is the condensate loop, also known as a siphon tube, cooling loop, or pigtail. This simple yet crucial U-shaped or coiled pipe is installed between the pressure gauge and the process connection point. Here’s why it matters:

1. Temperature Isolation to Protect the Gauge

When measuring high-temperature steam or hot media, the siphon tube holds a small amount of condensate water inside. This water forms a liquid seal that prevents direct contact between the hot medium and the pressure gauge’s sensitive internal components (like the Bourdon tube). This protection prevents overheating, which can damage the gauge or lead to inaccurate readings.

2. Buffering Pressure Surges and Pulsations

The curved structure of the siphon tube acts like a mechanical buffer. It helps absorb pressure spikes, water hammer effects, and pulsating flows, reducing the mechanical impact on the pressure gauge. This not only stabilizes the readings but also extends the life of the instrument.

3. Reducing Corrosion and Scaling Risks

In systems that contain corrosive or scaling-prone media, the condensate inside the siphon tube provides a protective barrier. This liquid barrier prevents harmful substances from entering the pressure gauge, minimizing corrosion, blockages, and other long-term maintenance issues.

4. Improved Measurement Stability

Water, as a liquid transmission medium, offers more stable pressure transfer compared to gases. The presence of condensate inside the siphon tube helps maintain consistent pressure transmission, reducing the influence of temperature fluctuations on the gauge reading.

5. Installation and Maintenance Guidelines

Applications: Commonly used in steam boilers, thermal pipelines, and high-temperature pressure systems.

Design Options: Available in U-shaped, circular, or spiral forms to allow sufficient cooling and condensate formation.

Installation Tips:

Install vertically or at an inclined angle to allow proper condensate retention.

Ensure periodic inspection and cleaning to avoid blockage and maintain correct condensate levels.

✅ Conclusion

The condensate loop is a small yet vital component that isolates heat, buffers pressure, and protects instrumentation. In any high-temperature or steam-based system, proper use of a siphon tube can significantly improve the reliability, accuracy, and lifespan of pressure gauges.

Whether you’re a plant engineer or an instrumentation technician, understanding and correctly applying siphon tubes is key to maintaining safe and efficient measurement systems.