Introduction

Ensuring a leak-free connection for gases or liquids is critical in industrial applications. To achieve this, a clear understanding of tapered pipe threads is essential. This article explores tapered pipe threads, their standards, differences, and the importance of proper sealing techniques.

Tapered vs. Parallel Threads

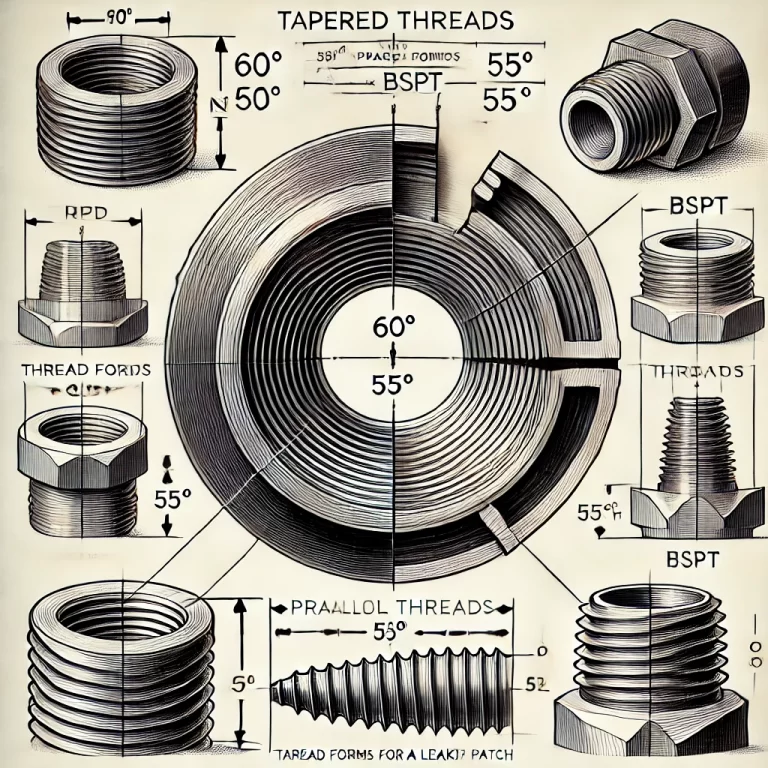

Pipe threads are categorized into two main types: tapered and parallel.

Tapered Threads are designed with a slight taper, allowing the male and female threads to wedge together tightly. This wedging action helps create a mechanically secure and leak-resistant connection.

Parallel Threads, in contrast, have a consistent diameter along their entire length and typically rely on gaskets, washers, or O-rings to create a seal.

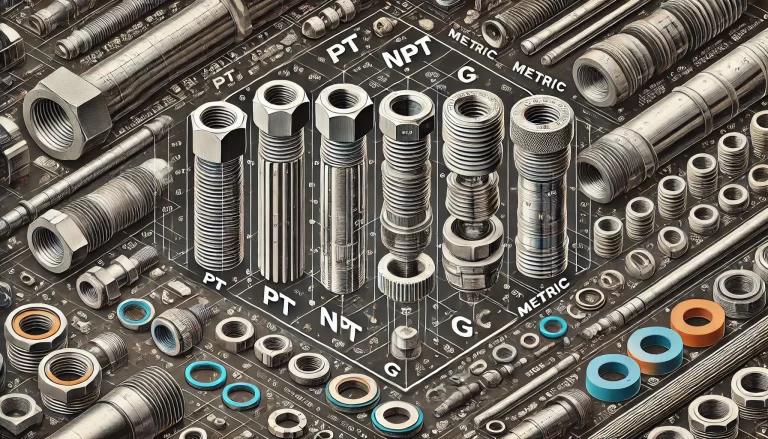

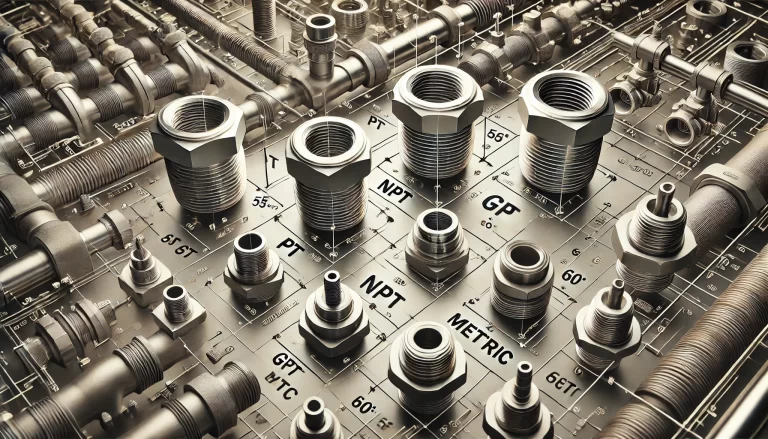

Common Standards of Tapered Threads

Two widely used international standards for tapered threads are:

NPT (National Pipe Thread Taper): Widely adopted in the United States and Canada.

BSPT (British Standard Pipe Taper): Predominantly used in Europe, Asia, and other regions influenced by British standards.

Why Are NPT and BSPT Threads Not Compatible?

Although similar in appearance, NPT and BSPT threads are not interchangeable due to several key differences:

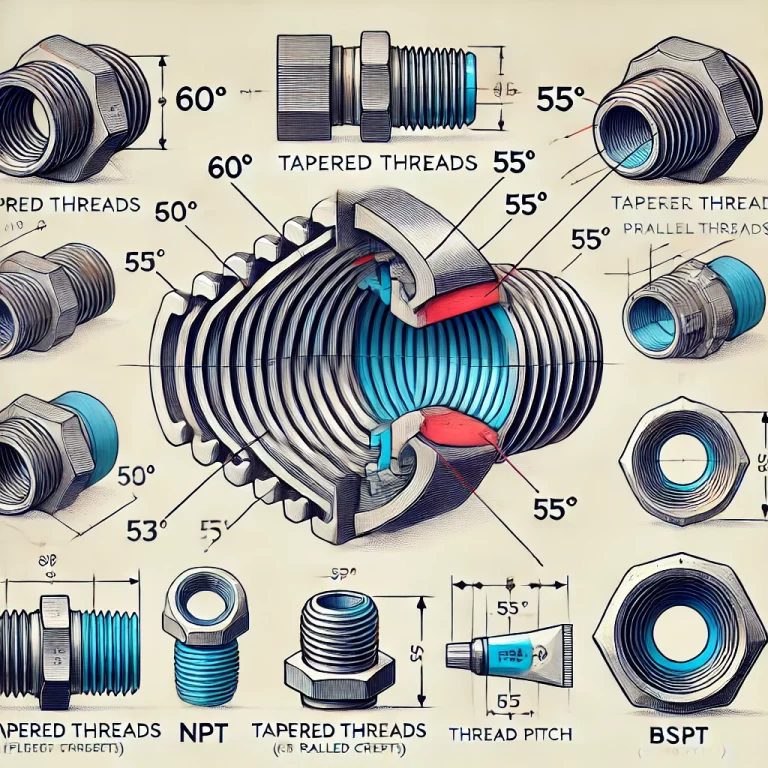

Thread Angle:

NPT threads have a 60° included angle.

BSPT threads have a 55° included angle.

Thread Form:

NPT threads have flattened crests and roots, resulting in a trapezoidal thread form.

BSPT threads have rounded crests and roots.

Thread Pitch (Threads per Inch – TPI):

Each thread standard specifies unique thread pitch values corresponding to specific pipe sizes. Even subtle differences in TPI can significantly impact compatibility.

Pipe vs. Tube

Understanding the difference between a pipe and a tube is also crucial when working with threaded connections:

Pipe: Usually characterized by thicker walls, greater rigidity, and standardized dimensions suitable for threading. Pipes commonly have sufficient wall thickness to accommodate cutting or molding threads.

Tube: Typically has thinner walls, is more flexible, and rarely threaded due to insufficient wall thickness.

Importance of Using Sealants

While tapered threads inherently provide strong mechanical connections, complete fluid-tight or gas-tight sealing often requires additional sealants. Sealants fill microscopic gaps between threads, preventing spiral leakage paths along the threaded connection. Additionally, sealants act as lubricants, easing the threading process and preventing thread galling or damage.

Caution: Care must be exercised when using sealants, especially with threads made from different materials. Over-tightening due to excessive sealant use may damage the connection or cause leakage.

American Thread Abbreviations:

Some commonly encountered abbreviations related to tapered pipe threads include:

NPT: National Pipe Thread Taper

FPT, FNPT, NPT(F): Female or internal tapered pipe thread

MPT, MNPT, NPT(M): Male or external tapered pipe thread

NPTF: National Pipe Taper Fuel, a “dry seal” thread designed for leak-free sealing without sealants.

Conclusion

Selecting the correct tapered pipe threads and properly matching thread standards (NPT or BSPT) are vital for leak-free performance and long-lasting reliability. Understanding these distinctions and the proper use of sealing materials ensures better mechanical strength and tighter seals.