Steam, as a critical energy carrier, finds extensive application in industrial heating, power generation, and production processes. This article provides a comprehensive overview of steam types, quality, measurement methods, common challenges, and associated instruments.

1. Types of Steam

Steam can be classified into several types based on its pressure, temperature, and state:

Saturated Steam

- Produced when water boils at a specific pressure, reaching a state where temperature and pressure are directly correlated (saturation state).

- Commonly used for heating and sterilization due to high energy efficiency.

Superheated Steam

- Formed by further heating saturated steam, increasing its temperature above the saturation point for the corresponding pressure.

- High enthalpy makes it ideal for power equipment (e.g., turbines) or long-distance transport.

Wet Steam

- Contains water droplets within the vapor phase, typically described using “steam quality,” which represents the mass fraction of vapor in the mixture.

- Has lower heat transfer efficiency and can cause corrosion to equipment.

Condensate

- Steam that has cooled or undergone pressure reduction, returning to liquid form.

- Often recycled to enhance energy efficiency.

2. Steam Quality and Its Importance

The quality of steam directly impacts heat transfer efficiency and equipment safety.

Steam Quality (X)

- Defined as the mass fraction of vapor in wet steam, with values ranging from 0 to 1. For instance, a steam quality of 0.9 indicates 90% vapor and 10% liquid water.

Factors Affecting Steam Quality

- Performance of steam generators.

- Insulation conditions of piping.

- Pressure fluctuations in the system.

Enthalpy of Steam

- Saturated and superheated steam possess distinct specific enthalpy values, which can be referenced in thermodynamic tables for precise calculations.

3. Steam Measurement Methods

Accurate measurement of steam involves monitoring its flow rate, pressure, temperature, and quality.

3.1. Flow Rate Measurement

Several methods are used for measuring steam flow:

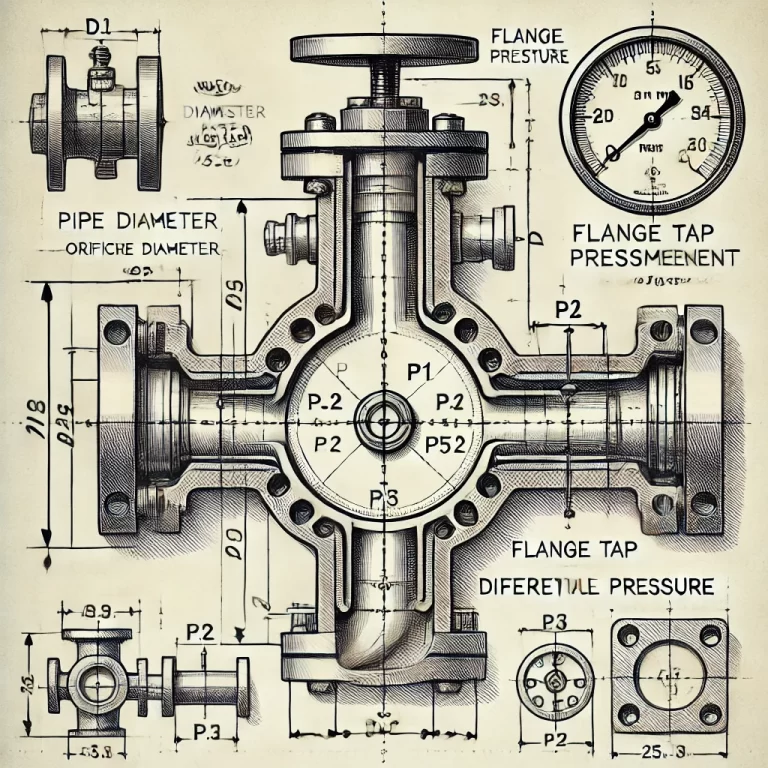

Differential Pressure Flow Meters

- Employ devices such as orifice plates, Venturi tubes, or nozzles to calculate flow based on pressure differences.

- Advantages: Well-suited for high-temperature and high-pressure steam, proven technology.

- Disadvantages: Significant pressure loss and sensitivity to operating conditions.

Vortex Flow Meters

- Utilize the Kármán vortex street principle, measuring vortex frequency to determine flow.

- Advantages: No moving parts, suitable for a wide flow range.

- Disadvantages: Sensitive to low flow rates and pipeline vibrations.

Thermal Mass Flow Meters

- Measure heat exchange between steam and the sensor to calculate mass flow.

- Advantages: Direct mass flow measurement, effective for low-velocity steam.

- Disadvantages: Affected by steam quality variations.

Ultrasonic Flow Meters

- Rely on time-of-flight or Doppler effect principles for flow measurement.

- Advantages: No pressure loss, suitable for large pipelines.

- Disadvantages: Require high-quality steam for accurate readings.

3.2. Pressure Measurement

- Commonly uses capacitance, piezoresistive, or silicon-based pressure transducers designed to withstand high temperatures and pressures.

3.3. Temperature Measurement

- Thermocouples: K-type or S-type thermocouples are commonly used for high-temperature steam.

- Resistance Temperature Detectors (RTDs): Offer high accuracy but are limited to lower temperature ranges compared to thermocouples.

3.4. Steam Quality Measurement

- Humidity Meters: Measure the water content in wet steam.

- Thermal Measurement Instruments: Calculate steam quality indirectly using steam enthalpy and pressure data.

4. Common Challenges in Steam Measurement

Impact of Wet Steam

- Water droplets in wet steam can distort readings.

- Solution: Use separators or dryers before measurement.

Fluctuations in Pressure and Temperature

- Variations affect flow calculation accuracy.

- Solution: Use instruments with fast dynamic response and install stabilizers.

Inappropriate Instrument Selection

- Instruments not suited to specific operating conditions can lead to errors.

- Solution: Choose instruments based on steam characteristics, velocity, and temperature ranges.

Steam Leakage

- Leaks in pipelines reduce actual flow.

- Solution: Conduct regular inspections of pipelines and instrument connections.

5. Common Steam Measurement Instruments

| Instrument Type | Measured Parameter | Key Features |

|---|---|---|

| Differential Pressure | Flow Rate | Robust for high-temp applications |

| Vortex Flow Meters | Flow Rate | Low maintenance, broad range |

| Ultrasonic Flow Meters | Flow Rate | No pressure drop, non-invasive |

| Pressure Transmitters | Pressure | High sensitivity and durability |

| Thermocouples / RTDs | Temperature | Accurate and reliable |

6. Additional Knowledge About Steam

Steam Transmission and Energy Efficiency

- Proper insulation of steam pipelines reduces heat loss.

- Recycling condensate enhances overall energy utilization.

Steam Safety

- High-temperature and high-pressure steam systems require strict prevention of leaks and explosions.

- Equipment must comply with standards like ASME for pressure vessels.

Steam and Environmental Considerations

- While steam is an eco-friendly energy carrier, its generation is energy-intensive.

- Improving boiler efficiency and minimizing transport losses are essential for reducing carbon emissions.

Conclusion

A proper understanding of steam and its measurement is critical for optimizing energy use, ensuring equipment safety, and protecting the environment. By addressing challenges in steam measurement and selecting appropriate instruments, industries can achieve significant improvements in efficiency and sustainability.