In the world of safety and automation, understanding the distinctions between SIL (Safety Integrity Level), SIS (Safety Instrumented System), and SIF (Safety Instrumented Function) is crucial. These concepts form the backbone of ensuring industrial safety, particularly in environments like chemical plants, oil refineries, and other high-risk industries. Below is a comprehensive guide to clarify the differences and relationships among these terms.

1. Safety Integrity Level (SIL)

SIL is a measure of the level of risk reduction provided by a safety function, or the reliability of a safety system. It is used to quantify the performance required for a Safety Instrumented Function (SIF) to maintain acceptable levels of risk.

Key Characteristics of SIL:

Risk Reduction Factor (RRF): SIL indicates the required reduction in risk. The higher the SIL, the lower the allowable probability of failure on demand. It is categorized into four levels:

- SIL 1: Lowest level of safety integrity, moderate risk reduction (RRF of 10 to 100).

- SIL 2: Higher risk reduction (RRF of 100 to 1,000).

- SIL 3: Even higher reduction (RRF of 1,000 to 10,000).

- SIL 4: The highest level of risk reduction (RRF of 10,000 to 100,000), rarely used in industrial applications due to the extreme levels of reliability needed.

Performance Metrics: SIL is determined based on:

- Probability of Failure on Demand (PFD): Likelihood that a system will fail to perform its required function when needed.

- Average Frequency of Dangerous Failures: It includes both systematic and random failures that could occur within the system.

Industry Standards: SIL levels are defined in standards like IEC 61508 and IEC 61511, which provide guidance on functional safety in industries like process control and automation.

How is SIL Determined?

SIL determination typically involves a risk assessment process, such as:

- Layer of Protection Analysis (LOPA): Evaluates various risk reduction measures and determines the necessary SIL.

- Fault Tree Analysis (FTA) or Hazard and Operability Study (HAZOP): Helps in identifying potential failures and assigning SIL levels to mitigate risks.

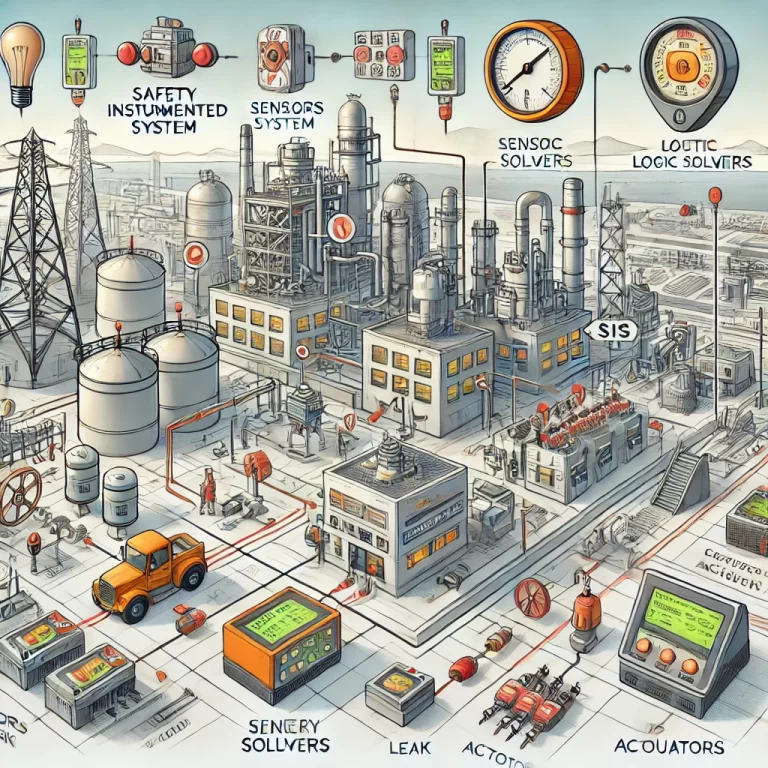

2. Safety Instrumented System (SIS)

SIS refers to the overall system designed to monitor and control hazardous processes. Its purpose is to automatically take actions (e.g., shutting down a process, isolating a section of equipment) in response to dangerous conditions, preventing accidents, injuries, or significant financial loss.

Key Characteristics of SIS:

Components: An SIS typically consists of sensors, logic solvers (like PLCs), and actuators.

- Sensors: Detect hazardous conditions or failures (e.g., pressure, temperature).

- Logic Solvers: Perform the decision-making process. It processes input from sensors and determines whether a corrective action (like shutting off valves) should be taken.

- Actuators: Carry out the required actions, like closing a valve or shutting down equipment.

Relation to SIL: The performance of an SIS is quantified by its SIL. The higher the required SIL level for the system, the more reliable and robust the SIS must be.

Lifecycle Approach: The design, implementation, maintenance, and validation of an SIS follow a safety lifecycle, as defined by standards like IEC 61508/61511. This ensures the SIS remains effective throughout its operational life.

SIS Objectives:

- Prevention of Incidents: Automatically activate protective measures when a hazardous event occurs.

- Mitigation of Risk: By implementing safety measures, the SIS helps reduce the potential consequences of hazardous events, ensuring the safety of personnel, the environment, and equipment.

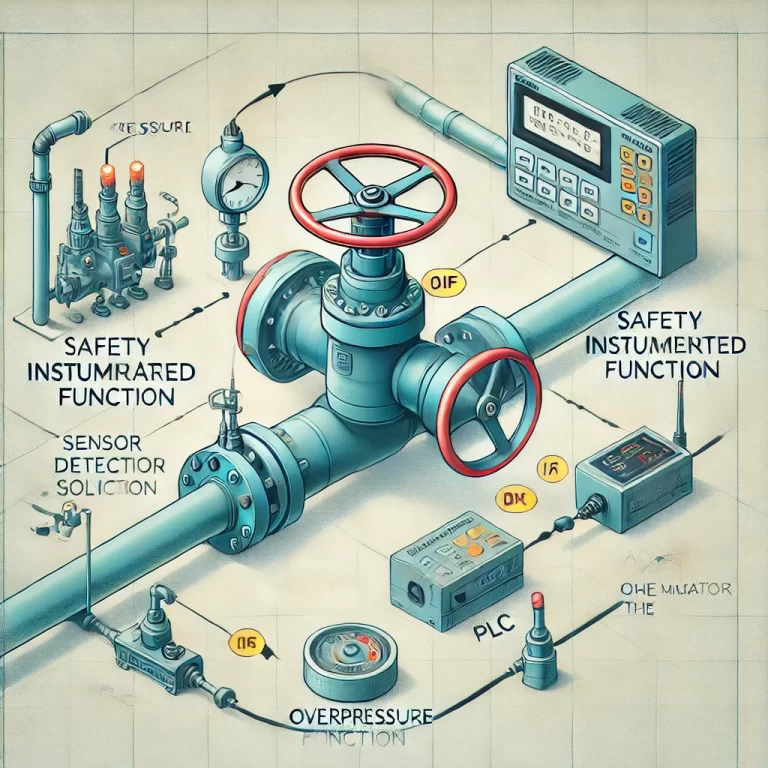

3. Safety Instrumented Function (SIF)

A SIF is a specific function carried out by the SIS to reduce risks associated with hazardous events. It refers to the individual safety actions within an SIS, designed to achieve a specific risk reduction target.

Key Characteristics of SIF:

Definition: A SIF is a discrete function or operation within an SIS that is designed to prevent a specific hazardous event by taking predetermined actions (e.g., stopping a process or releasing pressure).

Risk Reduction Role: Each SIF is assigned a specific SIL level, depending on the risk associated with the event it is designed to prevent. For example, a SIF responsible for emergency shutdown might have a SIL 3 rating, reflecting the need for a high degree of reliability in preventing an accident.

Examples of SIFs:

- A valve that closes to isolate a process during overpressure conditions.

- A temperature sensor that shuts down a heater if it exceeds safe operating limits.

- A gas detector that triggers ventilation systems when a flammable gas is detected.

SIF and SIL Relationship:

Every SIF within an SIS must achieve the risk reduction required by its assigned SIL. The reliability and design of a SIF, including its redundancy, fault tolerance, and failure detection mechanisms, are determined by the necessary SIL.

4. Comparison and Relationship Between SIL, SIS, and SIF

To clarify how these concepts interrelate:

- SIL (Safety Integrity Level) is the measure of performance and reliability that a SIF (Safety Instrumented Function) must meet to achieve the necessary risk reduction.

- SIS (Safety Instrumented System) is the overarching system that contains one or more SIFs, responsible for carrying out protective actions in the event of a dangerous condition.

- SIF (Safety Instrumented Function) is the individual safety function or action within the SIS that addresses specific hazardous conditions.

Analogy Example:

Think of a car’s safety system:

- SIS is like the entire braking system, responsible for ensuring the car can stop when necessary.

- SIF is like the anti-lock braking function (ABS) that prevents wheel lock-up during sudden braking.

- SIL is the required reliability of the ABS to prevent accidents – for instance, how often the ABS should perform correctly under emergency conditions.

5. Designing and Implementing SIL, SIS, and SIF

When designing a safety system, the steps typically follow this order:

- Identify Hazards: Conduct a hazard analysis (e.g., HAZOP or FMEA) to determine the potential risks.

- Assign SIFs: For each identified hazard, define the necessary SIF to mitigate it.

- Determine SIL: Perform risk assessments (e.g., LOPA) to determine the required SIL for each SIF.

- Design the SIS: Design and implement the SIS, ensuring that it meets the required SIL levels for each SIF.

- Testing and Maintenance: Perform regular tests, validation, and maintenance to ensure that the SIS and its associated SIFs maintain their required SIL levels throughout their operational life.

6. Conclusion

In summary:

- SIL is a measure of the reliability of a safety function, defining how effectively a system reduces risk.

- SIS is the complete system designed to monitor and control risks.

- SIF refers to individual functions within the SIS, designed to perform specific risk-reducing actions.

Understanding and implementing these concepts correctly is critical for ensuring functional safety in hazardous environments. Properly designed SIS with appropriate SIFs, all operating under the necessary SIL levels, help protect lives, the environment, and equipment from catastrophic failures.