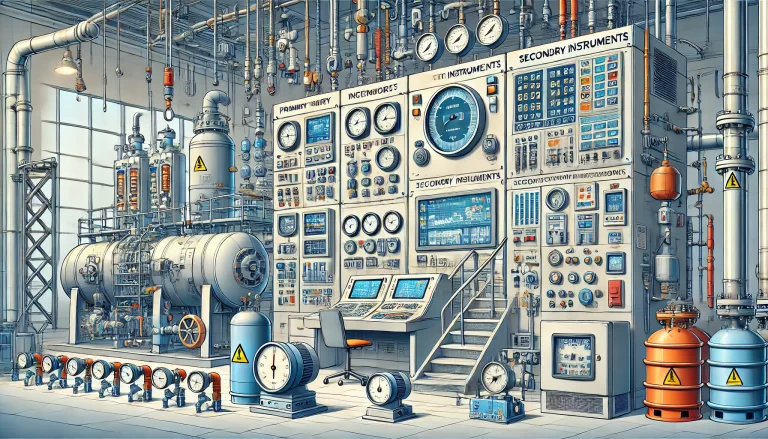

In the realm of industrial automation and control systems, secondary instruments, or secondary devices, play a crucial role in the accurate and reliable handling of data. Unlike primary instruments, which directly measure physical quantities such as temperature, pressure, or flow, secondary instruments process, display, or interpret these measurements, making them more accessible and actionable for operators or automated systems. This article delves into what secondary instruments are, how they function, and where they are commonly applied.

Primary vs. Secondary Instruments

The distinction between primary and secondary instruments lies primarily in their roles in measurement and control:

- Primary Instruments: These are devices that come into direct contact with the parameter being measured. Examples include sensors and transducers that can detect changes in physical conditions like temperature, pressure, or level.

- Secondary Instruments: These devices receive signals from primary instruments and translate, display, or control these readings. In doing so, secondary instruments ensure that the raw data from primary instruments can be interpreted, recorded, or used to trigger specific responses within a control system.

In essence, while primary instruments are responsible for capturing data, secondary instruments make that data usable and interpretable.

Key Functions of Secondary Instruments

Secondary instruments fulfill various roles that contribute to smooth, automated processes in industrial settings. The following are their primary functions:

Signal Conversion:

- Signals output by primary instruments may not be suitable for direct display or control purposes. Secondary instruments can convert these signals (often in analog or digital form) into standardized formats. For example, a temperature sensor might produce a millivolt output signal, which a secondary instrument could convert into a digital display or an industry-standard 4-20 mA current loop signal.

- This conversion allows the signal to be compatible with other system components, improving consistency and interoperability.

Signal Amplification:

- The signals from primary instruments are sometimes weak and prone to noise interference during transmission. Secondary instruments often amplify these signals, maintaining the integrity of the data as it moves through various control and monitoring devices.

- Amplification is crucial, especially in large systems where signals need to travel over long distances without degradation.

Data Recording and Display:

- Secondary instruments often display measurement values in user-friendly formats on dials, digital screens, or computer interfaces. This display allows operators to monitor real-time data effectively.

- In addition, secondary instruments can store this data for later analysis, which is particularly valuable in applications where trends or historical data need to be reviewed for quality control or predictive maintenance.

Control and Alarm Functions:

- Secondary instruments are typically configured to trigger alarms or control functions based on pre-set parameters. If a measurement exceeds a safe range, the secondary instrument can initiate an alert or even take corrective actions, like adjusting a valve or turning off machinery.

- This feature is vital in safety-critical applications, where immediate response is required to avoid damage or hazards.

Common Types of Secondary Instruments

Secondary instruments come in various forms, each designed to support specific types of primary measurements. Here are a few prominent examples:

Digital and Analog Indicators:

- Digital indicators present measurements in numerical form, allowing for precise readings. Analog indicators, like gauges with needles, offer a quick visual representation, often used for pressure or temperature readings.

Signal Conditioners and Converters:

- Signal conditioners modify signals to make them suitable for further processing or display. For instance, a signal conditioner might adjust a voltage signal to meet the input requirements of a secondary device.

- Signal converters transform one type of signal into another, such as converting a voltage output into a current loop, which is common for transmitting signals over longer distances.

Controllers:

- Secondary controllers, like proportional-integral-derivative (PID) controllers, maintain setpoints for various parameters within a system. They monitor feedback from primary instruments and adjust system outputs to keep measurements within a desired range.

Recorders and Data Loggers:

- These instruments store time-series data, offering insights into trends or anomalies in a process. They are used extensively in industries like pharmaceuticals, where maintaining specific conditions is crucial for compliance and quality.

Alarms and Safety Relays:

- Alarms generate audio-visual notifications when a parameter exceeds safe operating limits. Safety relays can also trigger emergency shutdowns in response to certain conditions.

Applications of Secondary Instruments

Secondary instruments are indispensable in various industries, from manufacturing to utilities. Here are a few notable applications:

Manufacturing:

- In production lines, secondary instruments monitor temperature, pressure, and flow in processes like injection molding, chemical reactions, and packaging. The data they provide is crucial for quality assurance, ensuring that each batch meets required specifications.

Oil and Gas:

- In the oil and gas industry, secondary instruments are essential for maintaining pressure levels, temperature, and flow rates in pipelines. They provide real-time feedback, preventing leaks, explosions, or other hazardous situations.

Water Treatment:

- Secondary instruments in water treatment plants measure pH, turbidity, and chemical concentrations. This data guides adjustments to maintain safe and compliant water quality.

Energy and Power Generation:

- Power plants rely on secondary instruments to regulate temperature, pressure, and coolant flow. This ensures efficient operation and prevents overheating, which is crucial for safety and reliability.

Pharmaceuticals and Food Processing:

- In these industries, maintaining precise conditions is critical for product quality and compliance. Secondary instruments ensure that environmental factors like temperature and humidity stay within required ranges.

Conclusion

Secondary instruments are the backbone of automated control and monitoring systems. By transforming raw measurements into standardized signals, amplifying weak signals, displaying readable data, and providing control responses, these instruments facilitate safe and efficient operations across many industries. As technology advances, secondary instruments continue to evolve, integrating features such as digital connectivity and data analytics, making them even more integral to modern industrial processes. Whether in manufacturing or environmental monitoring, secondary instruments are essential for turning raw data into actionable insights, safeguarding systems, and maintaining quality control.