A Safety Programmable Logic Controller (Safety PLC) is a specialized type of PLC designed to ensure industrial processes operate safely, particularly in environments where human safety, equipment reliability, and environmental protection are critical. Unlike standard PLCs, Safety PLCs adhere to rigorous safety standards and are equipped with unique features that prevent hazards and minimize risks.

Key Features of Safety PLCs

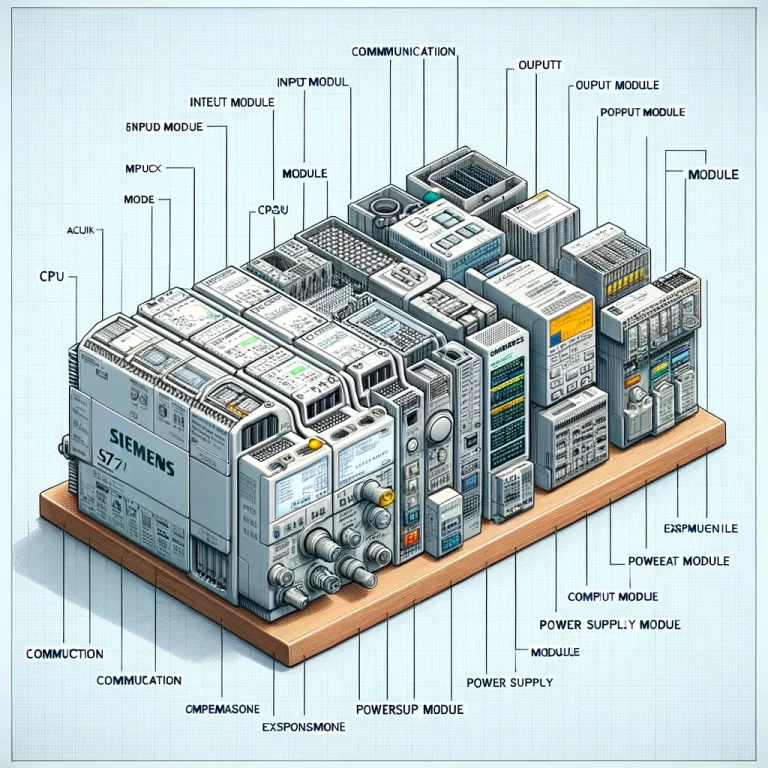

Redundant Design

- Safety PLCs often incorporate a dual-channel or multi-channel redundancy system, ensuring that even if one component fails, the system can continue to operate safely.

- The redundancy extends across processors, communication paths, and input/output (I/O) modules.

Compliance with Safety Standards

- Safety PLCs are developed to comply with international functional safety standards, such as:

- IEC 61508: Functional safety of electrical/electronic/programmable systems.

- ISO 13849: Safety of machinery.

- These standards help define Safety Integrity Levels (SIL) or Performance Levels (PL) that the PLC can achieve, ensuring it meets specific risk reduction requirements.

- Safety PLCs are developed to comply with international functional safety standards, such as:

Self-Diagnostic Capabilities

- A Safety PLC continuously monitors its hardware and software for faults.

- If an anomaly is detected, the PLC ensures the system transitions to a predefined safe state (e.g., shutting down equipment or stopping a process).

Specialized Safety Functions

- Safety PLCs include pre-designed safety instruction sets to handle critical operations like:

- Emergency stops (E-Stops)

- Safety gate monitoring

- Two-hand control systems

- Light curtains or pressure mat monitoring

- These instructions simplify programming while ensuring compliance with safety standards.

- Safety PLCs include pre-designed safety instruction sets to handle critical operations like:

Secure Operation

- Safety PLCs are designed to prevent unauthorized access or tampering with safety logic. This is achieved through:

- Password protection

- Encrypted communications

- Role-based access control

- Safety PLCs are designed to prevent unauthorized access or tampering with safety logic. This is achieved through:

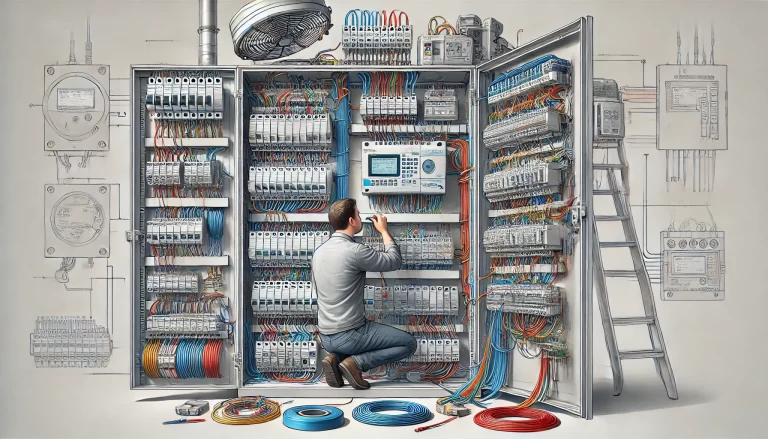

Integration with Standard PLCs

- In many systems, Safety PLCs operate alongside standard PLCs. The Safety PLC handles safety-critical tasks, while the standard PLC manages non-critical automation processes. Integration ensures seamless communication and control.

Applications of Safety PLCs

Safety PLCs are indispensable in industries where risks to human life, equipment, or the environment are high. Common applications include:

Industrial Automation

- Used in factories for machines with moving parts, such as conveyors, robotic arms, and presses. Safety PLCs ensure operators are protected from potential injuries.

Process Industries

- In chemical, oil, and gas facilities, Safety PLCs monitor pressure, temperature, and hazardous material levels to prevent catastrophic failures.

Energy Sector

- Safety PLCs are vital in power plants, wind turbines, and substations to handle emergency shutdowns and protect against electrical faults.

Material Handling Systems

- Automated warehouses, cranes, and elevators rely on Safety PLCs to ensure the safe movement of goods and personnel.

Transportation

- In railways, Safety PLCs manage signaling systems and automatic train protection (ATP) to avoid collisions and derailments.

Differences Between Standard PLCs and Safety PLCs

| Aspect | Standard PLC | Safety PLC |

|---|---|---|

| Primary Function | General automation control | Safety-critical control |

| Redundancy | Not typically present | Essential for fault tolerance |

| Safety Standards | Not required | Must comply with safety certifications |

| Failure Response | May continue operating despite faults | Ensures the system transitions to a safe state |

| Use Case | Routine process automation | High-risk, safety-critical applications |

Why Safety PLCs are Critical

Personnel Protection

- In industrial environments, moving machinery, high voltage, or hazardous substances pose significant risks. Safety PLCs actively mitigate these risks, preventing injury or loss of life.

Regulatory Compliance

- Many industries are required by law to use safety-certified systems. Failure to comply can lead to legal penalties or operational shutdowns.

Cost Efficiency

- While Safety PLCs may have higher upfront costs, their ability to prevent accidents and downtime results in long-term savings.

Operational Reliability

- By maintaining safe operations even in the event of hardware or software failure, Safety PLCs ensure consistent productivity and process integrity.

Challenges in Implementing Safety PLCs

Initial Costs

- Safety PLCs and their associated components are typically more expensive than standard PLCs due to the need for advanced technology and certification processes.

Complexity

- Setting up a Safety PLC requires a deep understanding of safety standards, system design, and programming.

Maintenance

- Regular testing and validation of Safety PLCs are essential to ensure ongoing compliance and functionality.

The Future of Safety PLCs

As industries continue to adopt advanced automation technologies, the role of Safety PLCs will expand. Future developments include:

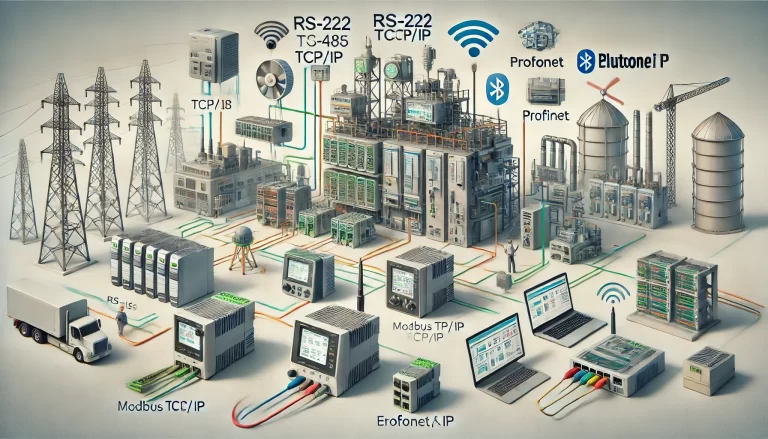

Integration with IoT and AI

- Safety PLCs will increasingly leverage data analytics and artificial intelligence to predict and prevent potential hazards.

Improved Cybersecurity

- As industrial systems become more connected, cybersecurity will remain a top priority for protecting safety-critical processes.

Miniaturization and Cost Reduction

- Advancements in technology will make Safety PLCs more compact and affordable, broadening their accessibility across industries.

Conclusion

Safety PLCs are essential for ensuring that industrial processes run safely and efficiently in high-risk environments. Their robust design, compliance with international safety standards, and ability to handle critical safety functions make them indispensable for modern industries. Despite the challenges in implementation, their benefits—ranging from saving lives to minimizing operational risks—far outweigh the costs. As industries evolve, Safety PLCs will continue to play a pivotal role in shaping safer and more reliable industrial systems.