PROFIBUS (Process Field Bus) is a widely-used standard for fieldbus communication in industrial automation systems. Developed in 1987 by a group of companies led by Siemens and supported by several research institutes, PROFIBUS is a crucial technology in industrial control systems. It is important to note that PROFIBUS and PROFINET (used in industrial Ethernet) are two distinct communication protocols. This article delves into the two most commonly used variations of PROFIBUS—PROFIBUS DP and PROFIBUS PA—exploring their features, applications, and differences.

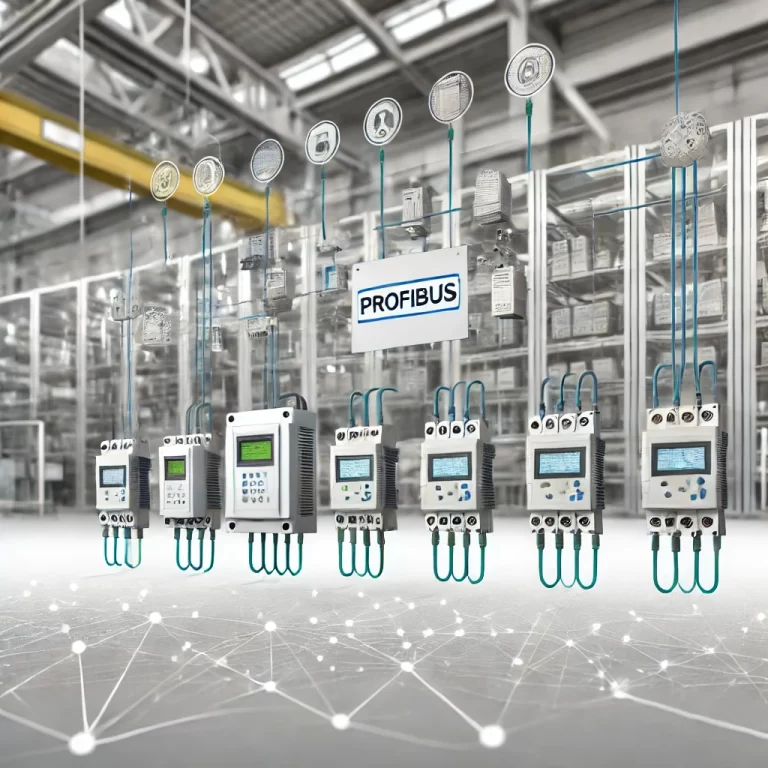

1. PROFIBUS DP: Distributed Peripherals for Factory Automation

PROFIBUS DP (Decentralized Peripherals) is primarily used in factory automation applications. It facilitates communication between a central controller (like a PLC) and a wide range of peripheral devices such as sensors, actuators, and I/O modules. It enables high-speed data transmission, real-time control, and diagnostic functions, which are essential for efficient and reliable factory automation.

Key Features of PROFIBUS DP:

- High-Speed Data Transmission: PROFIBUS DP supports high-speed data transfer, ensuring fast communication between devices.

- Real-Time Control: With PROFIBUS DP, real-time control is possible, which is crucial in automation systems where timing and synchronization are critical.

- Flexible Connectivity: The protocol allows multiple devices to be connected through a central control unit, including PLCs, sensors, actuators, and drives.

- RS-485 Physical Layer: The physical layer of PROFIBUS DP uses RS-485, a robust communication standard that supports reliable data transmission over long distances.

- Maximum Transmission Distance: PROFIBUS DP can cover up to 1200 meters, which allows for widespread distribution of devices within the factory.

- Multi-Master Capability: PROFIBUS DP supports a multi-master architecture, meaning multiple controllers can communicate with the network simultaneously, increasing system flexibility.

PROFIBUS DP is commonly used in manufacturing plants, automotive production lines, and other environments where fast, reliable, and decentralized control of machines and devices is required.

2. PROFIBUS PA: Process Automation for Hazardous Environments

PROFIBUS PA (Process Automation) is designed specifically for process automation systems, especially in industries where safety is a priority, such as chemical, oil, gas, and pharmaceuticals. It is inherently safe and suitable for use in explosive environments, as it adheres to stringent safety standards. PROFIBUS PA allows for communication between control systems and process measurement devices, including temperature sensors, flow meters, and control valves.

Key Features of PROFIBUS PA:

- Intrinsic Safety: PROFIBUS PA is an intrinsically safe protocol, which means it is designed to prevent sparks or heat generation that could cause explosions in hazardous environments (Ex-Zone 0 and Ex-Zone 1).

- Power Over the Bus: One unique feature of PROFIBUS PA is its ability to provide power to connected devices over the communication bus itself. This simplifies wiring and reduces installation costs in process automation systems.

- Low Data Transmission Speed: PROFIBUS PA operates at a lower data transmission rate of 31.25 kbit/s, which is sufficient for the slower-paced process control tasks where high-speed data transfer is not critical.

- Long-Distance Communication: Despite its lower data rate, PROFIBUS PA supports long-distance communication with a maximum range of up to 1900 meters, making it ideal for large-scale industrial applications.

- Specialized Physical Layer (MBP): The physical layer of PROFIBUS PA uses the MBP (Manchester Bus Powered) standard, which allows multiple devices to be connected to the same communication line, while still maintaining power and communication integrity over long distances.

PROFIBUS PA is typically used in industries such as chemical manufacturing, oil and gas, and any process-driven industry that requires communication with field devices in hazardous or explosive environments.

3. Key Differences Between PROFIBUS DP and PROFIBUS PA

While both PROFIBUS DP and PROFIBUS PA are based on the same core protocol, there are some important distinctions that make each suitable for specific applications:

- Application Focus: PROFIBUS DP is suited for factory automation, controlling devices such as PLCs, drives, and I/O modules. PROFIBUS PA, on the other hand, is used in process automation, typically involving sensors and actuators for monitoring and controlling processes.

- Data Transmission Speed: PROFIBUS DP offers high-speed communication, making it ideal for real-time applications. PROFIBUS PA, however, operates at a slower data transmission rate, which is adequate for the slower-paced nature of process control.

- Power Supply: PROFIBUS DP relies on external power sources for connected devices, while PROFIBUS PA can supply power to devices over the communication line itself, reducing the complexity of wiring in process automation.

- Safety Features: PROFIBUS PA is specifically designed for hazardous environments and adheres to intrinsic safety standards, which is essential for industries such as oil and gas. PROFIBUS DP does not have these safety features and is generally used in non-hazardous environments.

- Physical Layer: PROFIBUS DP uses the RS-485 standard, while PROFIBUS PA uses the MBP standard for communication, which enables power transmission and supports longer cable lengths.

4. Simultaneous Use of PROFIBUS DP and PA

In some complex industrial applications, both PROFIBUS DP and PROFIBUS PA can be used together. For example, in a process automation system, PROFIBUS DP can serve as the backbone network, connecting high-speed control devices like PLCs and I/O modules, while PROFIBUS PA can be used to connect process measurement devices in hazardous areas. By using a converter or gateway, the two networks can be interconnected, enabling seamless communication between factory and process automation systems.

Conclusion

Both PROFIBUS DP and PROFIBUS PA are essential communication protocols in industrial automation, but they are designed for different applications. PROFIBUS DP is ideal for high-speed, real-time factory automation, while PROFIBUS PA is specialized for process automation in hazardous environments. Understanding the key differences and strengths of each protocol can help engineers select the right one for their specific automation needs.