In chemical manufacturing, stable operations are crucial—just like driving a car smoothly, where speed, direction, throttle, and brakes must work in harmony. If any of these components fluctuate too much, accidents are inevitable. Process fluctuations, including abnormal changes in temperature, pressure, flow rate, raw material composition, or equipment status, are among the most common and dangerous risk factors in chemical plants.

Many safety systems, such as automatic control systems, safety interlocks, and online monitoring, assume the process is operating in a “stable state.” However, when the process itself is unstable, these systems may fail—either by delayed alarms, incorrect actions, or even complete failure to respond.

Why Is “Process Instability” Dangerous?

Many chemical accidents are not caused by equipment aging or human error, but by sudden changes in process conditions, which operators or systems fail to react to in time.

For example, during the “11·28” explosion, abnormal pressure increases were not promptly detected, and a gas leak went unnoticed. The automatic control system failed, resulting in a catastrophic explosion.

Similarly, the “10·14” incident in an industrial park occurred because process parameters fluctuated beyond acceptable limits, and the interlock system failed to respond in time, bypassing safety barriers and leading to severe consequences.

These examples highlight that no matter how advanced the control system, it cannot save an unstable process. A stable process is the foundation for safety systems to work effectively.

What is a “Process Stability Management System”?

A “Process Stability Management System” is a comprehensive framework designed to maintain the safe, stable, and efficient operation of chemical processes. It is not a single piece of equipment or policy but a systemic approach that spans the entire production process.

Think of it this way: If safety in production is a house, then process stability is the foundation. Without a stable foundation, even the strongest house will collapse.

The core goal of this system is to keep critical process parameters—like temperature, pressure, and flow rate—within safe operating windows. It also ensures that control systems, alarms, and interlocks remain sensitive and reliable. The system focuses on streamlining operational procedures, inspections, and shift management, while ensuring seamless coordination among equipment, materials, personnel, and the environment.

Common “Process Instability” Issues in Enterprises

Despite process stability being included in safety standards, many enterprises still struggle to effectively implement it. Some common issues include:

Lack of Management Focus

Many companies lack specific goals, budgets, and clearly defined responsibilities related to process stability. The absence of a PDCA (Plan-Do-Check-Act) cycle means the system isn’t continuously improved, and issues are often addressed reactively rather than proactively.Insufficient Planning and Risk Identification

Risk analyses (such as HAZOP) are often only performed as a formality. Recommendations may be left unimplemented, and high-risk points may not be reassessed dynamically, leaving hidden hazards that can lead to disaster.Training and Resource Shortages

Many employees are unaware of what “process stability” entails or how to identify key parameters or abnormal trends. Training is often vague, with no clear standards for specific job requirements or certifications.Operational Management Chaos

Problems like outdated operating procedures, improper alarm prioritization, inconsistent interlock logic, and poor equipment change management can lead to automatic protection failure. Incomplete inspection records and missing handover information may also trigger incidents.Lack of Performance Assessment

Many companies do not incorporate process stability indicators (like alarm rates or stability rates) into their performance assessments. Without tracking and analyzing key metrics, there is little motivation to improve.

How to Achieve Process Stability?

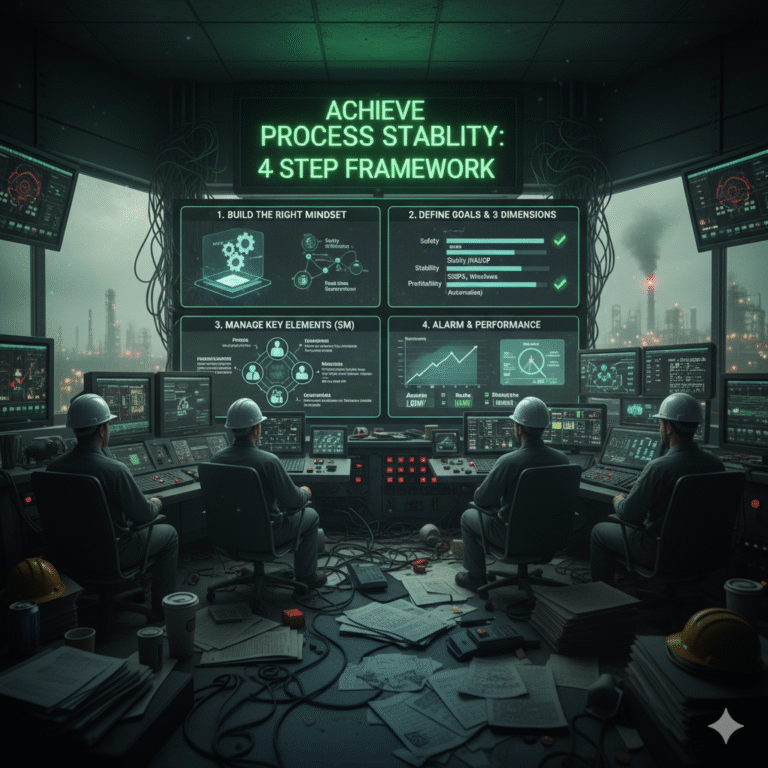

Building a process stability management system is not an overnight task—it’s an ongoing management and execution challenge. Here’s a four-step approach:

Build the Right Mindset

Process stability must be regarded as a strategic priority. Companies should adopt a “triple-win” mindset, where safety, efficiency, and development work together. Additionally, a “four-dimensional management” approach should be adopted:All Employees Involved: Everyone from operators to management should take responsibility.

Full Process Control: Every stage, from raw material input to product output, should be monitored.

Real-Time Monitoring: The entire production process should be visualized.

Comprehensive Supervision: This includes monitoring equipment, electrical systems, instruments, personnel, and the environment.

Define Clear Goals and Control “Three Dimensions”

Process stability management impacts not only safety but also efficiency and profitability. Companies should focus on three key dimensions:Safety: Complete HAZOP analysis before new installations; proactively address hazards and conduct regular maintenance on critical equipment.

Stability: Establish maintenance schedules, define safe operational windows, and create visual operation guides to standardize practices.

Profitability: Optimize product structure, reduce energy consumption, and increase automation to minimize human intervention.

Strengthen Management of Key Elements (People, Equipment, Materials, Methods, Environment)

Achieving stability relies on the following five basic elements:People: Implement a training system to ensure that all employees understand the process, can operate equipment, and handle abnormalities.

Equipment: Enforce comprehensive maintenance, monitoring, and traceability throughout the equipment’s lifecycle.

Materials: Implement strict monitoring of raw materials to prevent fluctuations from impacting the process.

Methods: Establish a rigorous change management system that includes technical, economic, and risk assessments for any modifications.

Environment: Standardize inspection routes, establish clear site markings, and implement information-based monitoring at key points.

Set Appropriate Alarm Indicators and Implement Scientific Performance Evaluation

Alarms are the “health signals” of the process, not just error alerts. Too many alarms suggest instability, while zero alarms might indicate issues being hidden or over-suppressed. The correct approach is:Use trend analysis to identify root causes of frequent alarms.

Optimize alarm prioritization and response logic.

Incorporate “alarm rate” and “stability rate” into performance assessments.

Encourage staff to handle abnormalities properly instead of avoiding alarms.

Conclusion

Establishing a process stability management system is a crucial step for companies transitioning from “passively preventing accidents” to “actively controlling risks.” It helps organizations move beyond learning from past incidents to implementing a proactive, systematic approach to operational safety.

As the saying goes:

“Safety is not created by control, but by stable operations.”

Only by ensuring that every valve, every parameter, and every person is under control can chemical production truly achieve stability, safety, and long-term success.